Air conditioner oil return system, method and air conditioner

An oil return system, air conditioner technology, applied in refrigeration safety arrangements, refrigerators, lighting and heating equipment, etc., to achieve the effect of improving the heat exchange effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

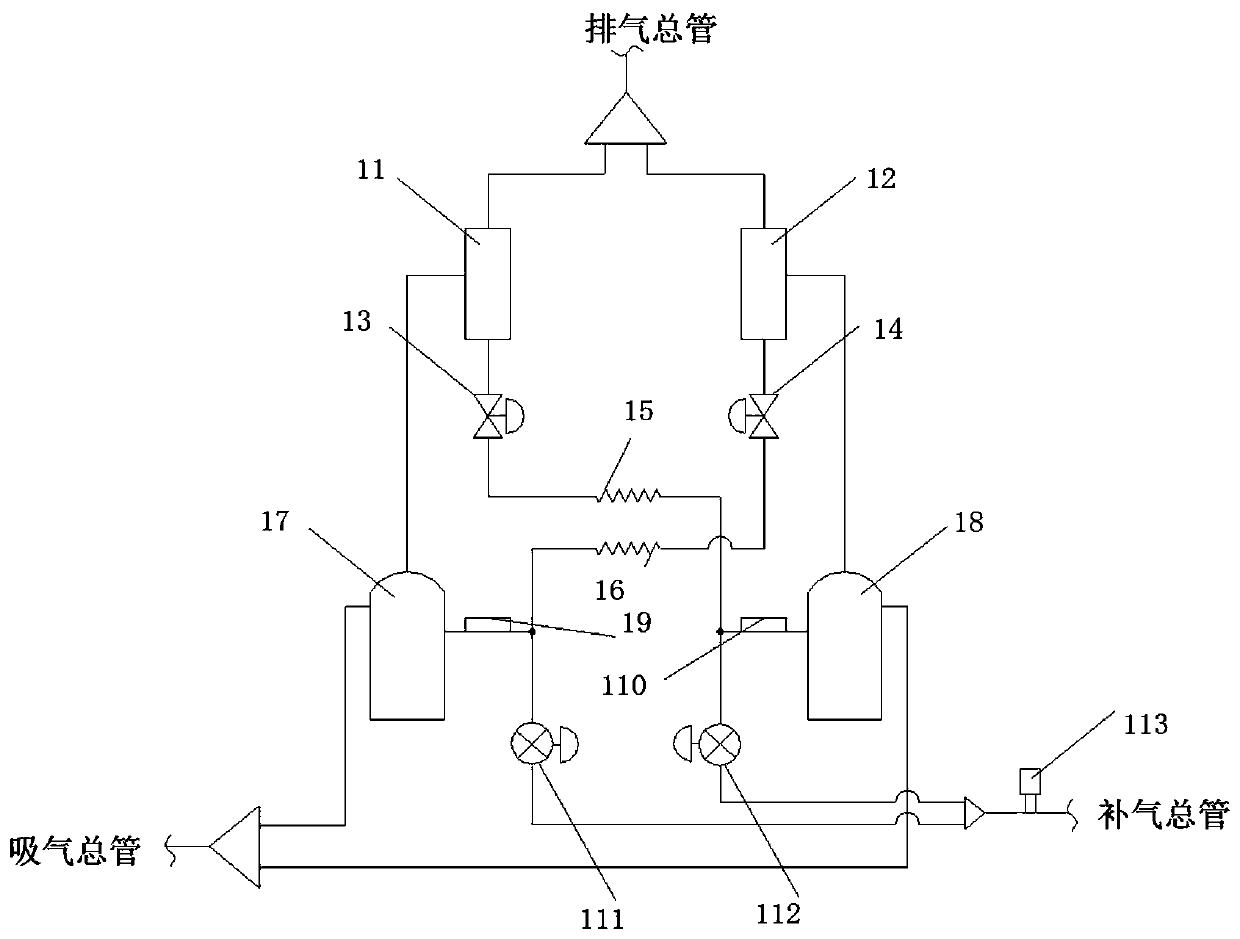

[0020] This embodiment provides an air conditioner oil return system, the air conditioner oil return system mainly includes the following components:

[0021] An oil separator, an oil return pipeline, and a controller, wherein the inlet of the oil separator is connected to the exhaust port of the compressor in the air conditioner, and is used to receive the oil-air mixture discharged from the compressor connected to it, and transfer the oil-air mixture Separation; the oil return pipeline is used to deliver the oil separated by the oil separator to the compressor in the air conditioner, which can be any one of the multiple compressors in the air conditioner system; the controller is used to return the oil in the air conditioner During operation, the air supply flow rate in the air supply circuit of the compressor is adjusted according to the air supply superheat of the compressor in the air conditioner, so as to reduce the oil return temperature of the air conditioner.

[0022]...

Embodiment 2

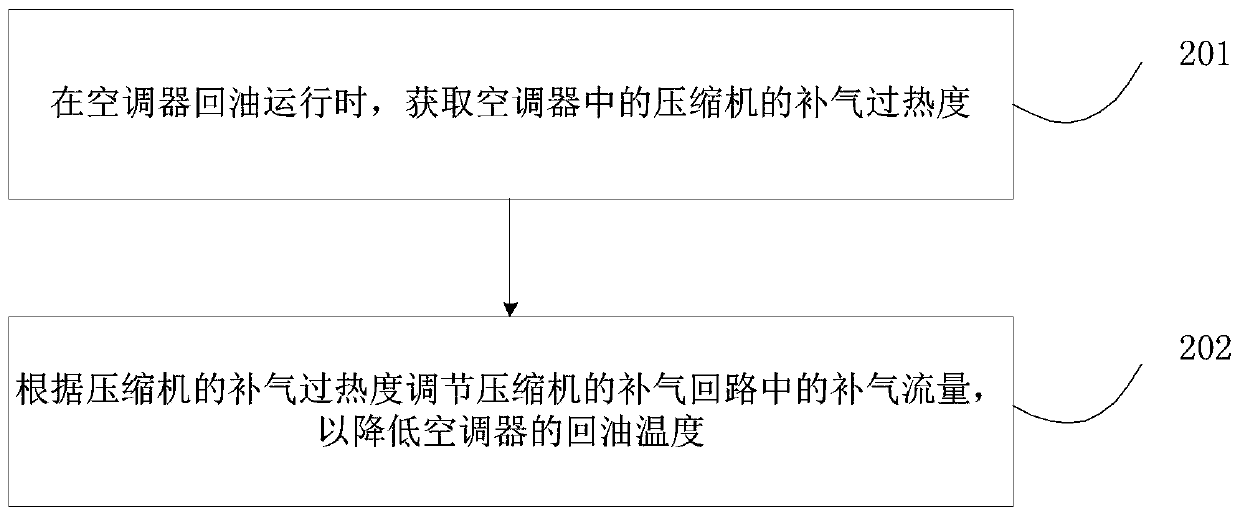

[0029] This embodiment provides an air conditioner oil return method, which can be executed by the air conditioner provided in Embodiment 1 above, figure 2 is the flowchart of the method, such as figure 2 As shown, the method includes the following processing:

[0030] Step 201: When the air conditioner is in oil return operation, obtain the superheat degree of the compressor in the air conditioner;

[0031] Wherein, the method for obtaining the superheat degree of the supplementary air of the compressor in the air conditioner has been introduced in the above-mentioned embodiment 1, and will not be repeated here.

[0032] Step 202: Adjust the air supply flow in the air supply circuit of the compressor according to the air supply superheat of the compressor, so as to reduce the oil return temperature of the air conditioner.

[0033] In this embodiment, the operation of adjusting the supplementary air flow in the supplementary air circuit of the compressor according to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com