Ash deposition resistance and acid dew corrosion resistance heat exchanger accurate in positioning and easy for side leakage

An accurate positioning and heat exchanger technology, applied in acid dew corrosion-resistant heat exchangers and anti-dust fields, can solve the problems of difficult to guarantee the life of heat exchange tubes, easy to generate vibration, poor heat exchange efficiency, etc., to solve the problem of corrosion Problems and fouling problems, easy operation and management, accurate and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

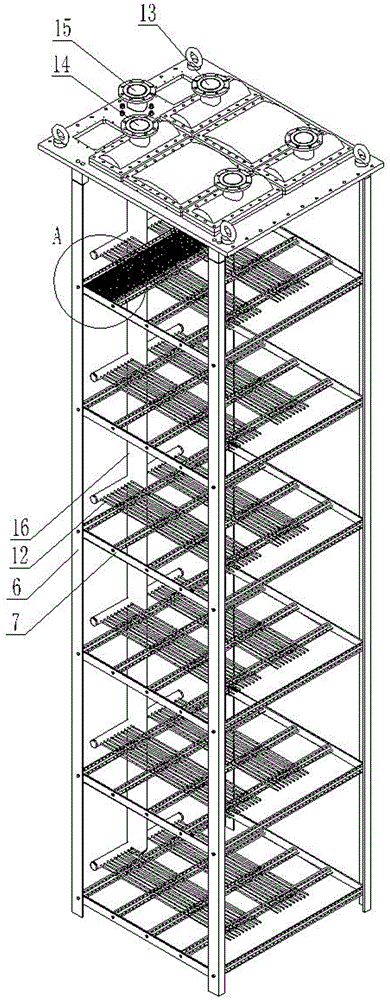

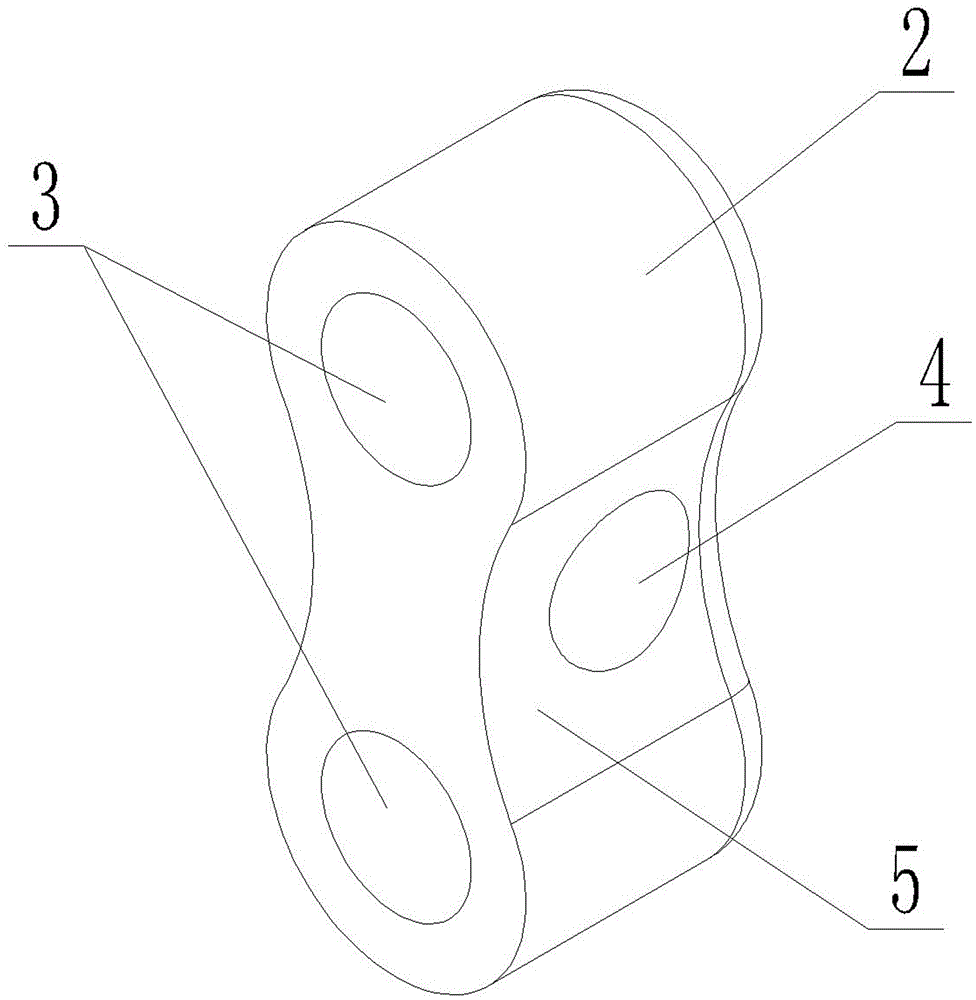

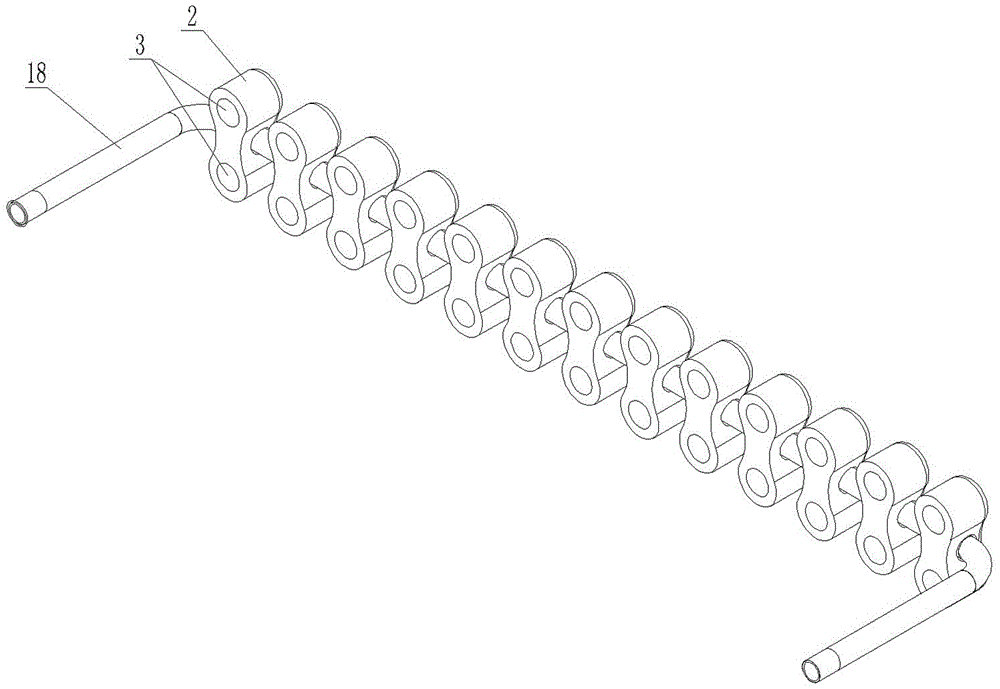

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] as attached Figure 1-6As shown, a heat exchanger with accurate positioning and easy side leakage, anti-dust accumulation, and acid dew corrosion resistance includes a support frame, a three-wing connector connected to the support frame, and a hook 18 connected to the adjacent three-wing connector The 8-shaped blocks between them and the fluoroplastic heat exchange tubes passing through the 8-shaped blocks to form a mesh heat exchange grid. The 8-shaped block includes a block body 2, a fluoroplastic heat exchange tube positioning through hole 3 arranged on the end surface of the block body 2 for the fluoroplastic heat exchange tube to pass through, and a hook 18 arranged on the side of the block body 2 for passing through Each 8-shaped block is provided with two fluoroplastic heat exchange tube positioning through holes 3 and one positioning through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com