Method for controlling biological slime of clean circulating water system through physicochemical-superconduction high gradient magnetic separation (HGMS) coupled process

A technology for purifying circulating water and biological slime, which can be used in water treatment parameter control, chemical instruments and methods, special compound water treatment, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

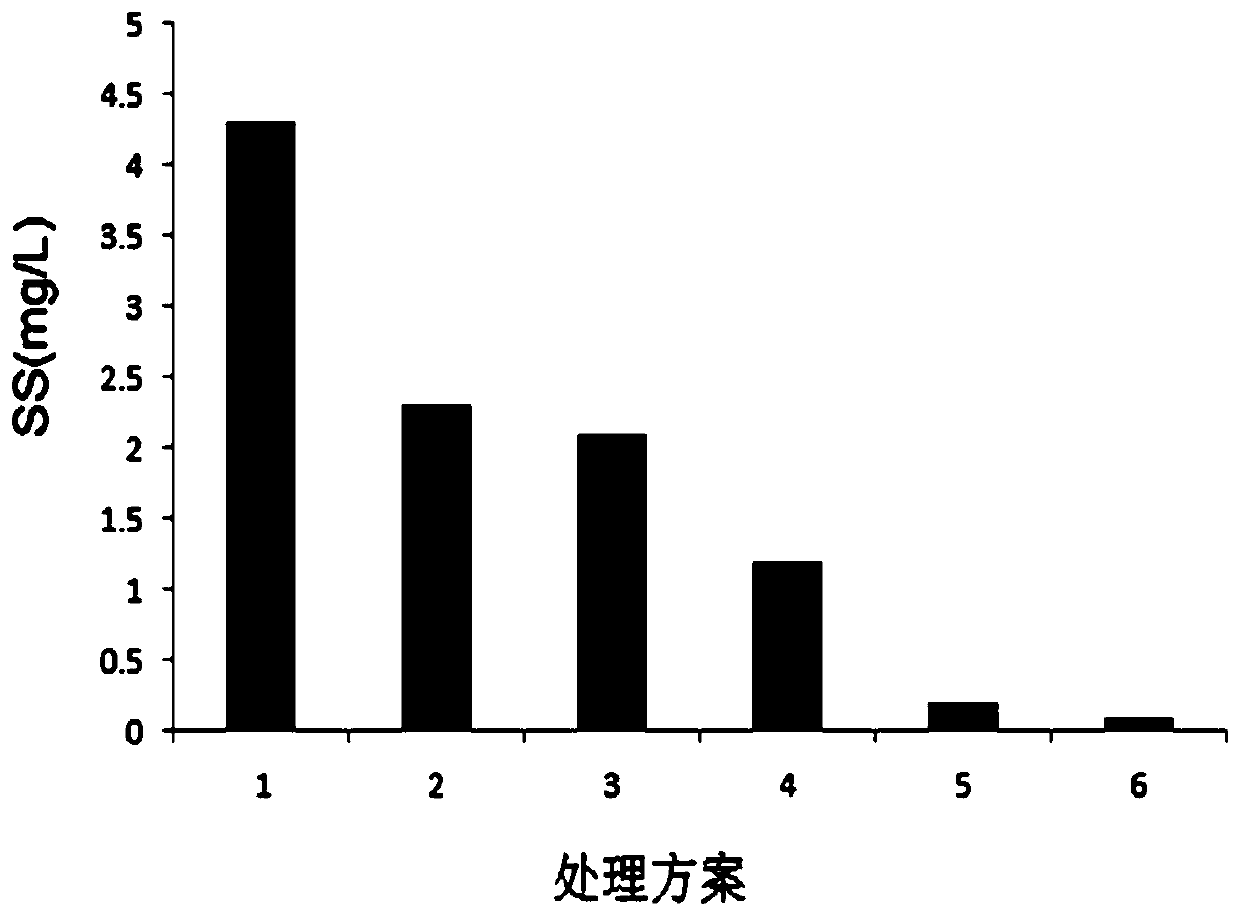

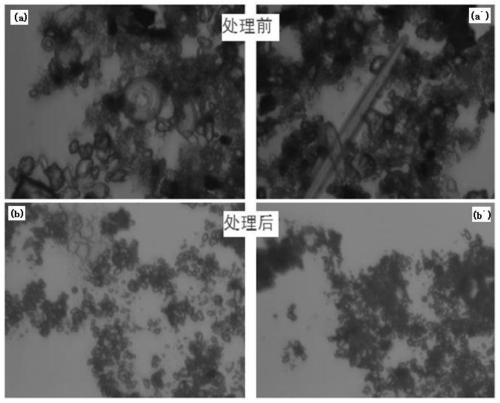

[0026] Taking the clean circulating water of the air separation system of an oxygen plant, which has the most stringent water quality requirements, as the research object, an industrial test is carried out. SS 21.5mg / L in raw water, at a magnetic field strength of 3.0T, flocculant (composed of 20-50% sodium silicate, 20-40% iron sulfate, 20-40% zinc sulfate and 5-30% sodium borate) was added Under the conditions of 30mg / L flow rate and 0.4-4mm / s flow rate, after flocculation-superconducting coupling treatment, a relatively ideal treatment effect is obtained, SS drops to 5mg / L or even undetected level, bacteria and algae are killed, such as figure 1 , figure 2 shown.

Embodiment 2

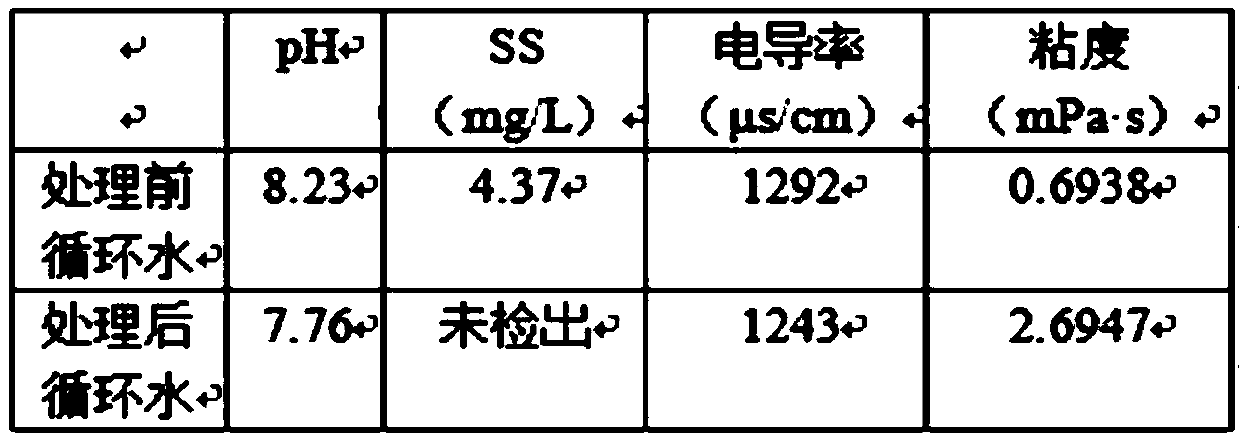

[0028] Taking the clean circulating water of the air separation system of an oxygen plant, which has the most stringent water quality requirements, as the research object, an industrial test is carried out. SS 4.37mg / L in raw water, at a magnetic field strength of 4.0T, flocculant (composed of 20-50% sodium silicate, 20-40% iron sulfate, 20-40% aluminum sulfate and 5-30% sodium borate) was added Under the conditions of 30mg / L flow rate and 0.4-4mm / s flow rate, after flocculation-superconducting coupling treatment, the ideal treatment effect was obtained, and SS dropped from 4.37mg / L to undetected level (see Table 1 below), and bacteria and algae were killed The killing effect is remarkable.

[0029] Table 1 Removal effect of SS in net circulating water of air separation system in oxygen plant

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com