Novel cooling equipment

A cooling equipment, a new technology, applied in the direction of heat exchange equipment, lighting and heating equipment, heat exchanger types, etc., can solve the problems of effective gas composition loss, high power consumption, difficult gas-water separation, etc., to achieve fine and smooth texture, Good heat exchange effect, not easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

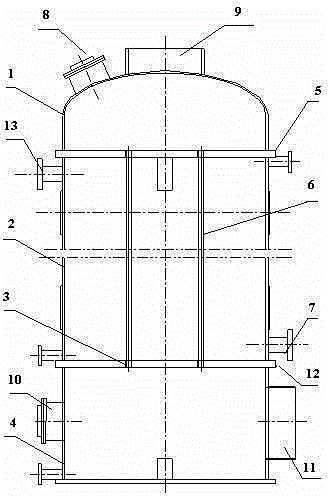

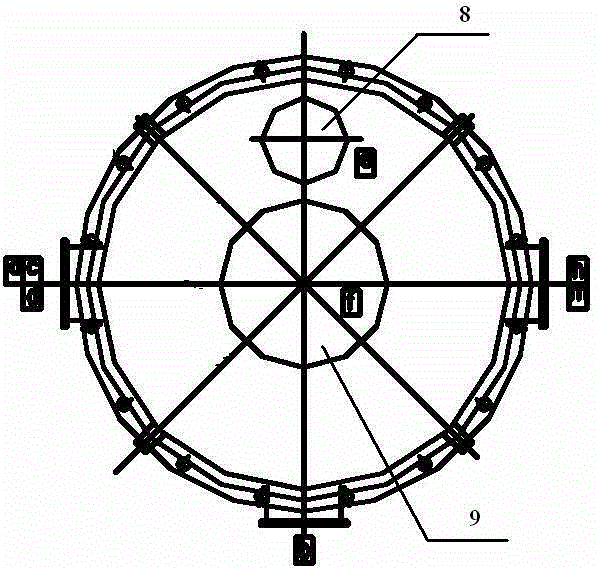

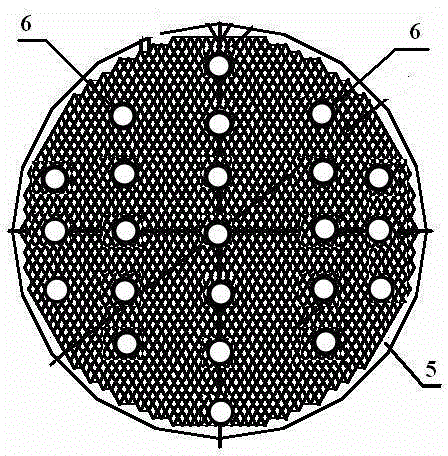

[0022] see figure 1 , figure 2 and image 3 As shown, the upper head 1 is provided with an observation port 8, the heat exchange tube 6 and the upper tube sheet 5 are elastically sealed and connected by a sealing ring 3, and the heat exchange tube 6 and the lower tube sheet 12 are connected by an elastic sealing ring 3 . The semi-water gas enters the device from the material inlet 9 on the upper head 1, enters the lower head 4 after passing through the heat exchange tube 6, and then discharges from the lower head 4 through the material outlet 11; the cooling water passes through the cooling water inlet of the shell 2 7 enters the housing 2 and flows out from the cooling water outlet 13 after being deflected by the baffle plate. The maintenance port 10 is arranged on the lower head 4, which is convenient for equipment maintenance....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com