Production method for preparing natural ore or red soil into ultrafine powder

A technology of ultra-fine powder and natural ore, which is applied in grain processing and other directions to achieve the effect of increasing product qualification rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

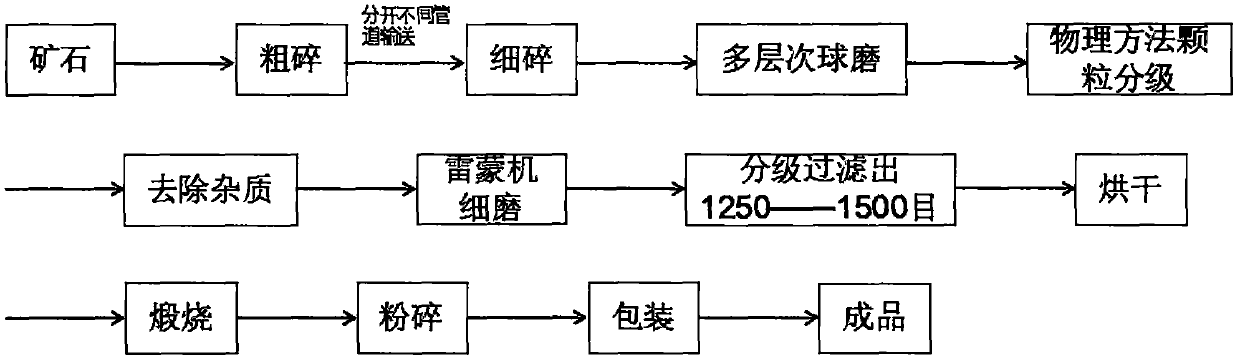

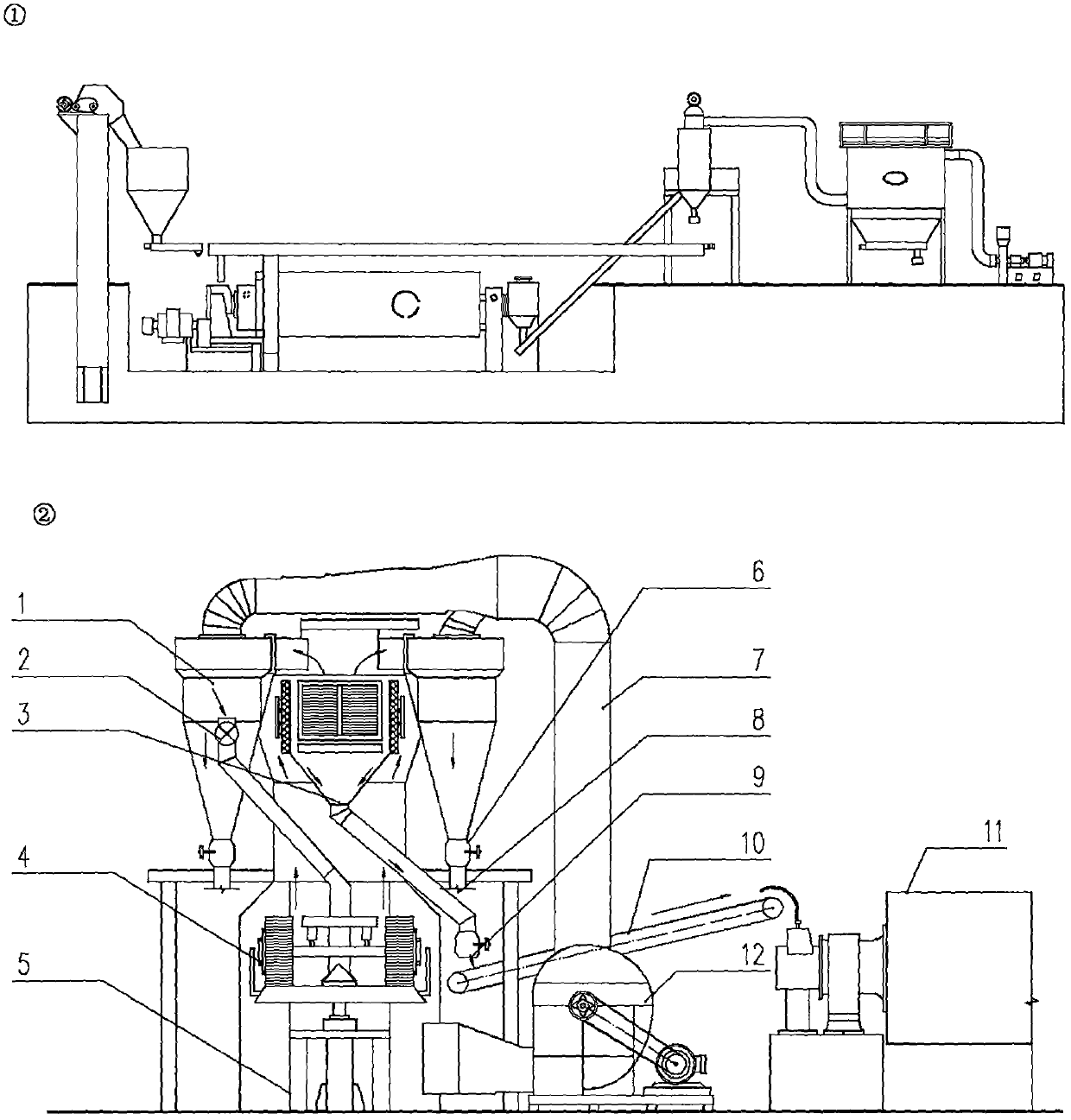

[0020] A method for developing natural ore or red clay into super fine powder, including figure 1 And attached figure 2 Follow the steps below:

[0021] (1) Raw material preparation: Remove miscellaneous stones from the excavated natural ore or laterite, screen out natural ores with color issues, high content of related active ingredients, and highly consistent crystal structure, and send them to the crusher for coarse crushing.

[0022] (2) Fine crushing: The coarsely crushed particles are separated into different pipelines and transported to the multi-level grinding equipment for fine grinding, and the necessary particle uniformity detection and treatment are carried out.

[0023] (3) Multi-level ball milling: from fine grinding to multi-level ball milling, adding organic particles. And pay full attention to the aforementioned technical standards in order to complete the production tasks smoothly.

[0024] (4) Raymond machine use when necessary: after removing impuriti...

Embodiment 2

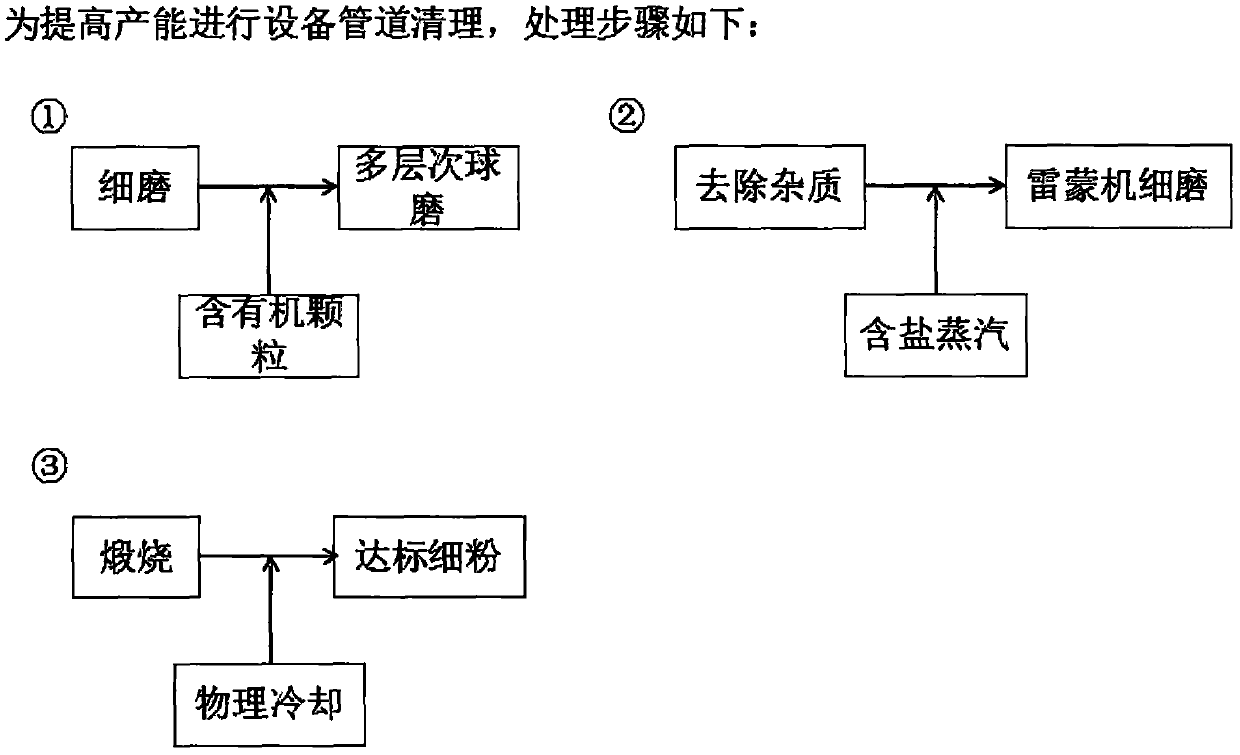

[0027] When the natural ore or red clay material is developed into superfine powder with different product requirements, especially when the superfine ratio is not very high, the main problem will be to improve the labor productivity of qualified products and reduce production costs; the main technology is The implementation of reducing the proportion of unqualified fines may vary. In the case where the requirements for production efficiency are more prominent, the implementation of the inventive method may include additional image 3 The following specific production method steps including the brief diagram:

[0028] (1) Raw material preparation: Remove miscellaneous stones from the excavated natural ore or laterite, screen out natural ores with color issues, high content of related active ingredients, and highly consistent crystal structure, and send them to the crusher for coarse crushing.

[0029] (2) Production of primary products after ball milling: the pulverized parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com