Balance ring of washing machine, inner barrel and washing machine

A balance ring and washing machine technology, applied in the field of washing machines, can solve the problems of limited drainage efficiency, washing water splashing into the outer bucket, etc., and achieve the effect of high drainage and dehydration efficiency, smooth drainage and smooth drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

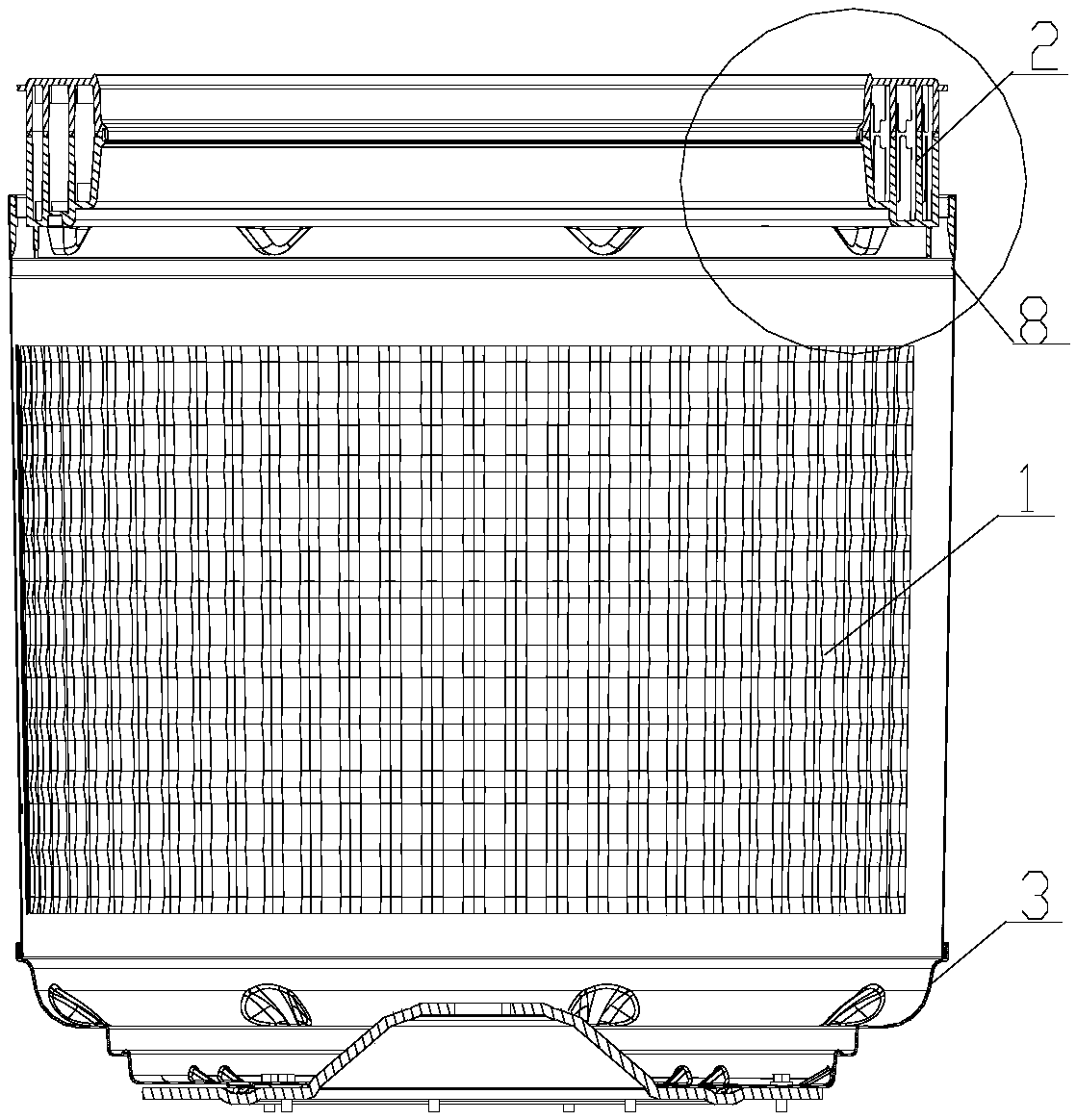

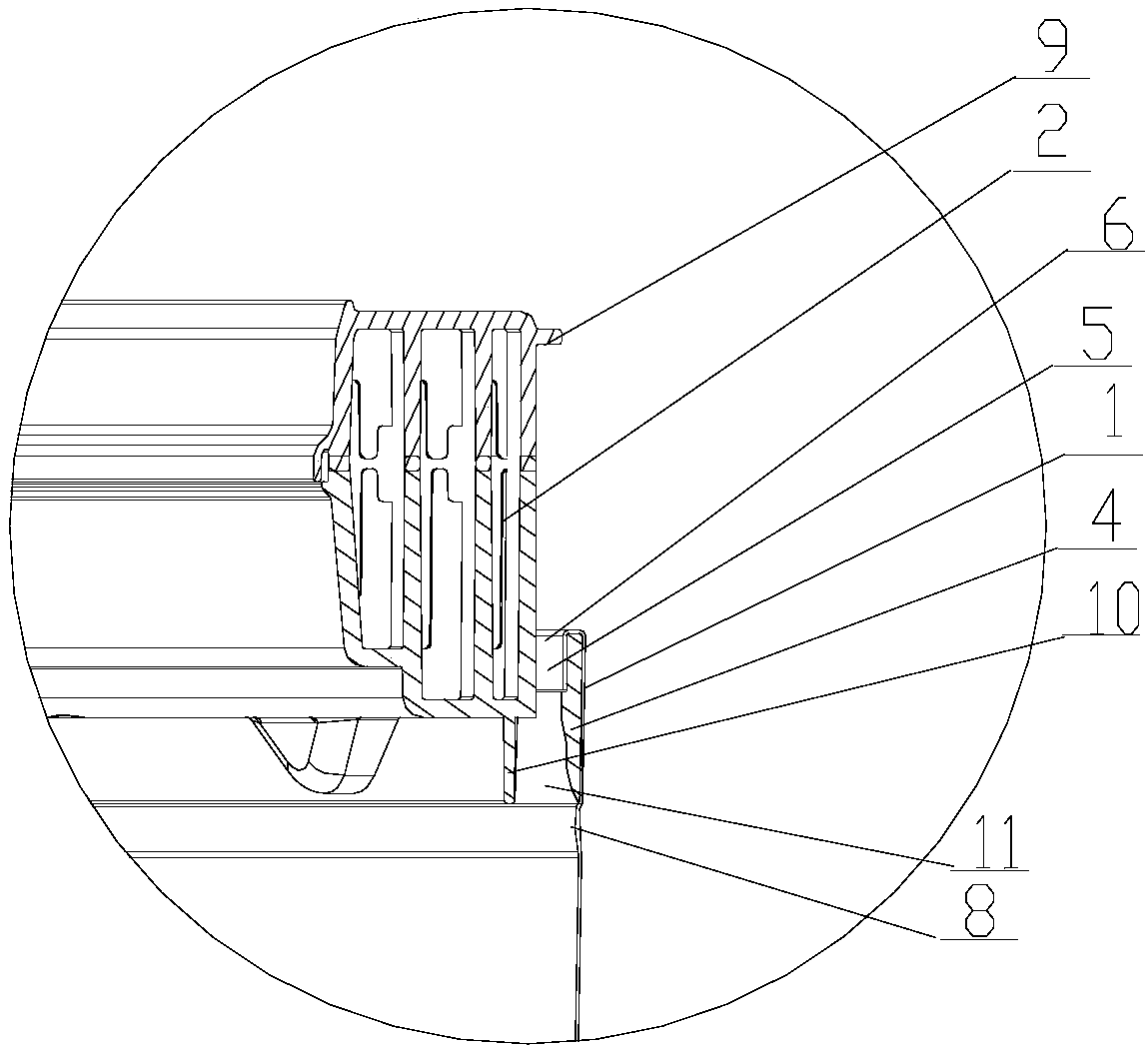

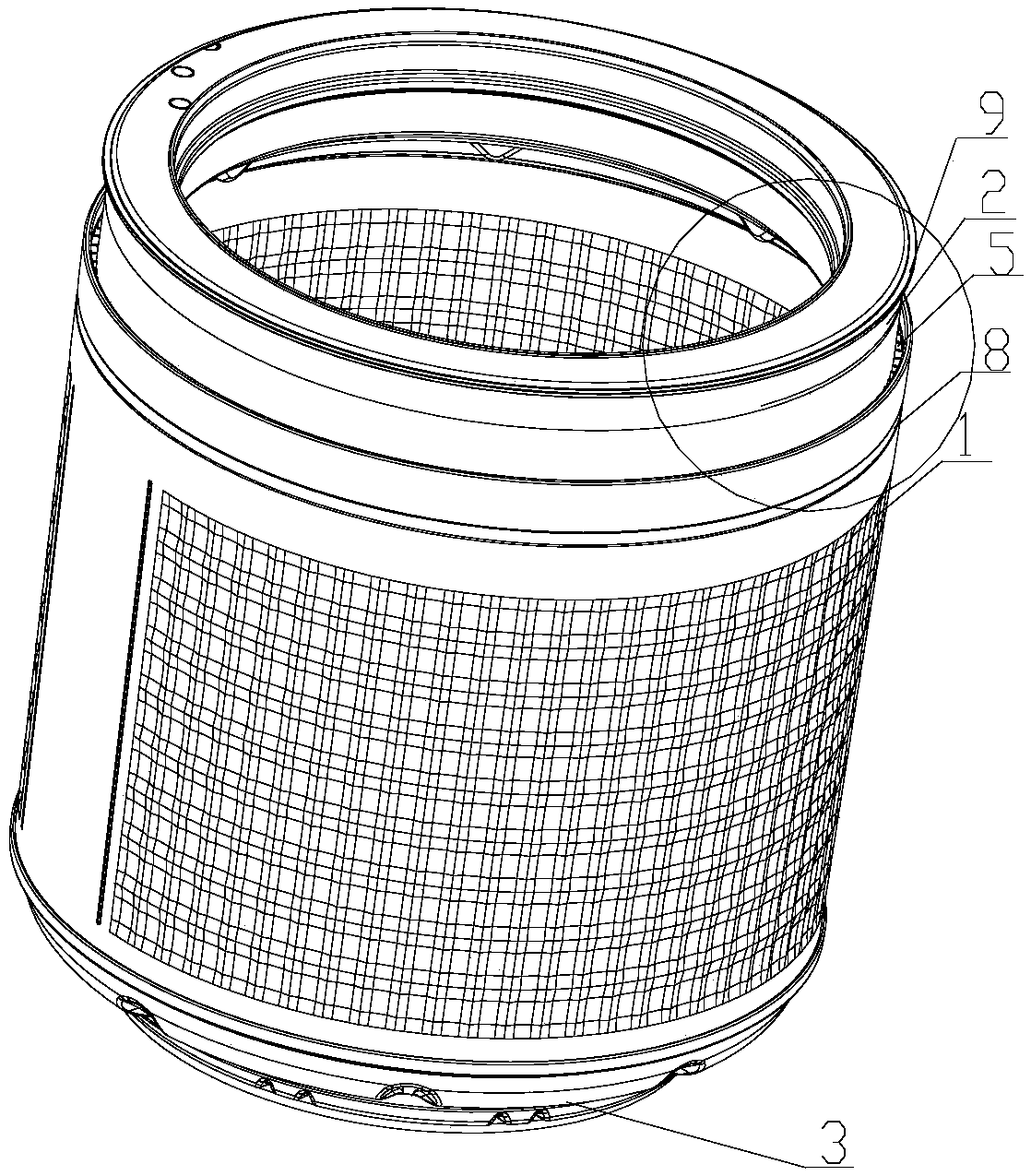

[0046] Such as Figure 1-5 As shown, in the balance ring of a washing machine provided in this embodiment, there is a gap between the annular rib and the balance ring body, and the annular rib and the balance ring body are connected through a connection structure, and a plurality of drainage holes 5 are provided on the connection structure. .

[0047] Connection structure There is a gap between the balance ring body and the annular rib on its outer periphery to facilitate the setting of the top drain hole, and the two are connected by a connection structure, so that the balance ring can be installed by fixing the annular rib, which is simple in structure and easy to fix .

[0048] Further, the connecting structure includes reinforcing ribs 6 and / or annular plates (not marked), so that the following schemes can be adopted between the annular ribs and the gimbal body:

[0049] Method 1: If Figure 4 As shown, the balance ring body 2 and the annular rib 4 are connected by a pl...

Embodiment 2

[0054] Such as Figure 2-4 As shown, the balance ring body 2 of this embodiment is provided with an annular water retaining rib 9 protruding toward the outer periphery of the balance ring body, and the annular water retaining rib is arranged above the water outlet end of the drain hole 5 . The annular water-retaining rib is located above the water outlet of the drain hole, and the distance from the drain hole can block the water that is sprayed quickly, and it is advisable not to hinder the smooth drainage.

[0055] When washing and dehydrating, the rotation speed is extremely high, and the water flow may be ejected rapidly from the drain hole under the action of centrifugal force. The ring-shaped water retaining rib above the drain hole can block the water flow, avoid this situation, and avoid damage to the surrounding environment such as walls. And so on cause bad influence, enhance user experience.

Embodiment 3

[0057] Such as figure 2 As shown, the lower end of the balance ring body of this embodiment is provided with a downward lower annular rib 10 , and there is a gap between the outer wall of the lower annular rib 10 and the inner wall of the annular rib 4 to form a drainage channel 11 .

[0058] Further, the drainage channel is composed of a plurality of longitudinally arranged channels, and at least one drainage hole is provided at the top of each channel;

[0059] Preferably, the channel is mainly composed of the lower annular rib and the longitudinal reinforcing rib and the annular rib.

[0060] In the structure of this embodiment, the top of the inner barrel uses the lower annular rib under the balance ring and the outer peripheral annular rib to form a drainage channel, which is beneficial to the climbing of the water in the inner barrel and is more conducive to smooth drainage; and then cooperates with the longitudinal reinforcing rib to form a plurality of longitudinally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com