Clutch

A clutch device and external friction technology, applied in clutches, power devices, friction clutches, etc., to avoid uncontrollable lubricant backflow and reduce traction torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

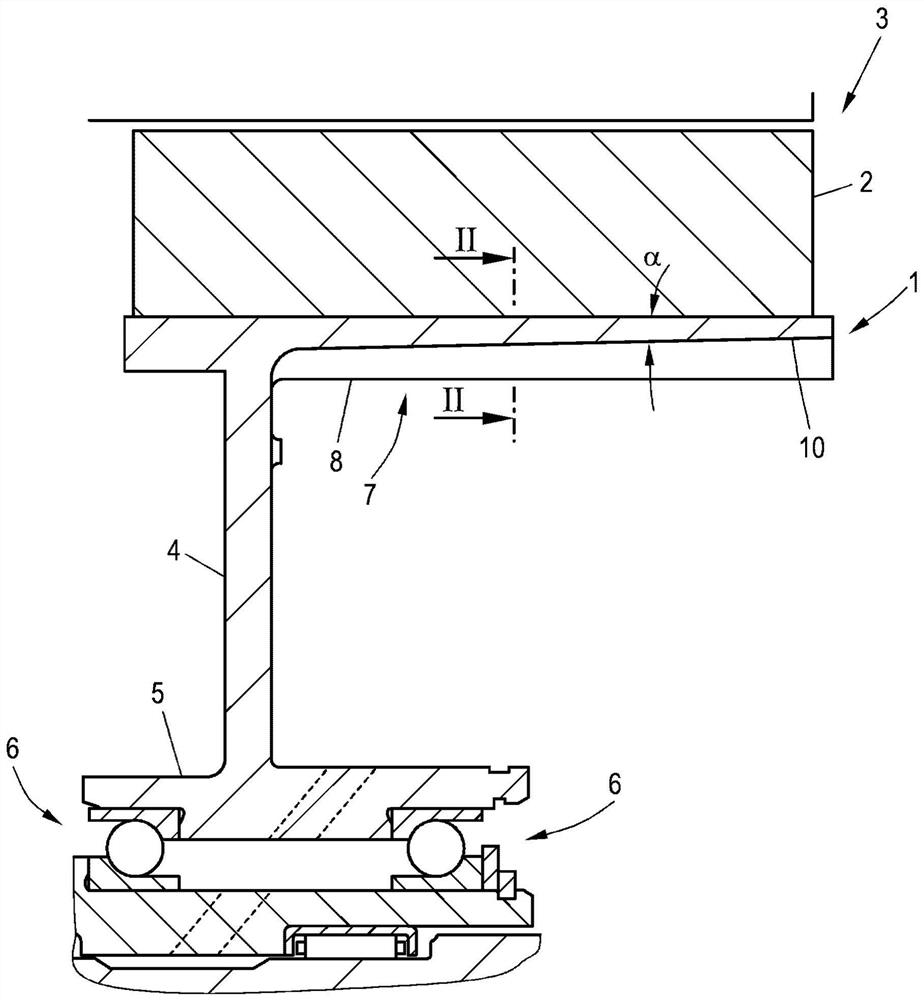

[0023] figure 1 The outer disk carrier 1 according to the invention is shown, in the exemplary embodiment shown, the rotor 2 of the electric machine 3 is connected to the outer disk carrier. As in known solutions, the outer disk carrier 1 is usually part of a known hybrid clutch, which is radially integrated via an annular carrier section 4 and an axially extending bearing section 5 . The position is rotatably supported by the rolling bearing 6.

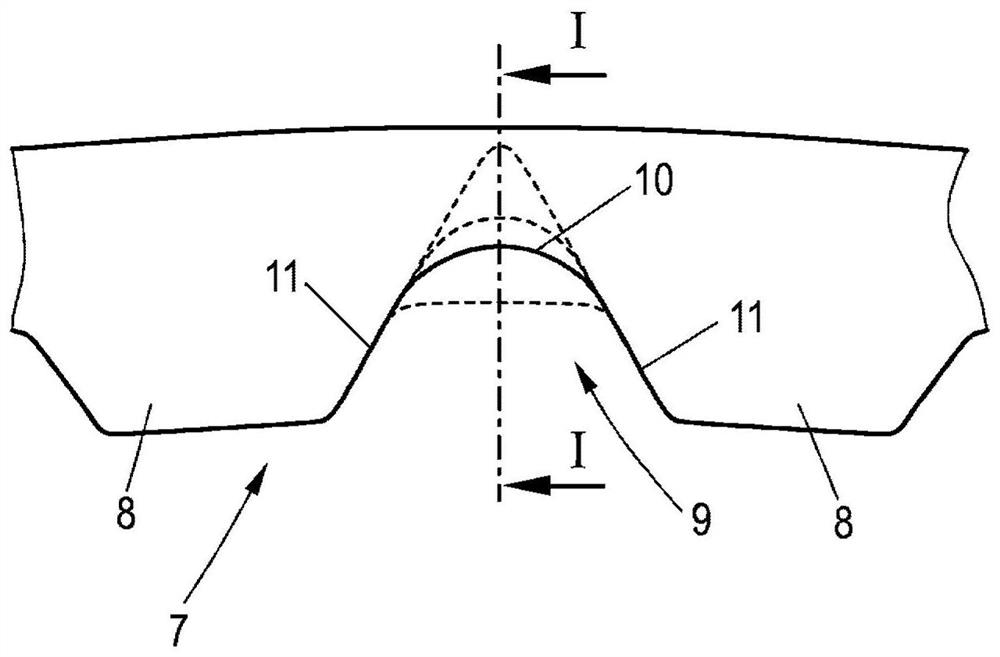

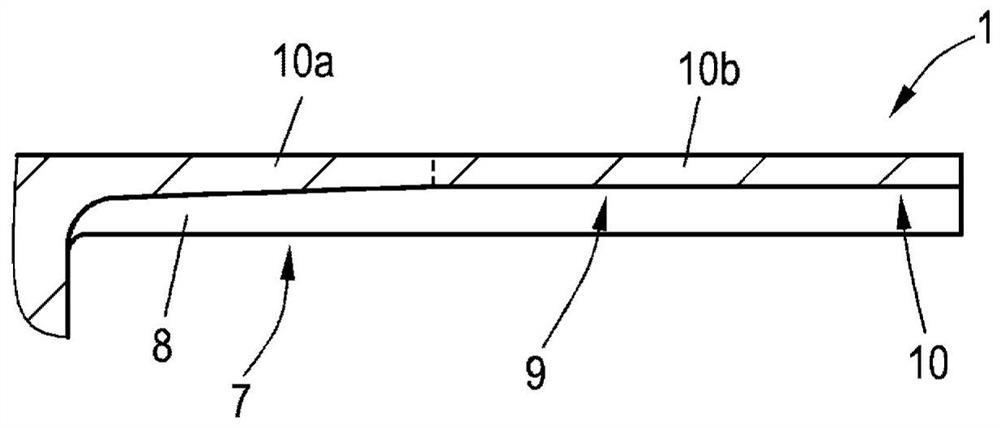

[0024] In known variants, internal toothing 7 is formed on the outer disk carrier 1 , wherein, for the sake of clarity, only the toothing 8 is shown in the sectional view, and not the other toothing rows which are still visible in the sectional view. exist figure 2 The two toothings 8 of the inner toothing 7 are shown in the sectional view along the section line II-II shown in . The teeth 8 are each spaced apart from one another by a groove 9 , wherein the teeth 8 and the grooves 9 extend over the entire length of the outer disk ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com