Wheel-track rolling behavior simulating test stand of wheel track

A technology for simulating test benches and behaviors, applied in railway vehicle testing, machine/structural component testing, measuring devices, etc., can solve problems such as large errors and poor reliability, and achieve precise speed, accurate test basis, measurement data and results precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

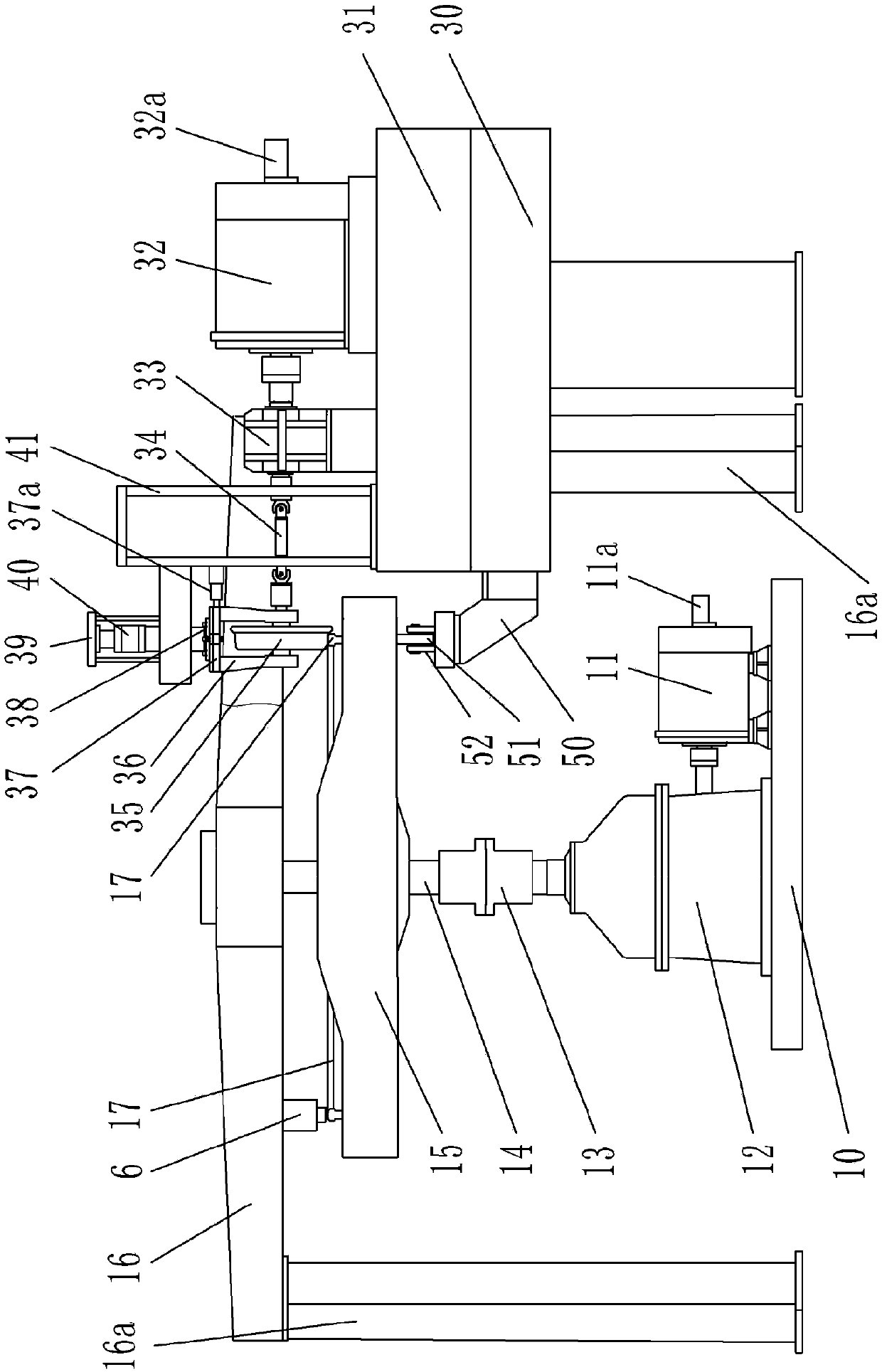

[0028] A specific embodiment of the present invention is a wheel-rail rolling behavior simulation test bench, which consists of:

[0029] see figure 1 , figure 2 , the top of rail base 10 is equipped with rail rotary motor 11, and the right end of rail rotary motor 11 shafts is connected with photoelectric encoder-11a; The lower end of the shaft device 13 is connected, and the upper end of the rotary coupling 13 is connected with the lower end of the high-speed rotary shaft 14; the middle part of the high-speed rotary shaft 14 is equipped with a high-speed rotary disc 15, and the upper end of the high-speed rotary shaft 14 is connected with the support frame 16 through a bearing , the support frame 16 is supported on the ground by the column 16a; a closed rail 17 is installed on the edge of the upper surface of the high-speed rotary disk 15 .

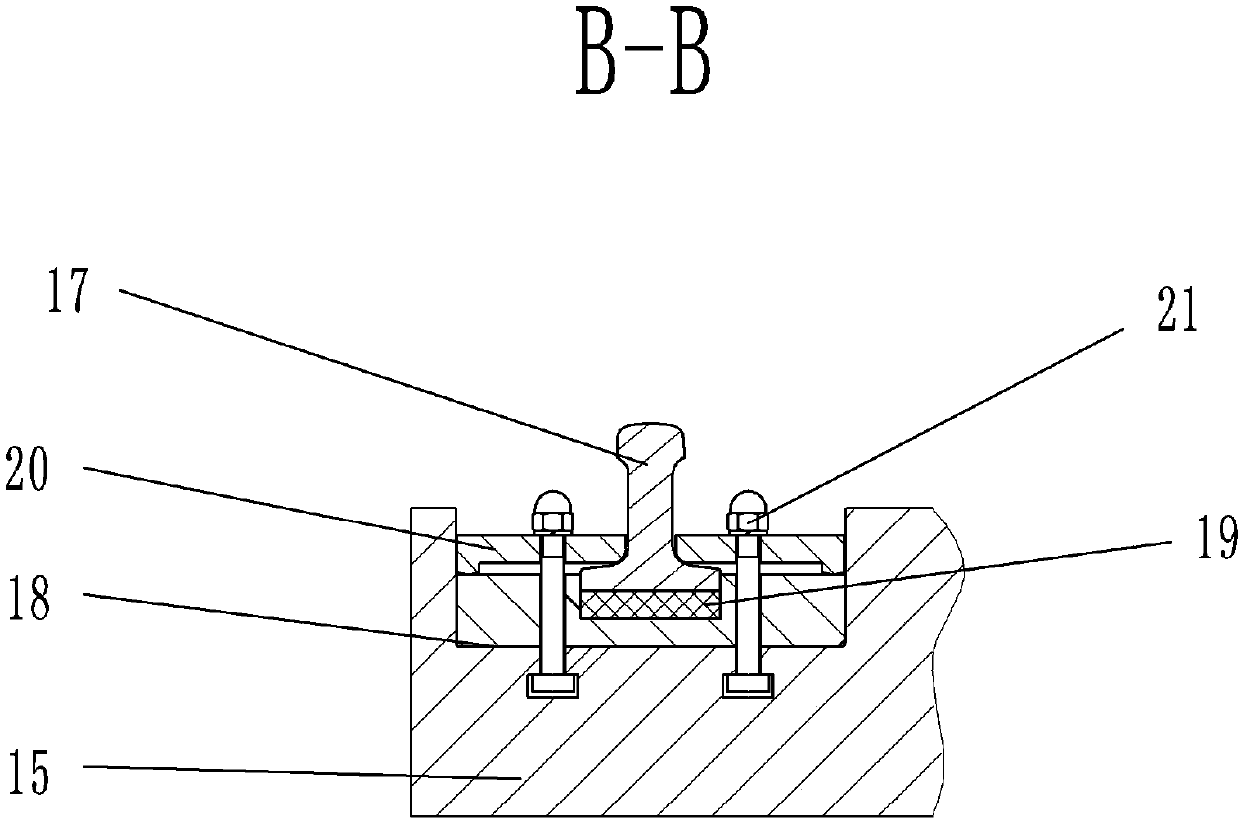

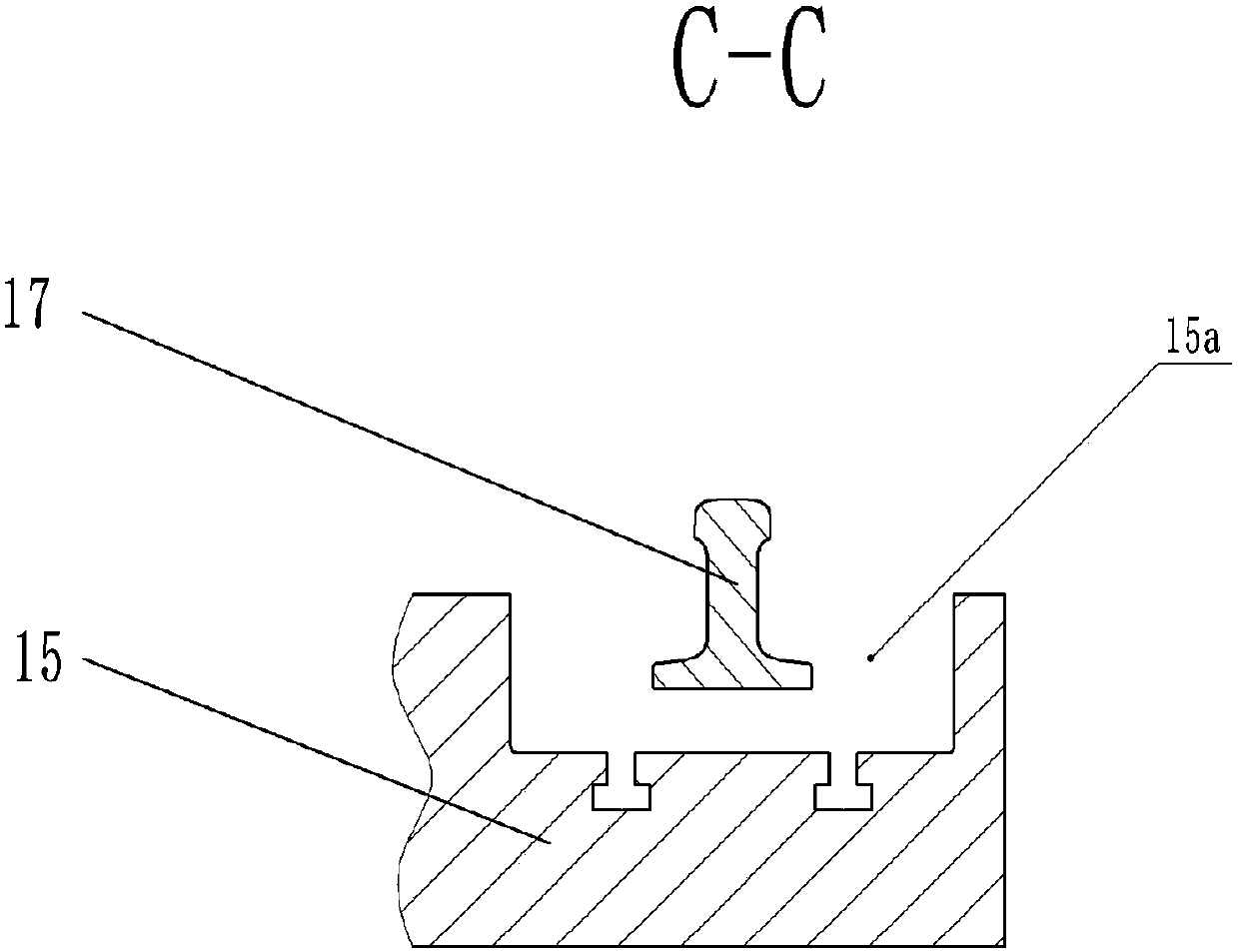

[0030] image 3 and figure 2 , Figure 4 It shows that the edge of the upper surface of the high-speed rotary disk 15 is equipp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap