Structure for strengthening loudspeaker diaphragm, method for strengthening loudspeaker diaphragm and loudspeaker

A loudspeaker and aerogel technology, which is applied in the direction of loudspeakers, sensors, electrical components, etc., can solve the problems of decreased sensitivity of the diaphragm and increase of the total mass of the diaphragm, and achieve good treble effect, high sensitivity, and high rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

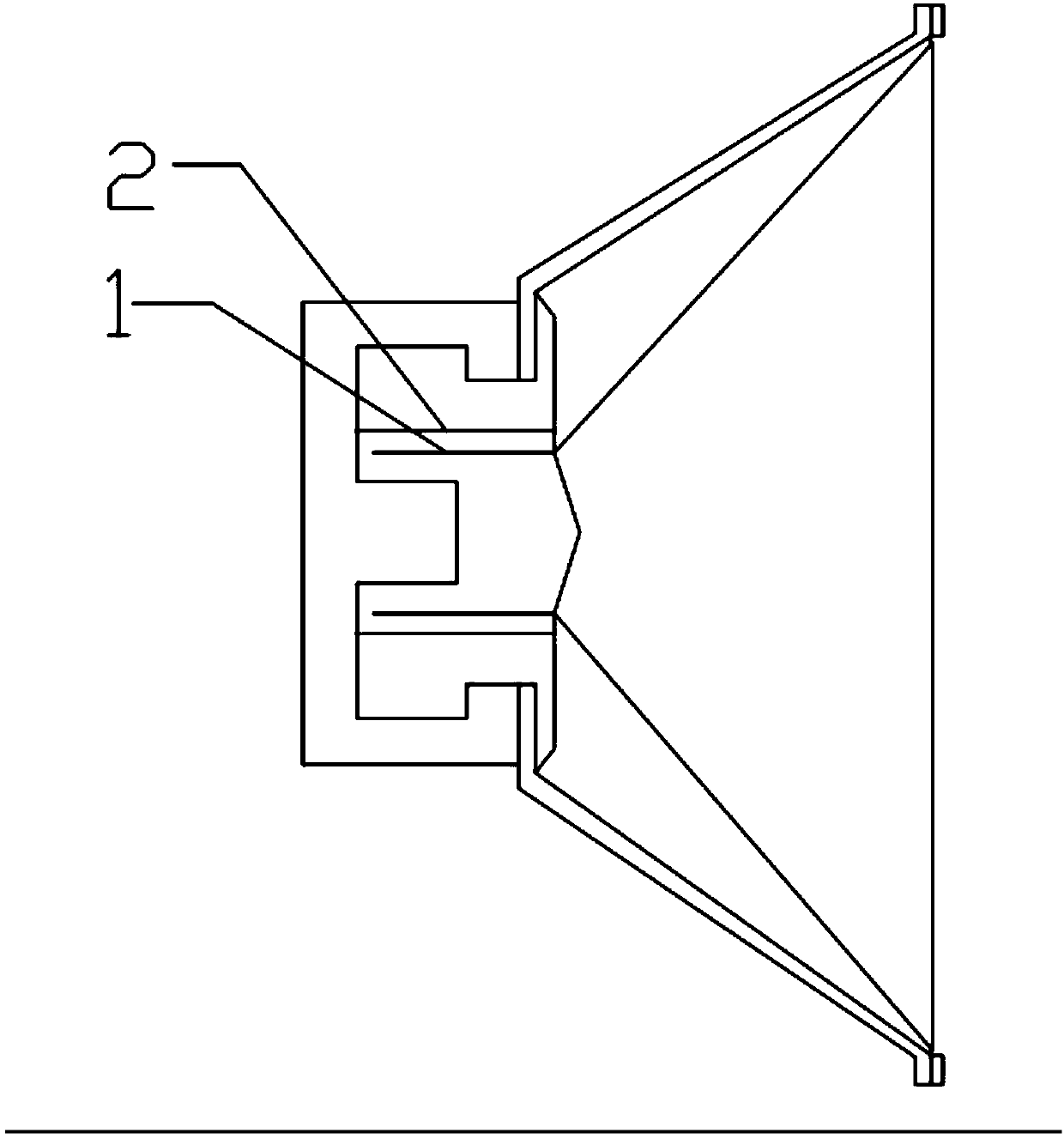

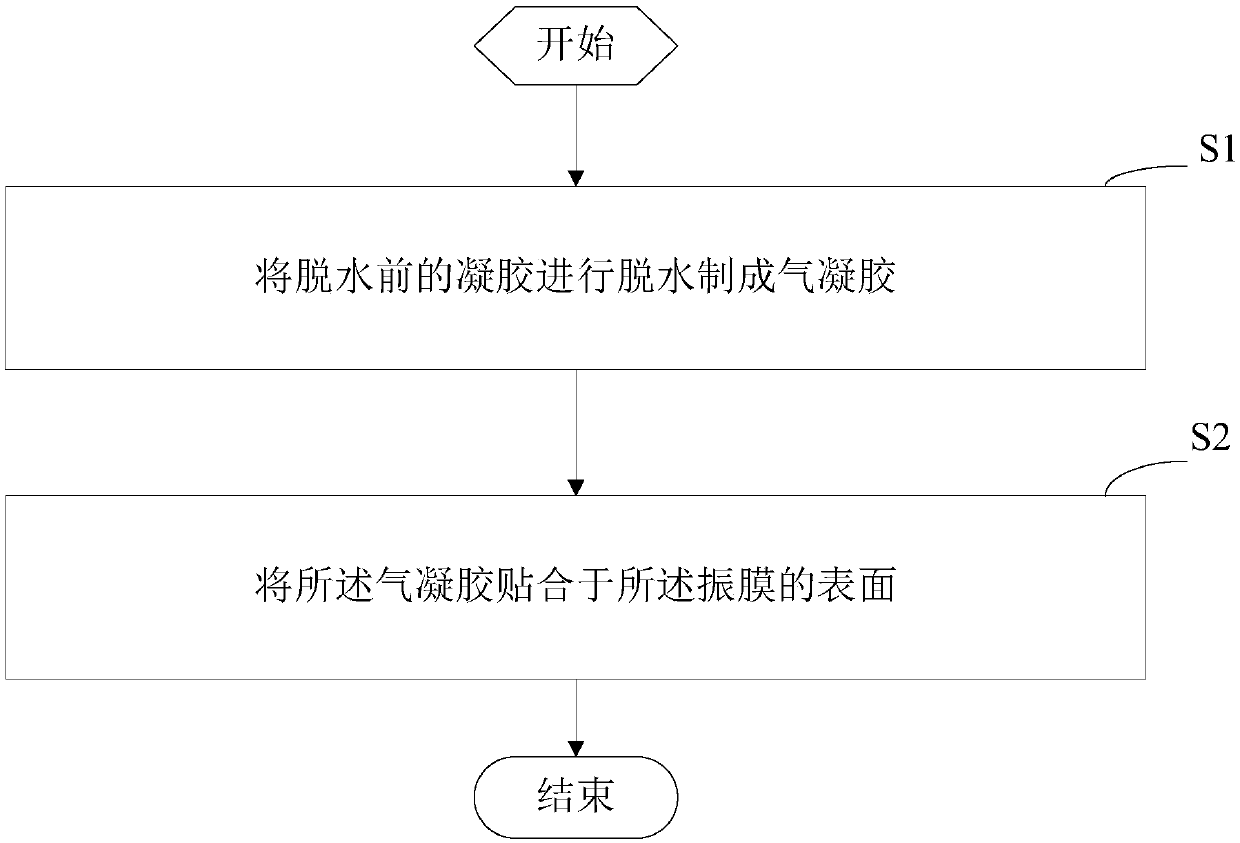

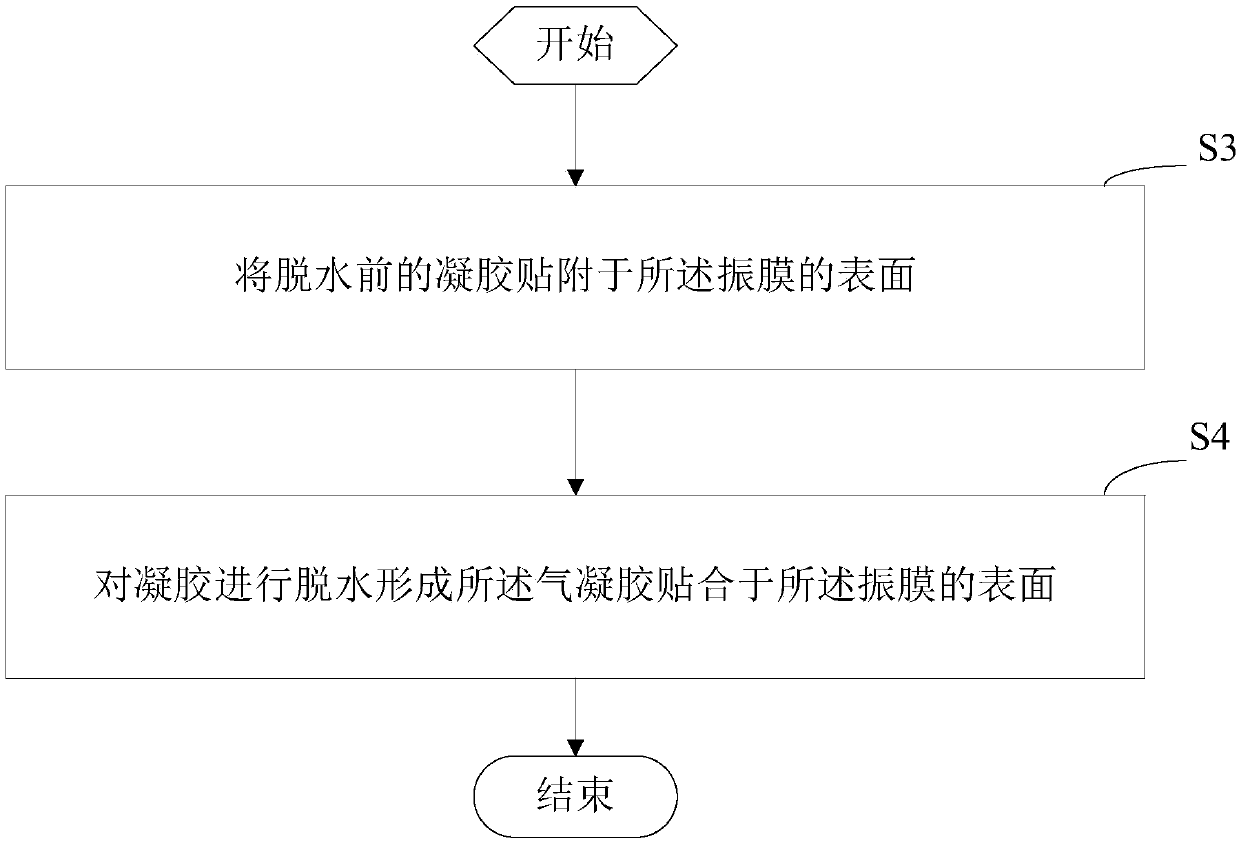

[0025] refer to figure 1 , the structure of the reinforced loudspeaker diaphragm 1 in this embodiment includes airgel 2 and diaphragm 1, the above-mentioned airgel 2 is pasted on the surface of the above-mentioned diaphragm 1, wherein the above-mentioned airgel 2 is the The gel is made by dehydration. Specifically, dehydration is carried out within a shaped frame, and the dehydrated airgel 2 is made into an airgel 2 whose size and shape meet the requirements by cutting or molding processing methods, so that it becomes an integrally formed airgel 2; The glue 2 itself has the characteristics of light weight and high rigidity, and the integrally formed airgel 2 is attached to the surface of the above-mentioned diaphragm 1, so that the diaphragm 1 also has the characteristics of light weight and high rigidity. The coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com