Photocurable resin composition, fuel cell, and sealing method

一种光固化性树脂、燃料电池的技术,应用在光固化性树脂组合物领域,能够解决电解质膜劣化、花费工序时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0132] The components of Example 1 were taken in parts by mass shown in Table 1, and were mixed at room temperature (25° C.) for 60 minutes using a mixer (device name Tornado high output power type PM-202 (manufactured by AS ONE Co., Ltd.), rotating speed: 100 rpm). Minutes, a photocurable resin composition was prepared, and various physical properties were measured as follows. It should be noted that the detailed preparation amounts are in accordance with Table 1, and all numerical values are expressed in parts by mass.

Embodiment 2~9 and comparative example 1~7

[0134] The photocurable resin compositions of Examples 2 to 9 and Comparative Examples 1 to 7 were also prepared in the same manner as in Example 1 using the components taken in parts by mass shown in Table 1 and Table 2, and various physical properties were measured. . It should be noted that the detailed preparation amounts are in accordance with Table 1 and Table 2, and all numerical values are expressed in parts by mass.

[0135]

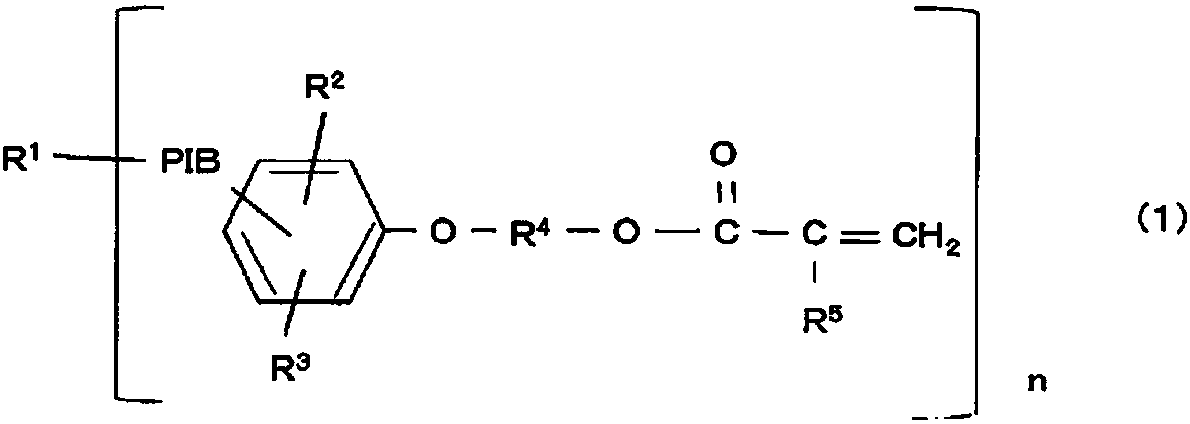

[0136] Production of polyisobutylene polymer (a1) having acryloyloxyethoxyphenyl group

[0137] After substituting nitrogen in the container of the 5 L separable flask, 200 mL of n-hexane and 2000 mL of butyl chloride were added, and cooled to -70°C while stirring under a nitrogen atmosphere. Next, 840 mL (9 mol) of isobutene, 12 g (0.05 mol) of p-dicumyl chloride, and 1.1 g (0.012 mol) of 2-picoline were added. After the reaction mixture was cooled to -70°C, 5.0 mL (0.05 mol) of titanium tetrachloride was added to start polymerization. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com