Measuring and/or inspection system and method of managing associated electrical connections

A technology for inspection systems and electrical connections, applied in the field of measurement and/or inspection systems, which can solve problems such as difficult installation, large size, and inflexibility, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

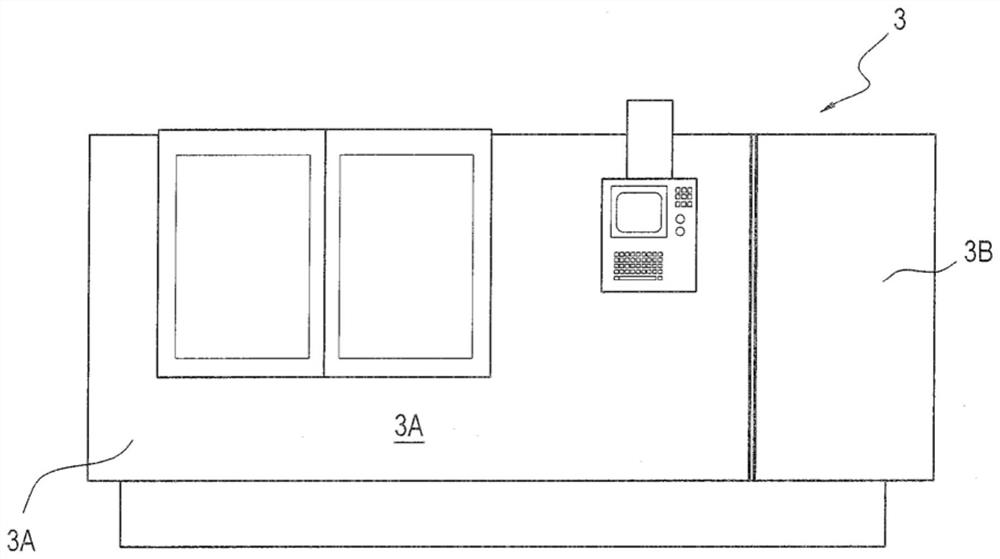

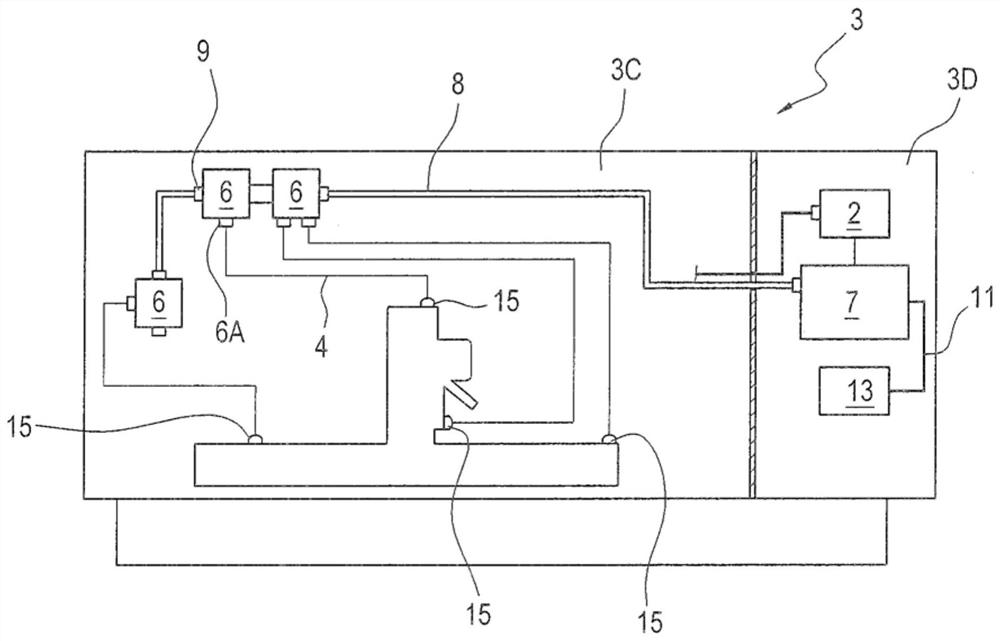

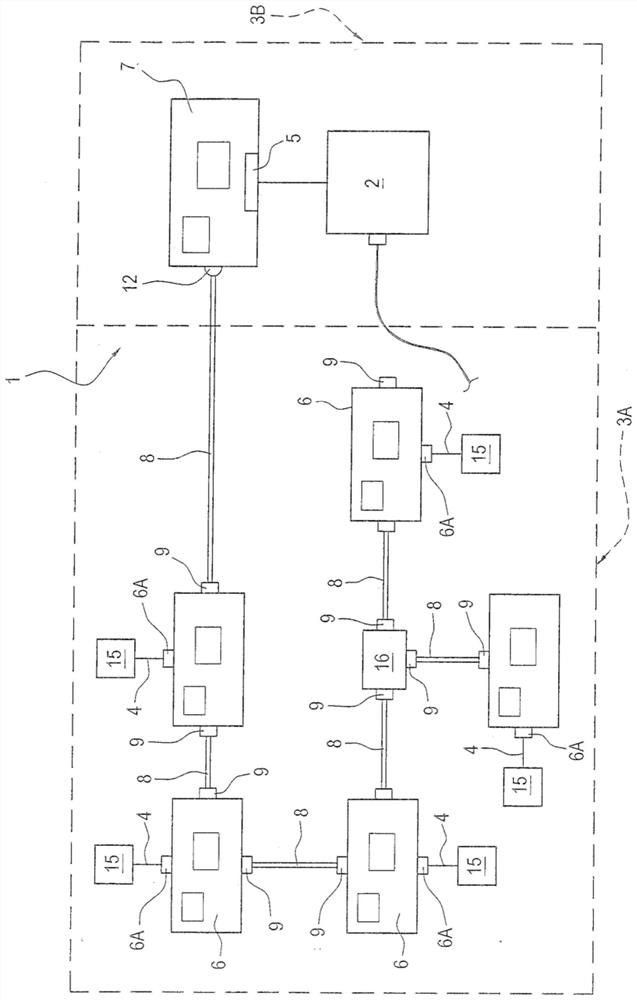

[0088] With reference to the attached figures, reference numeral 1 designates a data processing and transmission system for a numerical control unit 2 suitable for controlling a machine tool 3 .

[0089] The machine tool 3 has a working chamber 3A in which at least one tool is positioned. The working chamber 3A defines its own inner space 3C, that is to say a working space. Typically, workspace 3C constitutes a contaminated (dirty) environment.

[0090] The machine tool 3 also typically includes a switchboard or switchboard 3B in which the numerical control unit 2 is positioned. The switchboard 3B defines its own interior space 3D. The inner space 3D of the switchboard 3B constitutes a relatively clean environment; in fact, it is separated from the working space 3C of the machine tool 3 , for example by a wall.

[0091] The system 1 comprises at least one input channel 4 suitable for transmitting operating signals from or to a device 15 present in the machine tool 3 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com