Assembly line automatic honey extractor

An assembly line, honey machine technology, applied in the direction of honey collection, application, beekeeping, etc., can solve the problems of occupying equipment operation time and low efficiency of the honey shaking process, so as to reduce labor costs, omit idle time, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

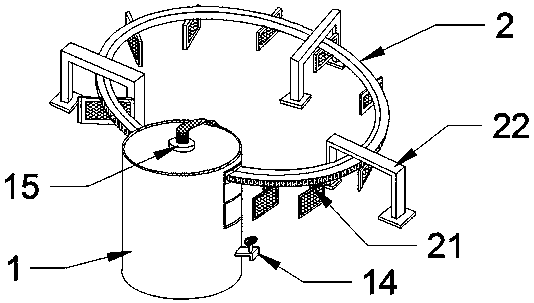

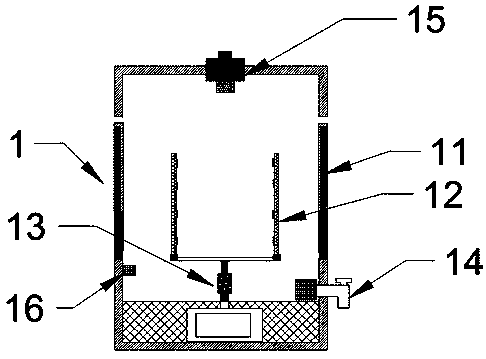

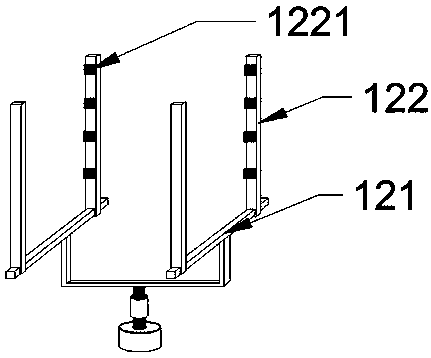

[0022] Such as figure 1 , figure 2 and image 3 As shown, an assembly line automatic honey shaker includes a shaker honey pot 1 and a honeycomb frame 12. Two gaps opposite to each other are arranged on the side of the honey shaker pot 1, and a transmission track 2 runs through the gap, and the transfer track 2 is in the honey shaker pot 1. The outside of the body forms a closed loop. The transmission track 2 is also connected with multiple honeycomb grippers 21. The size of the gap on the honey shaker 1 is larger than the combination of the transmission track 2, the honeycomb gripper 21 and the beehive honeycomb held by it. The size of the body; the gap position of the honey shaker 1 is provided with a telescopic baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com