Steel coil uncoiling automatic locating auxiliary threading system and method

An automatic positioning and steel coil technology, which is applied in the directions of guiding/positioning/alignment devices, instruments, electrical digital data processing, etc., can solve the problems of low efficiency of manual uncoiling and threading, and high risk of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

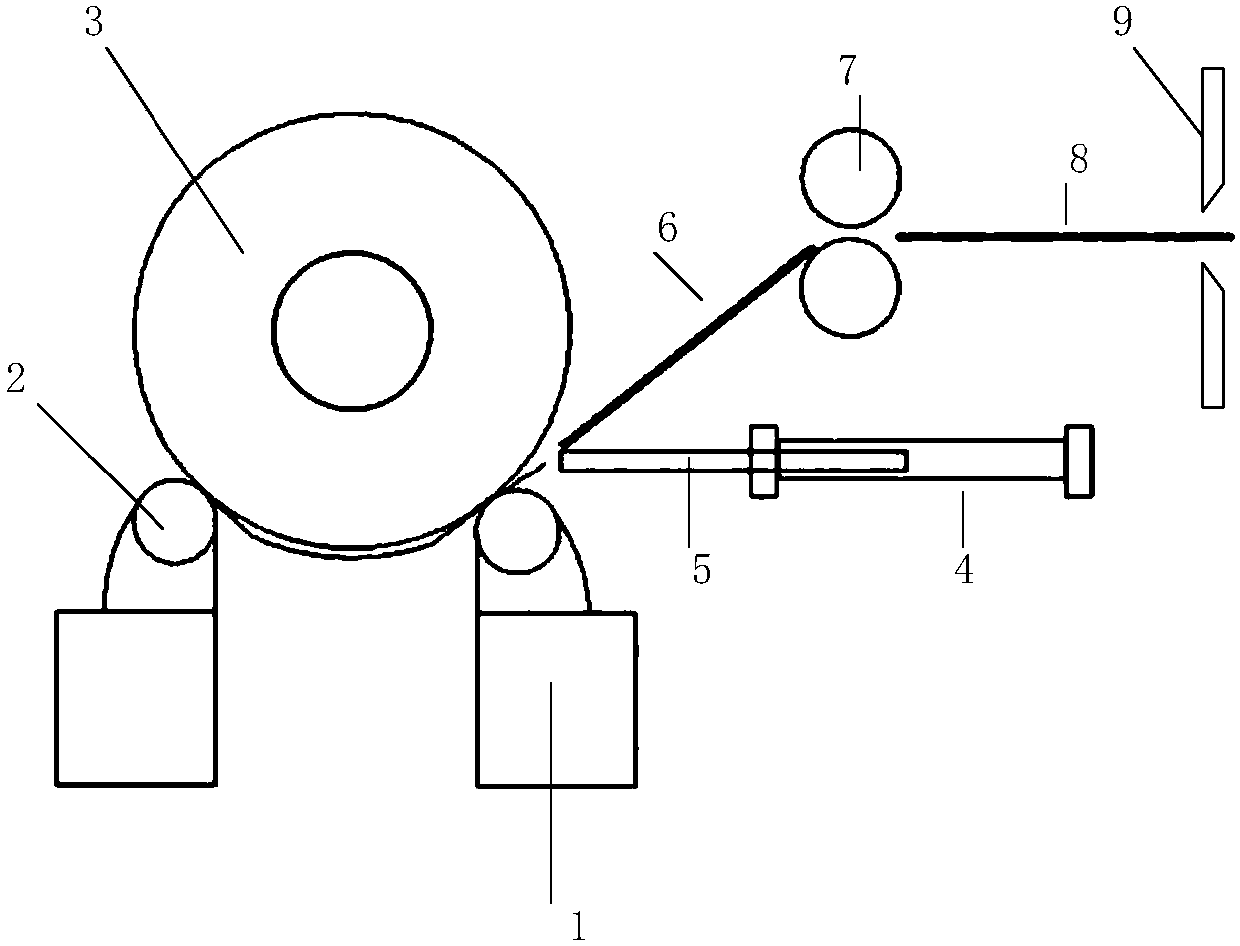

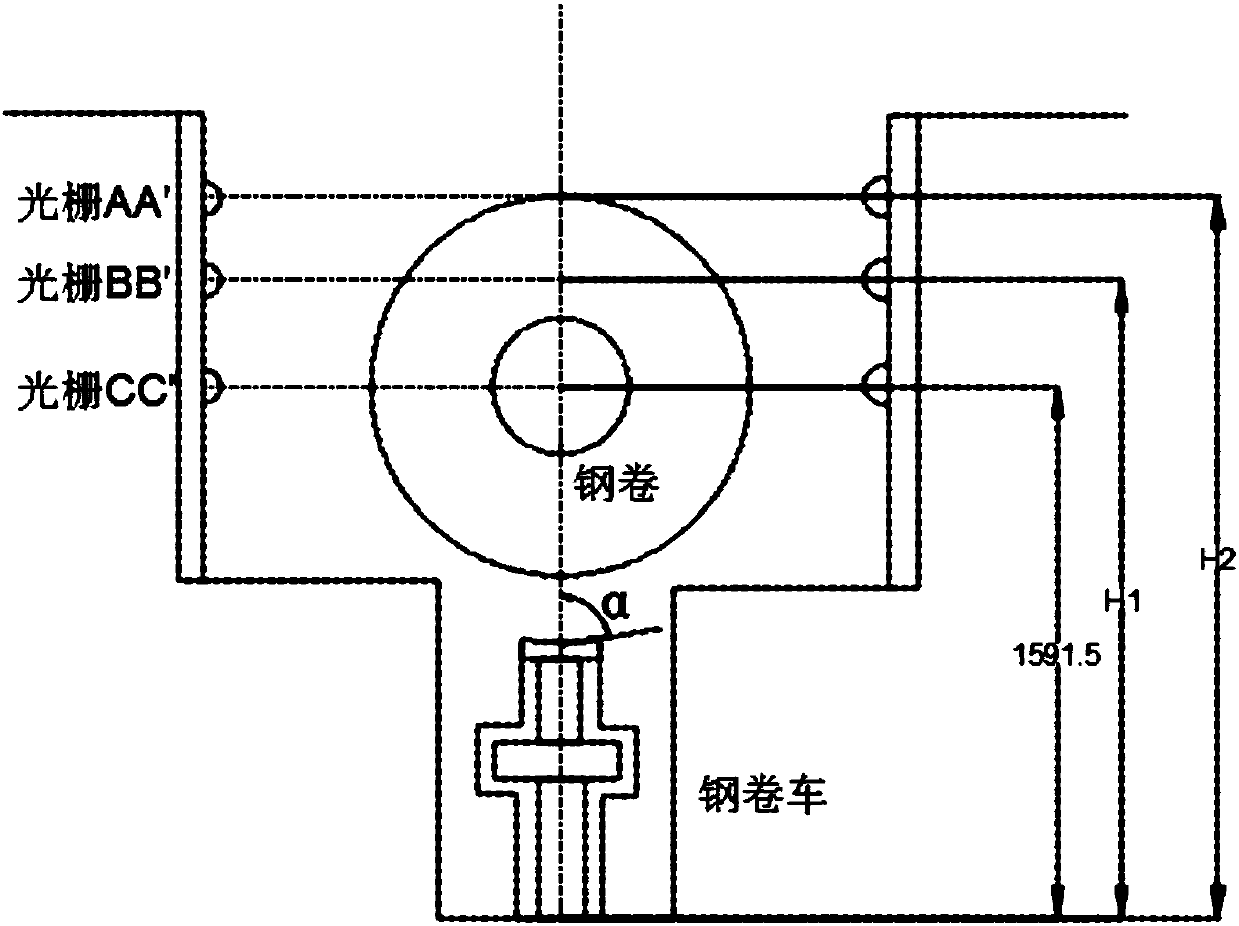

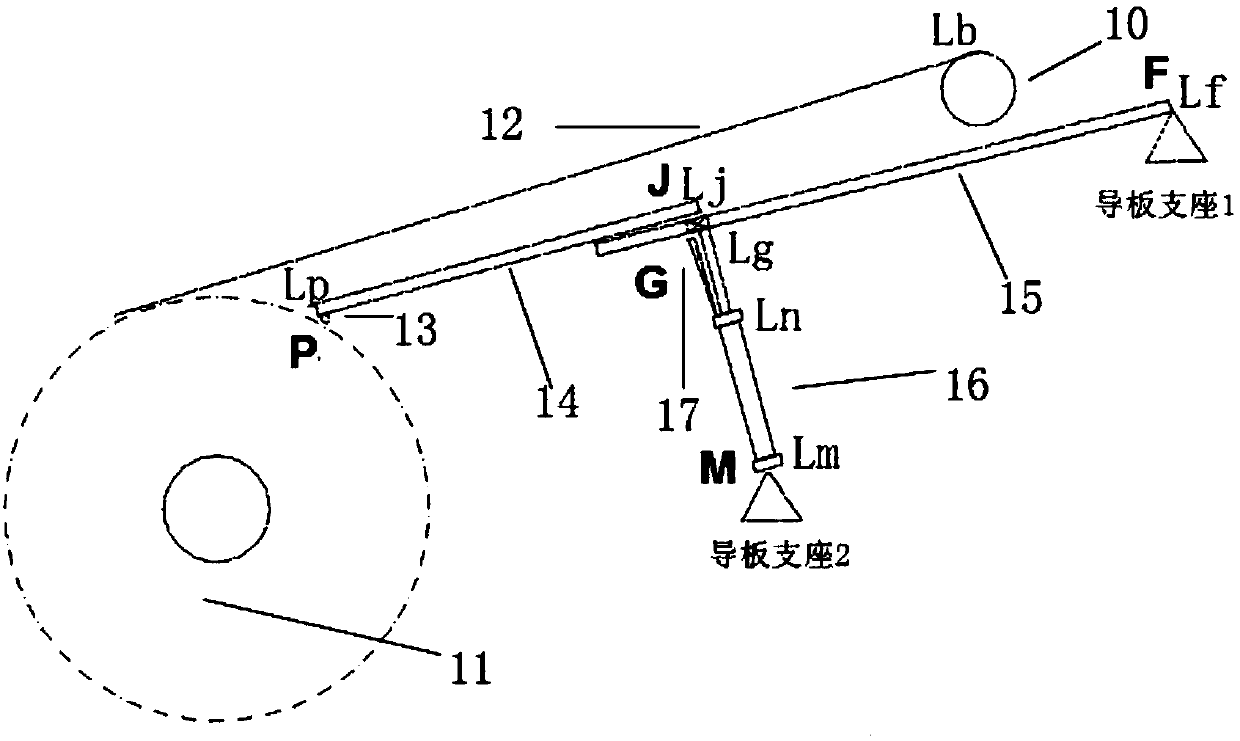

[0075] Such as figure 1 , image 3 As shown, a steel coil uncoiling automatic positioning auxiliary threading system of the present invention includes: a preparation station saddle 1, a preparation station rotating ground roller 2, a preparation station threading guide plate 1 6, a preparation station steering roller 7, a preparation station threading Guide plate two 8, preparation station slitting and cutting shears 9; at the entrance of the preparation station threading guide plate one 6, beside the rotating ground roller 2 of the preparation station, a leading positioning hydraulic cylinder 4 and a leading positioning hydraulic cylinder piston rod 5 are additionally provided. A proximity switch is provided on the piston rod 5 of the cylinder; by positioning the proximity switch on the piston rod 5 of the hydraulic cylinder, the control system can automatically adjust the position of the coil head to the five o'clock direction at the preparation station, solving the problem ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap