An integrated tooling for line drawing and positioning and its application method

A tooling and positioning pin technology, which is applied in positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to ensure uniform wall thickness distribution, uneven distribution of blanks, and inability to highly match, and achieves simple and easy processing. The effect of processing quality and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The processing method is described in further detail below. The specific parts processing steps are as follows:

[0024] The invention provides an integrated tooling for line drawing and positioning, including a positioning box, a clamping table and a processing base;

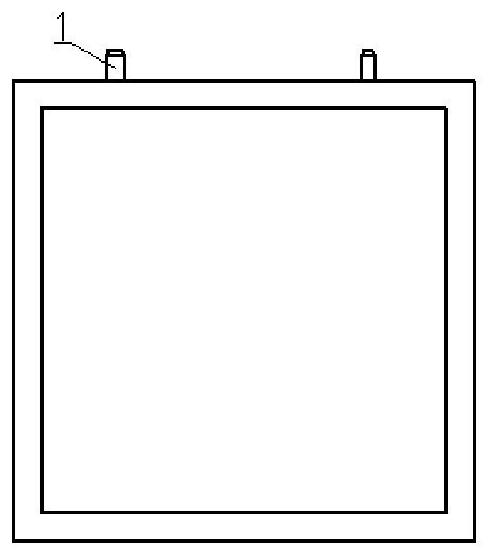

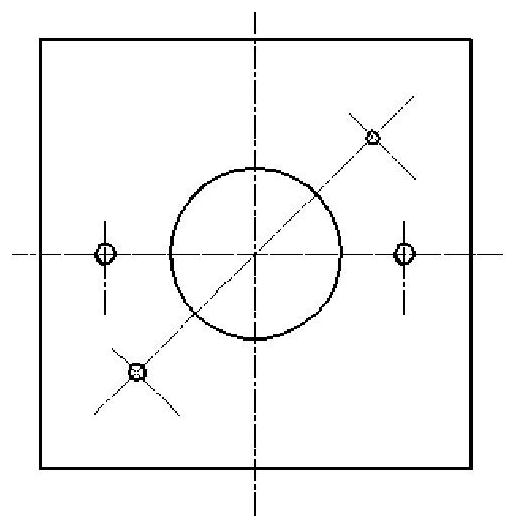

[0025] The square box has a cubic shape, with threaded holes on the upper end of the cube and positioning pins; the three-dimensional coordinate system of the square box corresponds to the machining coordinate system of the machine tool, and there is a conversion relationship;

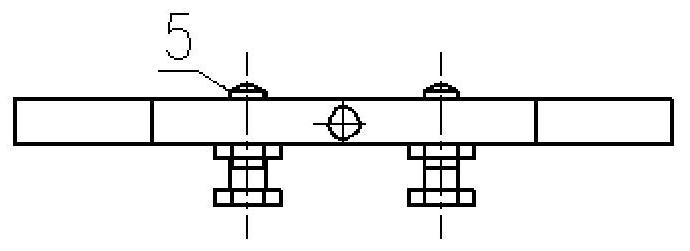

[0026] The clamping table is provided with three adjusting nails arranged in a uniform ring shape. The three adjusting nails are used to support the parts, and the spatial position of the parts can be adjusted by the three adjusting nails; a pressure plate is also provided on the clamping table, so The pressure plate is used to press and fix the parts on the three adjusting nails; the clamping table is provided with positioning holes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com