Preparation method of seal

A technology for stamps and stamping blanks, which is applied in the field of stamp preparation, can solve the problems of scarcity of stamping stone resources and insufficient refinement of traditional ceramics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail through the drawings and examples below, but it is not intended to limit the protection scope of the present invention.

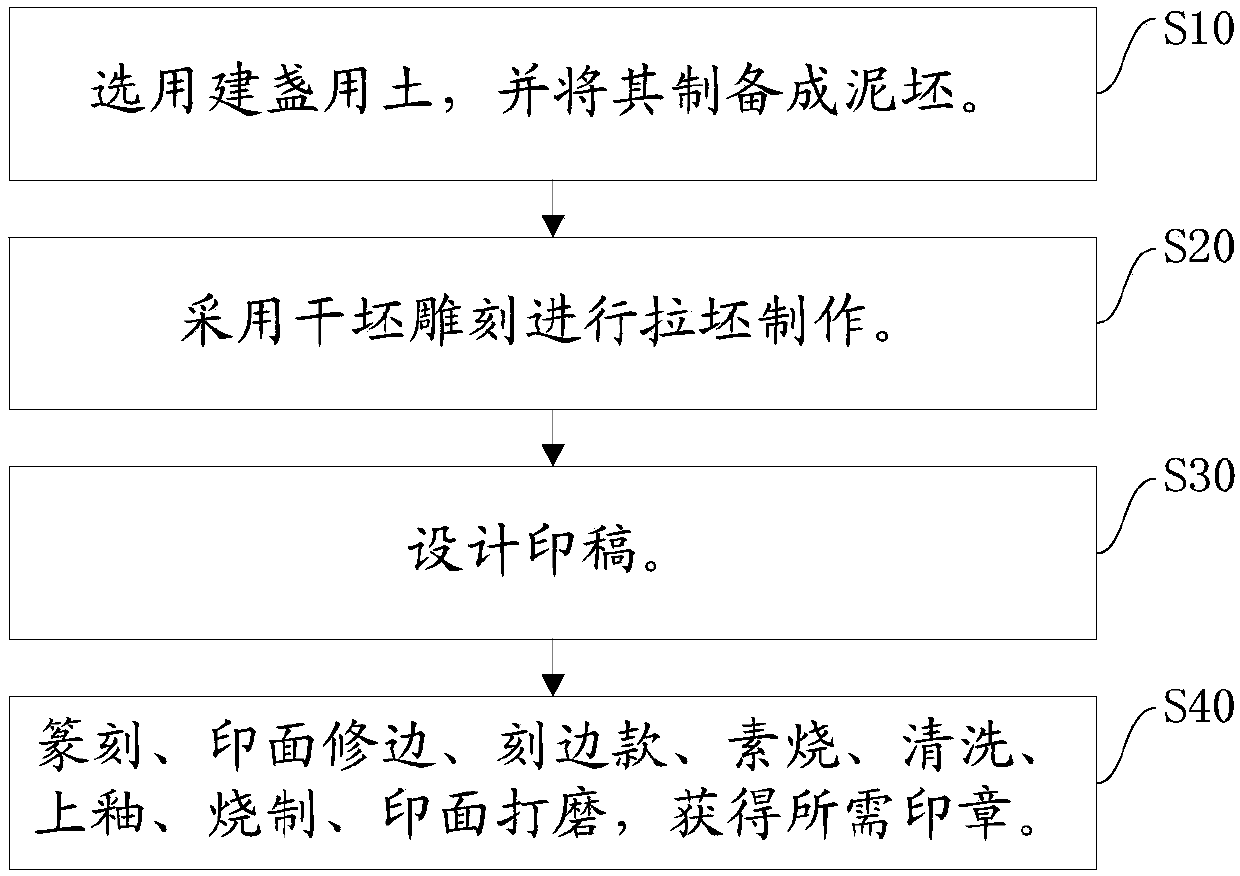

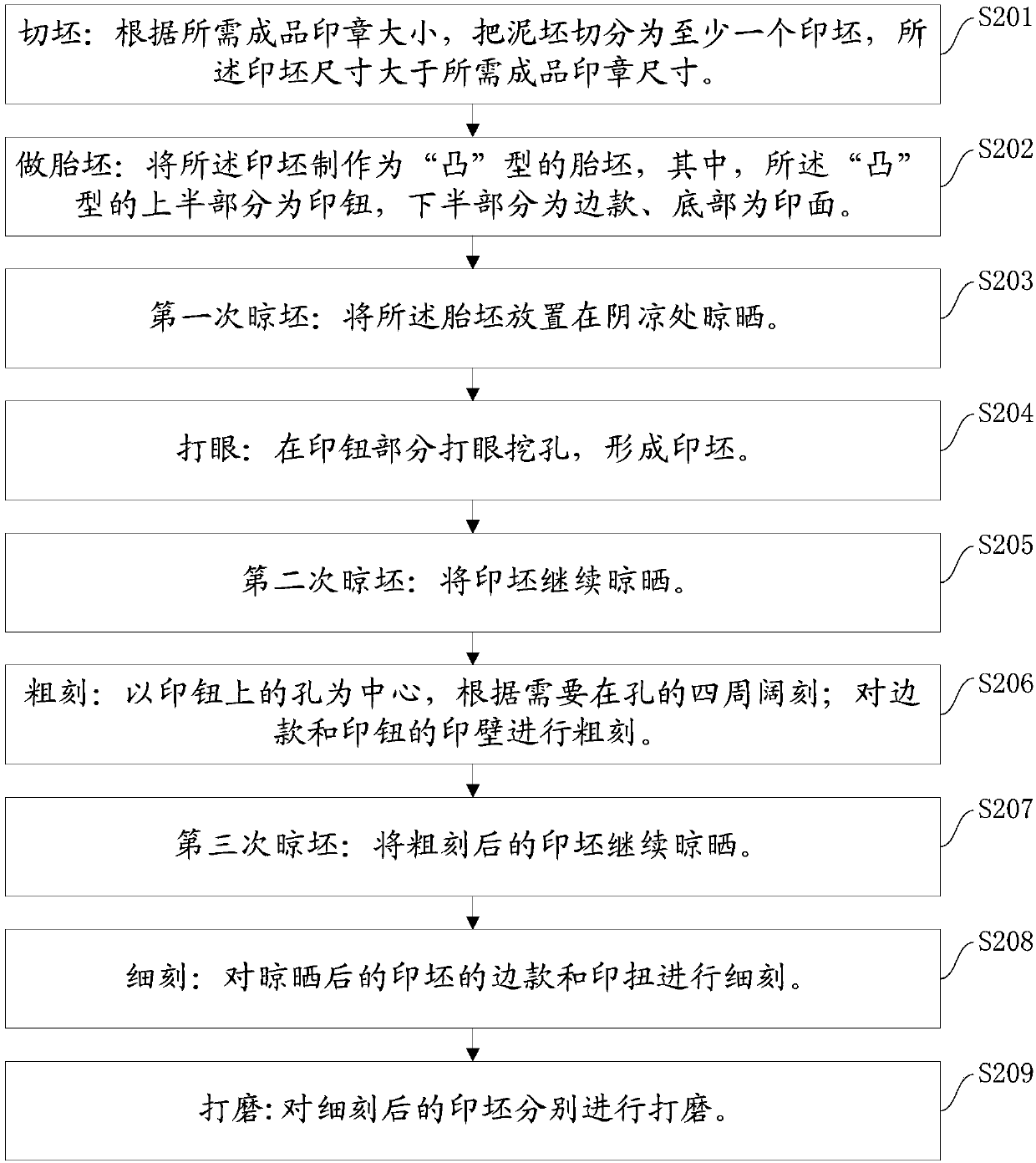

[0033] figure 1 A schematic flow chart of a method for preparing a stamp provided by an embodiment of the present invention, such as figure 1 Shown, this preparation method comprises the following steps:

[0034] Step S10, selecting soil for building a lamp, and preparing it into mud.

[0035] Material selection: select the soil for building the lamp and prepare it into mud. Specifically, it is the local soil in Jianyang area. It contains about 8% iron and is iron oxide, but its plasticity is poor, its shrinkage is large, its fire resistance is not high, it is easy to deform, crack, and foam, and its success rate is low. High, in order to solve this problem, in the process of drawing the blank, the present invention changes the traditional wet method into a method of engraving after drying,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com