Vertical heat sealing machine adjustable direction guide apparatus

A technology of guiding device and heat sealing machine, applied in the direction of lamination device, layered product, lamination, etc., can solve the problems of stretching offset and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

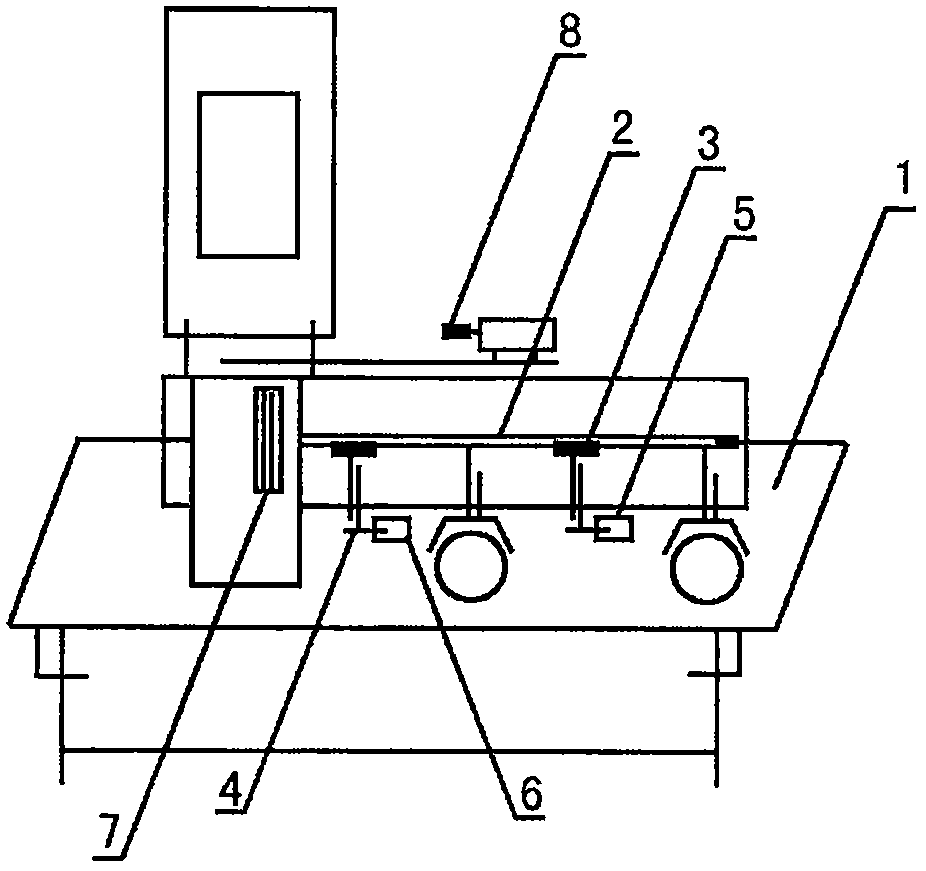

[0012] Embodiment: as shown in the accompanying drawing. The adjustable direction guide device of the vertical heat sealing machine includes a heat sealing machine body (1), and a guiding structure is set on the inner side of the beam of the body (1), including a suspended two-way slide rail device (2), a width adjustment device (3), a lifting type The column (4), the No. 1 front stretching clamping plate (5), the No. 2 rear alignment plate (6), and the levelness monitoring device (7) are located on the left side of the beam, and can be used according to the heat sealing method required by the material. Adjustable clamping guidance for the front and side to avoid offsetting the horizontal orientation.

[0013] The adjustable direction guide device of the vertical heat sealing machine is equipped with a prompting device (8), and a corresponding prompt is issued when a horizontal position deviation occurs.

[0014] The vertical heat sealing machine has an adjustable direction g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com