Automatic bowl filling machine and bowl filling method thereof

A pot-filling and automatic technology, which is applied in the directions of packaging, transportation and packaging, and the types of packaging items, can solve the problems of large space occupation, difficult debugging, complicated equipment structure, etc., and achieves simple and compact structure, high pot-filling efficiency, and operation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

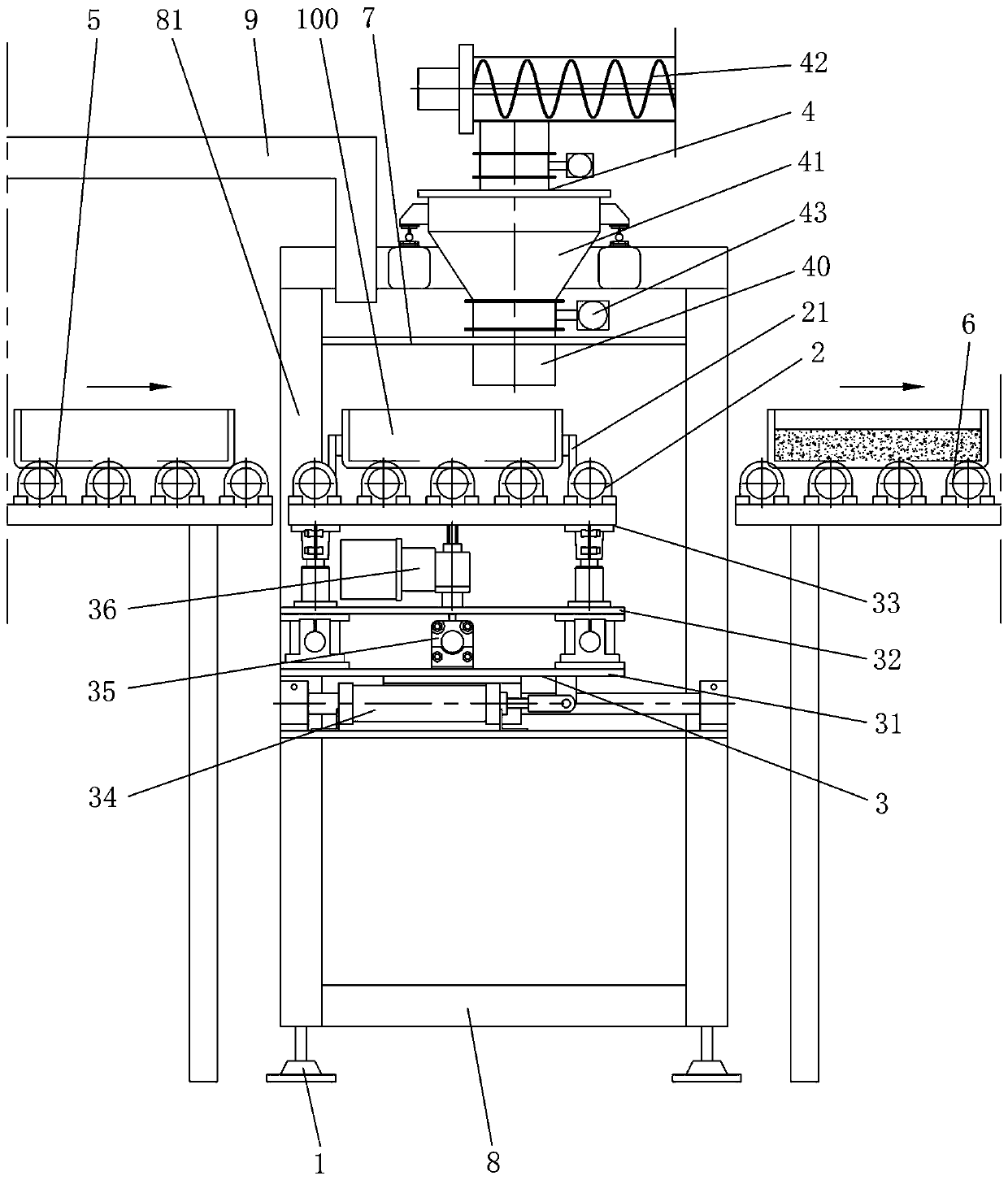

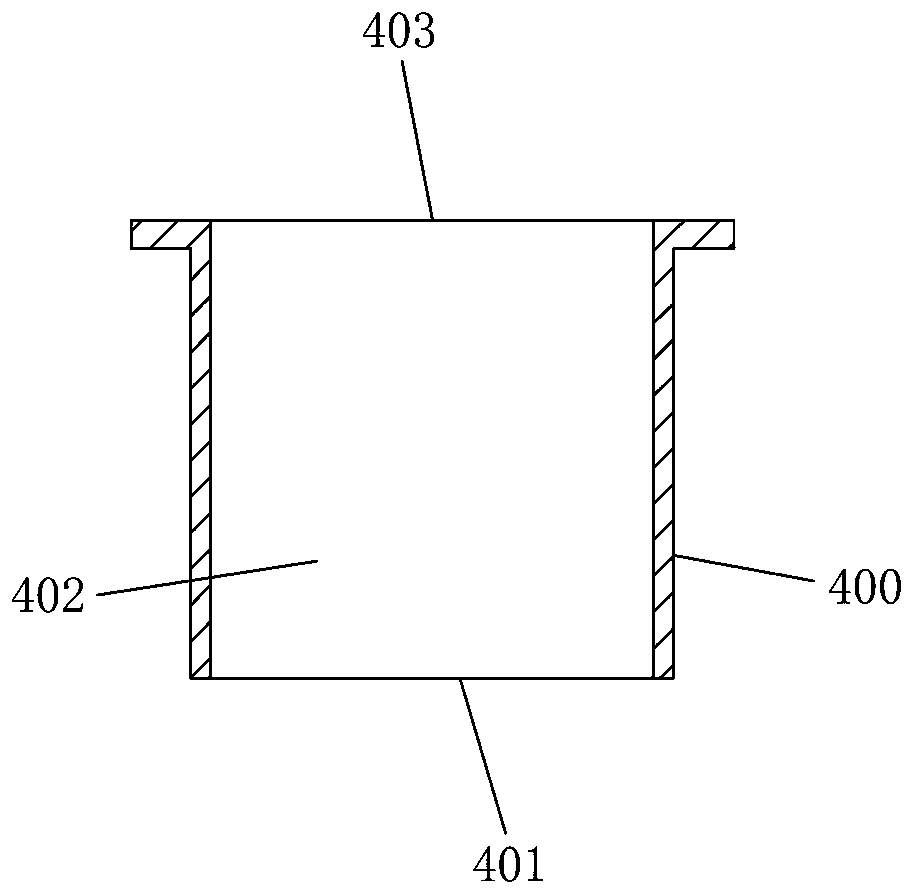

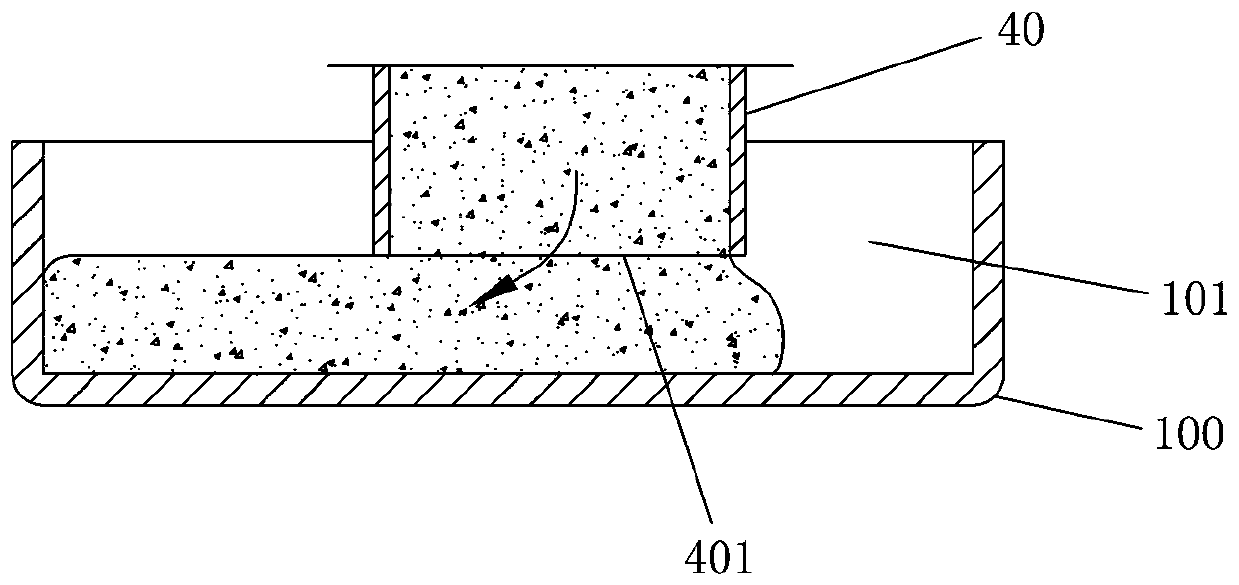

[0032] Such as Figure 1 to Figure 3 As shown, the automatic bowl loading machine of this embodiment includes a frame 1 and a loading conveyor line 2 for carrying and transporting the sagger 100, and the loading conveyor line 2 is provided with a fixing device that can loosen or fix the sagger 100 21. The loading conveying line 2 is installed on the frame 1 through a three-dimensional space displacement driving device 3. The three-dimensional spatial displacement driving device 3 can drive the horizontal and vertical translational movement of the charging conveying line 2. The machine above the charging conveying line 2 The frame 1 is equipped with a blanking device 4 that relies on the self-weight of the material for blanking. The blanking device 4 has a blanking head 40 that can be inserted into the sagger 100. The lower end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com