Small-size nonel tube detonator production line

A detonator and production line technology, applied in the direction of detonators, offensive equipment, etc., can solve the problems of large placement space, unfavorable production cost, and bulky volume, and achieve the effect of compact structure, ingenious structure, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

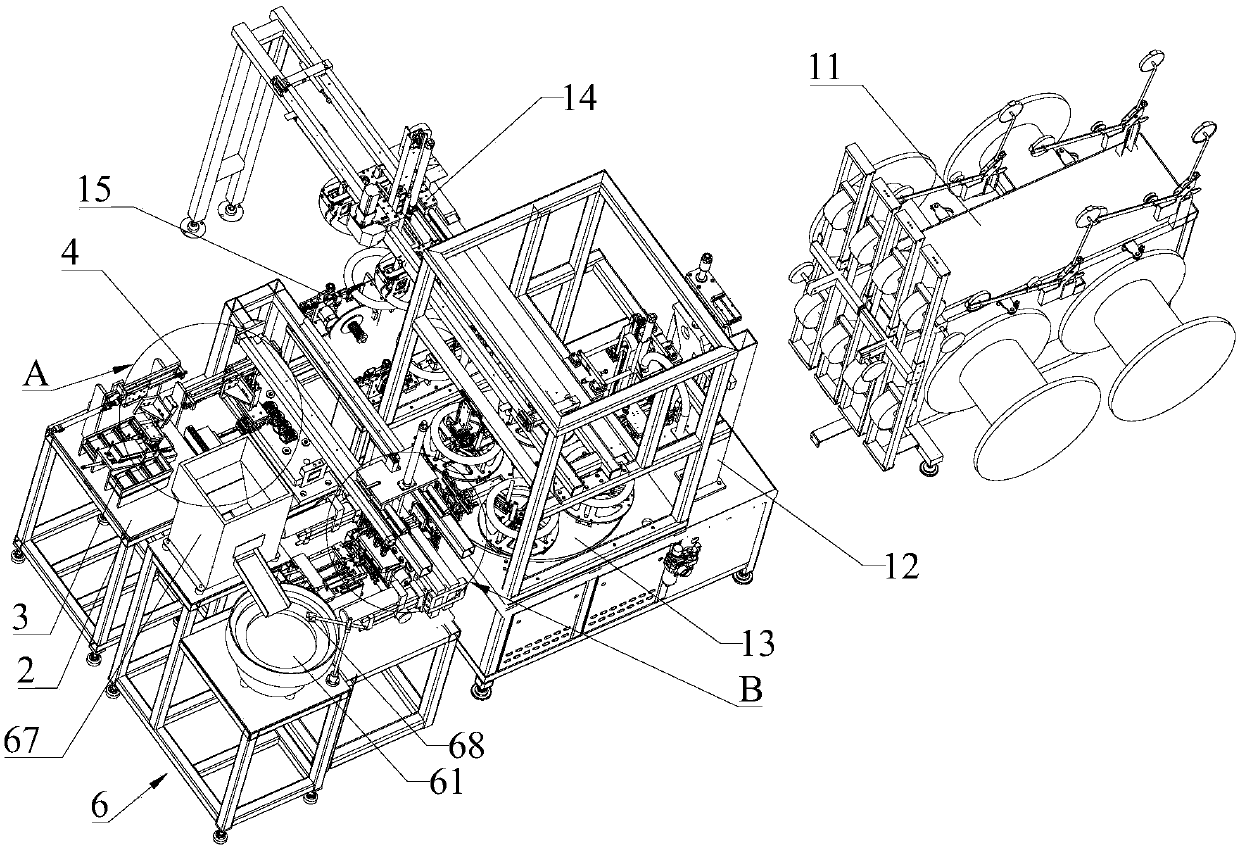

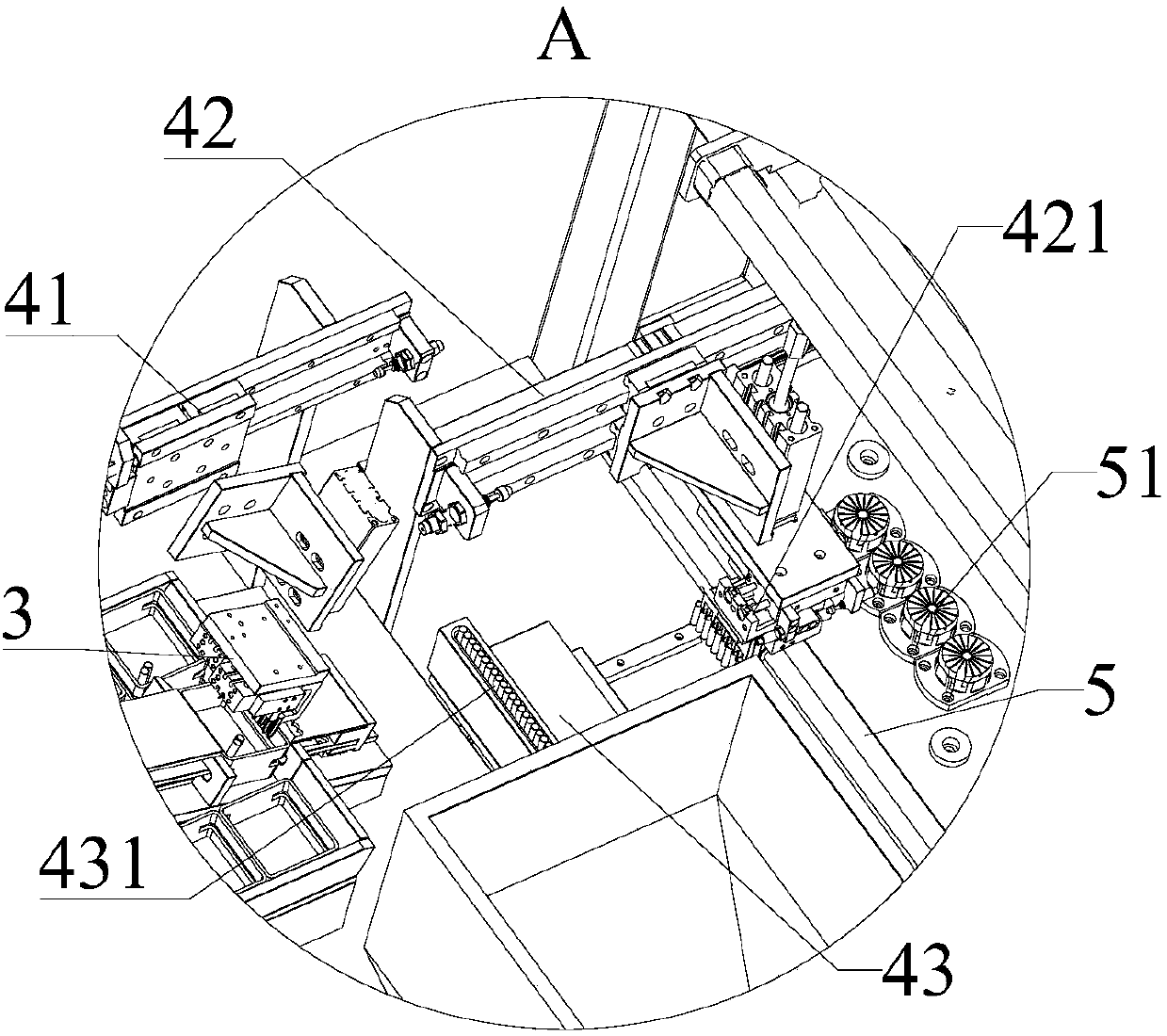

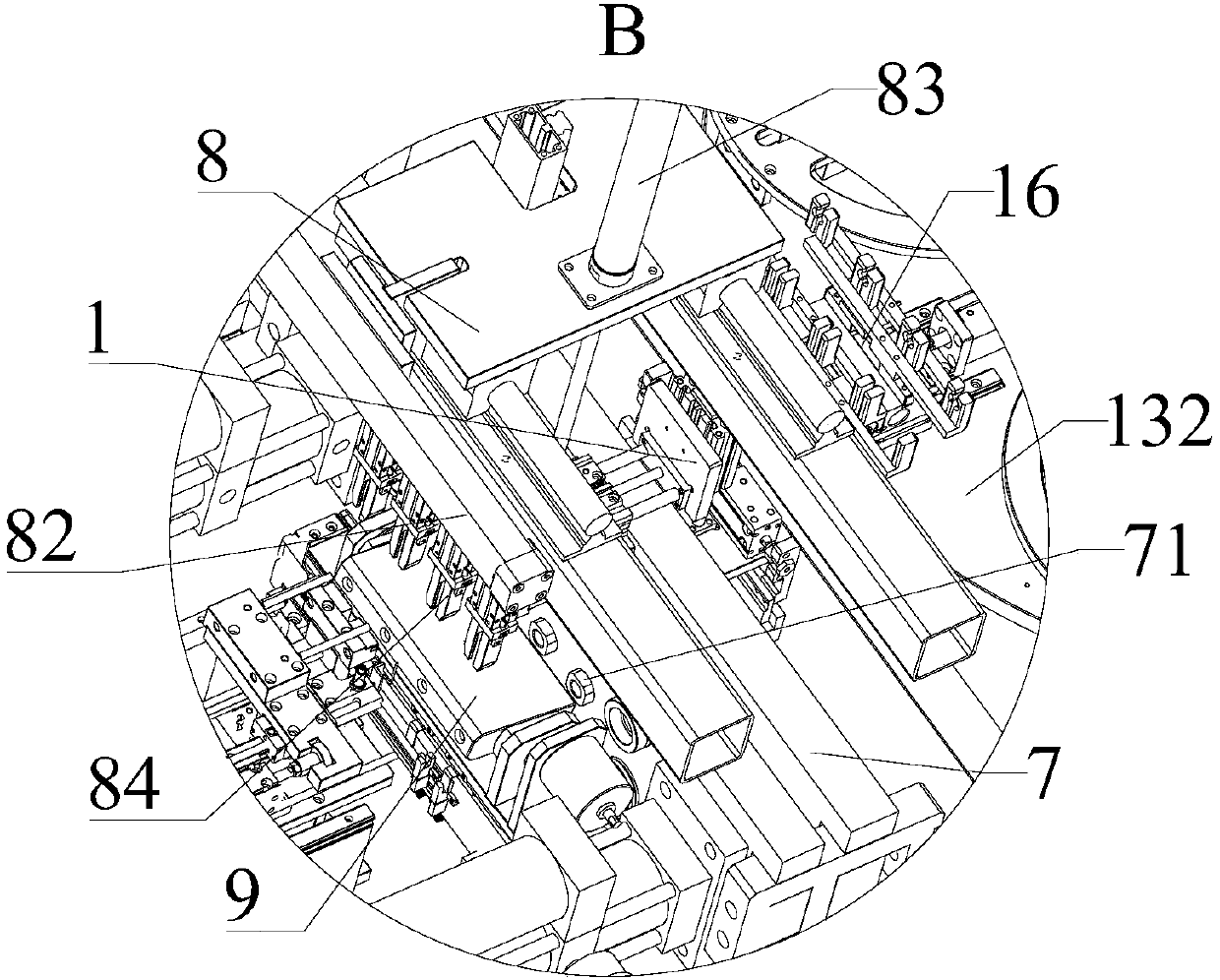

[0060] Please refer to Figures 1 to 12 , the first embodiment of the present invention is: a small nonel detonator production line, including a guide mechanism 1, a nonel processing mechanism, a frame assembly 2, and a feeding mechanism 3, a material retrieving mechanism respectively arranged on the frame assembly 2 The mechanism 4, the waist mechanism 5, the rubber plug assembly mechanism 6 and the bayonet mechanism 7 also include the first retrieving assembly 8 and the transition mechanism 9 arranged on the frame assembly 2; On one side, the waist clamp mechanism 5 includes a first clamp 51, the opening of the first clamp 51 is arranged along the Z-axis direction; 5; the transition mechanism 9 is located on one side of the waist mechanism 5, and the first pick-up assembly 8 is slidably arranged between the waist mechanism 5 and the transition mechanism 9, and the transition mechanism 9 includes a first rotary drive member 91 And the transition block 92 that is provided wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap