EGR cooler of integrated water-removing device

An EGR cooler and water collection technology, applied in the direction of charging system, machine/engine, engine components, etc., can solve the problems of weak automation and poor drainage effect, and achieve strong automation, high degree of automation, and drainage effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

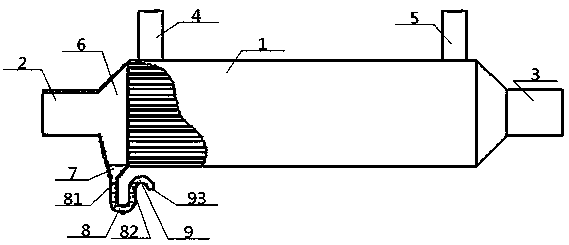

[0036] see Figure 1 to Figure 3 , an EGR cooler with an integrated water removal device, comprising a body 1, an air inlet pipe 2, an air outlet pipe 3, a liquid inlet pipe 4 and a liquid outlet pipe 5, the air inlet pipe 2 communicates with the air outlet pipe 3 through the body 1, The side of the device body 1 communicates with the liquid inlet pipe 4 and the liquid outlet pipe 5; A water collecting funnel 7 with a wide upper part and a narrower lower part is provided at the position, the top of the water collecting funnel 7 communicates with the bottom of the hollow cavity 6, the bottom of the water collecting funnel 7 communicates with the left top port 81 of the U-shaped pipe 8, and the U-shaped The right top port 82 of the pipe 8 communicates with the water outlet 9 , and the left top port 81 and the right top port 82 are both located at the highest point of the U-shaped pipe 8 . Preferably, the top of the water collecting funnel 7 is flush with the bottom of the body ...

Embodiment 2

[0039] Basic content is the same as embodiment 1, the difference is:

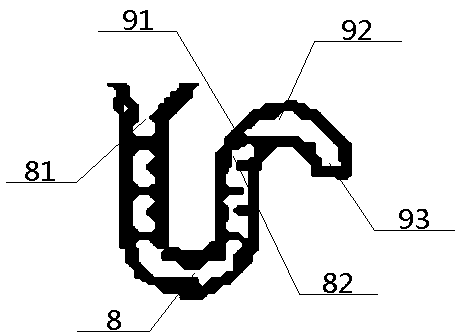

[0040] The water outlet part 9 includes a left bottom port 91, a middle arc portion 92 and a right bottom port 93. The right top port 82 communicates with the right bottom port 93 after passing through the left bottom port 91 and the middle arc portion 92 in turn, and the left bottom port 91 , the right bottom port 93 are all lower than the central arc portion 92 settings.

Embodiment 3

[0042] Basic content is the same as embodiment 1, the difference is:

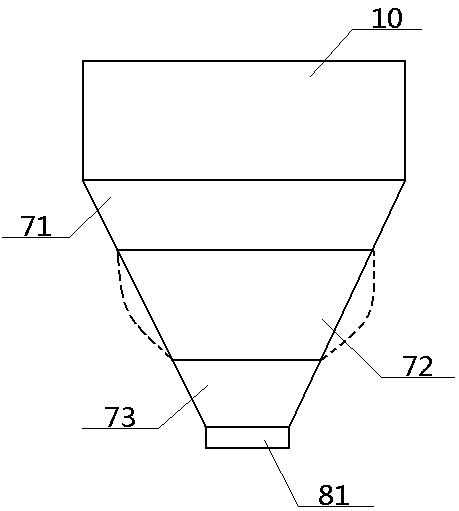

[0043] The above-mentioned water collecting funnel 7 includes an upper cone 71, a middle cone 72 and a lower cone 73, and the upper cone 71, the middle cone 72, and the lower cone 73 are all truncated conical structures with a wide top and a narrow bottom; The top of portion 71 communicates with the bottom of hollow cavity 6, and the bottom of upper cone portion 71 communicates with left top port 81 after passing through middle cone portion 72 and lower cone portion 73 successively. The manufacturing material of middle cone portion 72 is an elastic film, and The thickness of the middle taper portion 72 is greater than the thickness of the upper taper portion 71 and the lower taper portion 73 . Preferably, the top of the water collecting funnel 7 is connected to the bottom of the hollow cavity 6 through a transition part 10, the transition part 10 is a cylindrical structure, and the material of the transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com