Magnetic levitation compressor structure

A compressor and magnetic levitation technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of complex processing technology, axial displacement of shaft sleeves, increased material costs, etc., and achieve simple and compact structure. Good effect, the effect of reducing processing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

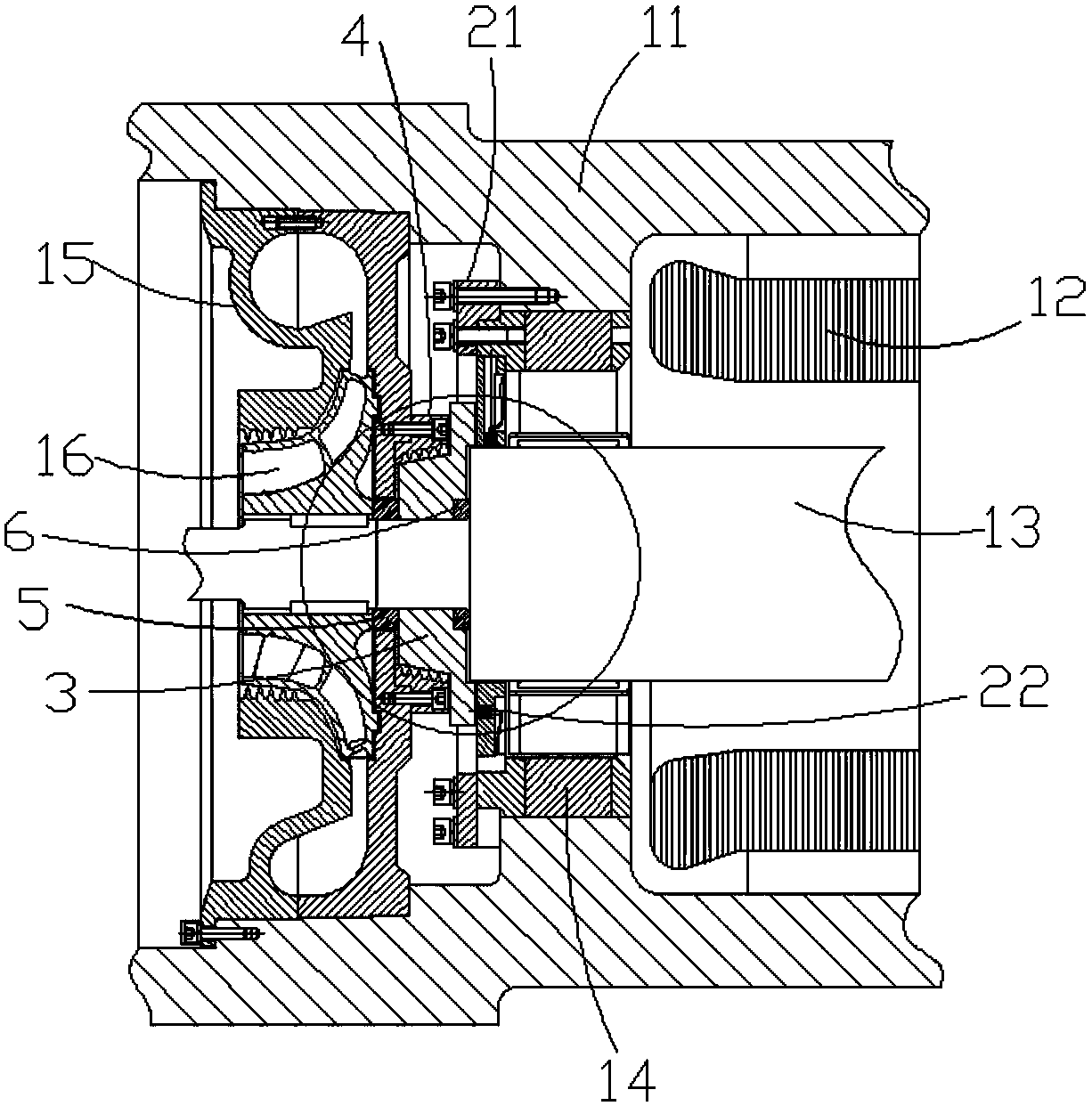

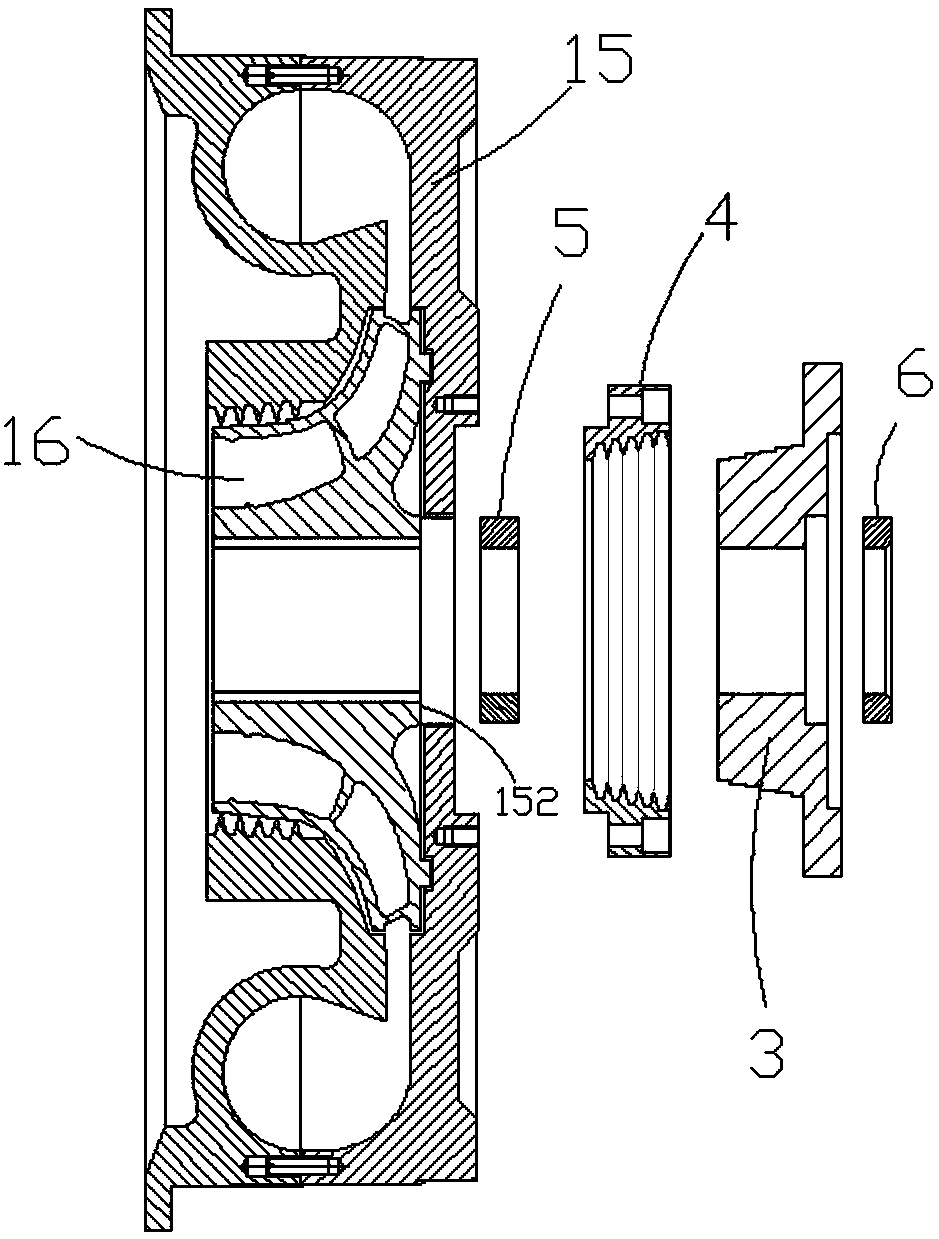

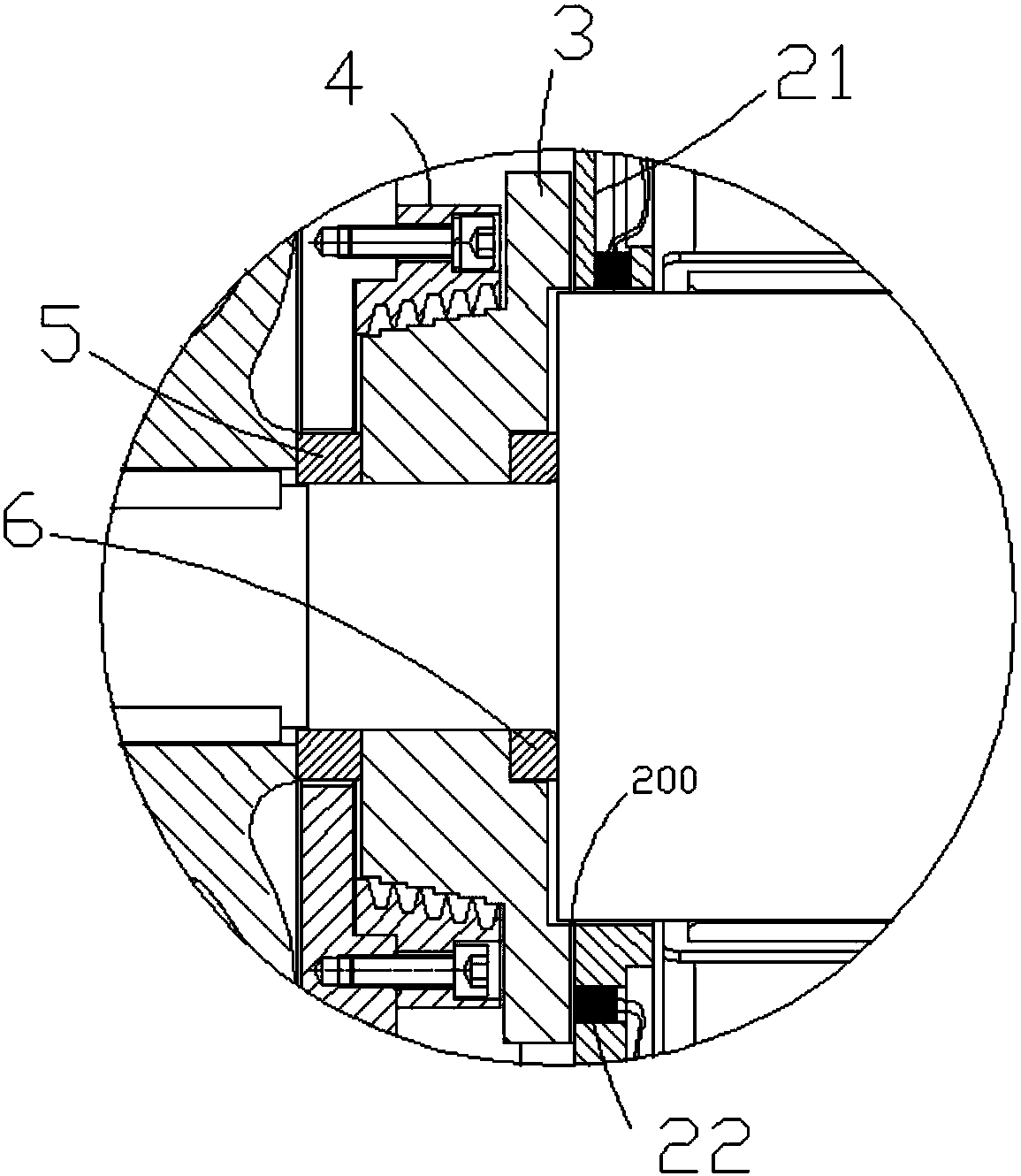

[0018] Such as Figure 1 to Figure 4 , the present invention discloses a magnetic levitation compressor structure, including a casing 11, a stator 12, a rotor 13, a magnetic bearing 14, a volute 15, an impeller 16, a sensor bracket 21 and an axial displacement sensor 22, and the stator 12 is fixed to the casing 11 Inside, the rotor 13 is installed in the stator 12, and the rotor 13 is rotatably supported in the casing 11 through the magnetic bearing 14, the sensor bracket 21 is fixed on the magnetic bearing 14, the axial displacement sensor 22 is arranged on the sensor bracket 21, and the impeller 16 It is fixedly connected with the rotor 13 , the volute 15 is fixed on the casing 11 , and the impeller 16 is arranged in the volute 15 . It also includes a balance disc 3, a seal ring 4, an impeller gap adjustment ring 5 and an axial gap adjustment ring 6, the balance dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com