Axial flow fan capable of achieving accurate zero clearance

An axial flow fan and clearance technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as deformation, aggravating the overall performance of the fan, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

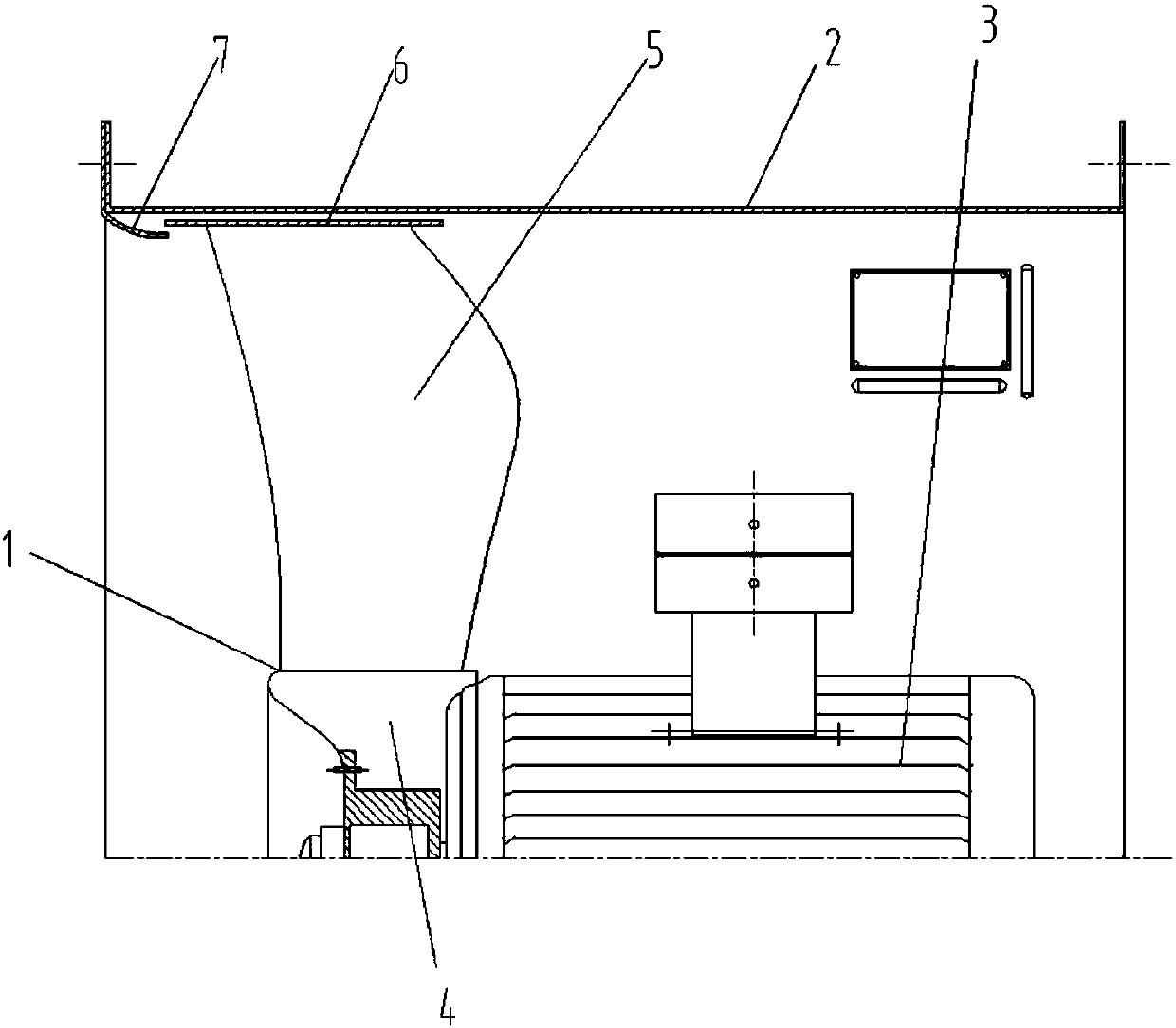

[0010] Embodiment one: if figure 1 As shown, the present invention discloses a quasi-zero-gap axial flow fan, including an impeller 1, an air cylinder 2 and a motor 3, and the impeller 1 includes a hub 4 connected to the output shaft of the motor 3 and evenly distributed on the periphery of the hub 4 Several blades 5 on the surface, as mentioned above, are basically consistent with the structure of the existing common axial flow fan. The tip partition 6 is cylindrical, and its thickness matches the width of the blade 5, that is, the projected width of the blade 5 in the axial direction of the impeller 1 is approximately the same, and the cylindrical outer wall of the wing tip partition 6 is consistent with the inner wall 2 of the air duct. are parallel to each other, and the gap is usually 5-10 mm; the flange of the air inlet of the air duct 2 is provided with a collector 7, the collector 7 is bell-shaped, and its small head is facing the wingtip partition 6, so Described win...

Embodiment 2

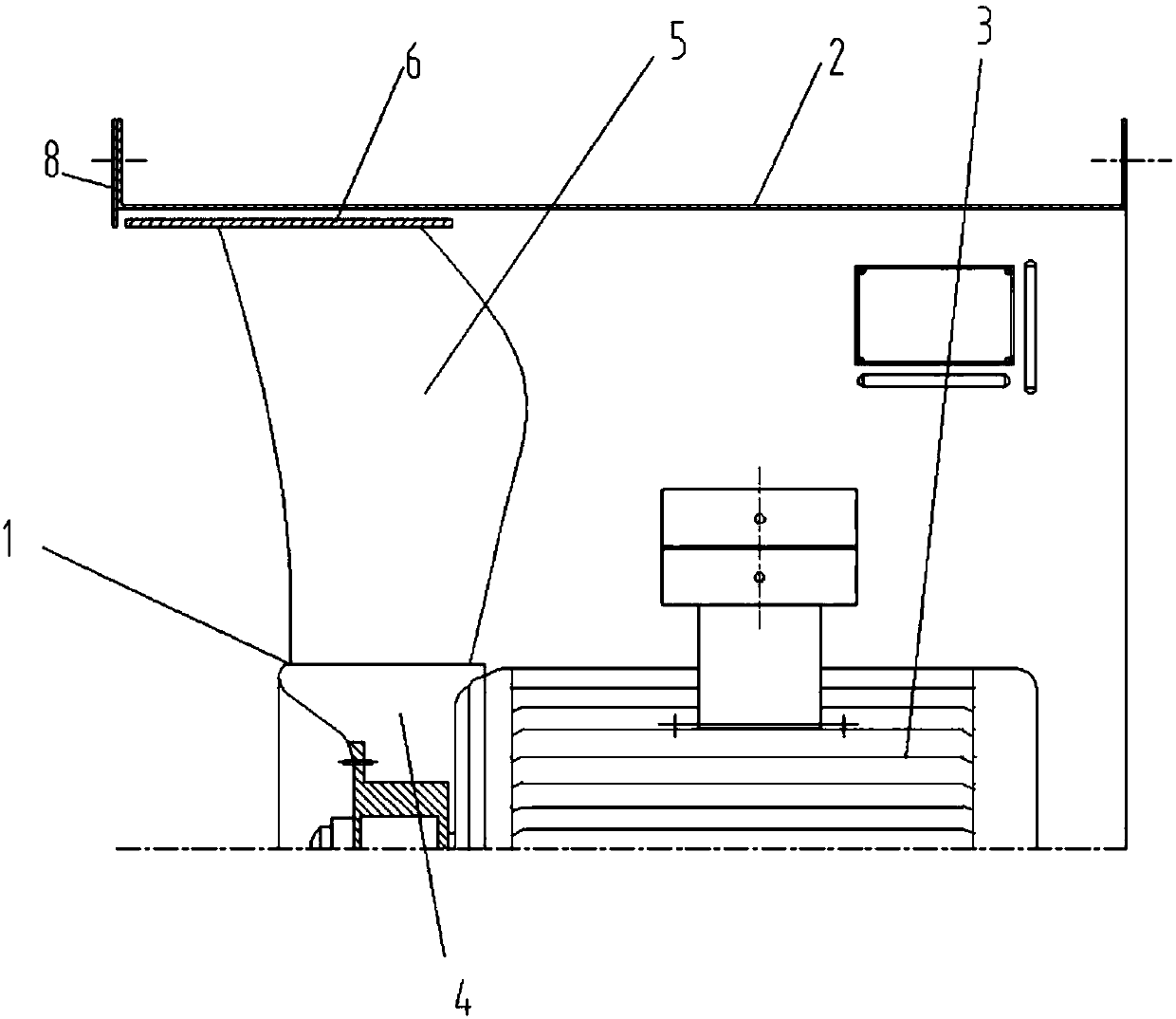

[0011] Embodiment two: if figure 2 As shown, the air inlet flange of the air cylinder 2 is provided with an inlet baffle 8 to replace the collector 7, and the inlet baffle 8 is fixed on the flange of the air cylinder 2 and extends toward the center of the air cylinder 2. , the end of the wingtip partition 6 towards the air inlet is level with the inner end of the inlet partition 8, and the gap between the wingtip partition 6 and the inlet partition 8 is 2-5 mm. Since the manufacture and installation of the inlet partition 8 is more convenient, the cost is lower, and the effect similar to that of the current collector 7 can be achieved, so it is more widely used in actual production occasions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com