Thin-wall double-eccentric-part spherical shell structure provided with rigid shaft

A spherical shell structure, rigid shaft technology, applied in the cocks, engine components, mechanical equipment and other directions including cut-off devices, can solve the problems of valve seat and ball wear, increase the weight of the engine, reduce the reliability of the engine, etc., and reduce the weight. , The effect of simplifying the composition of the engine system and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

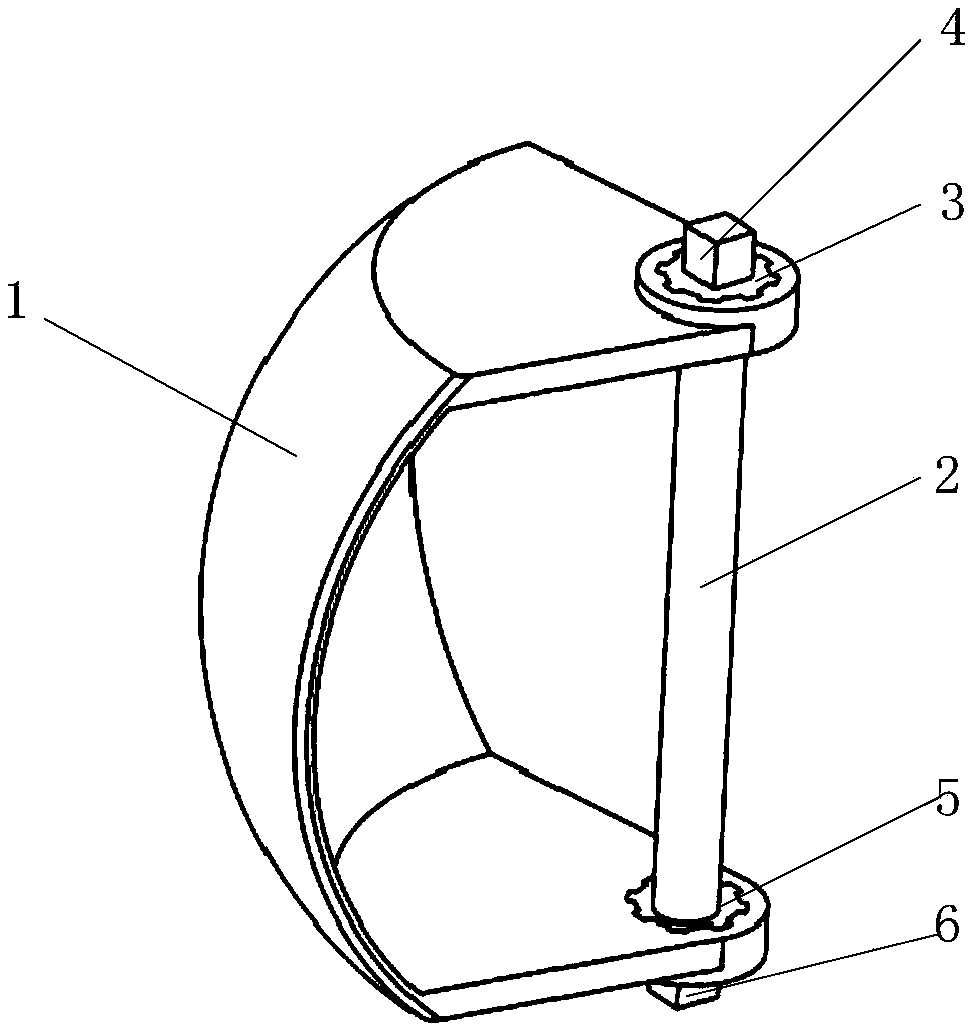

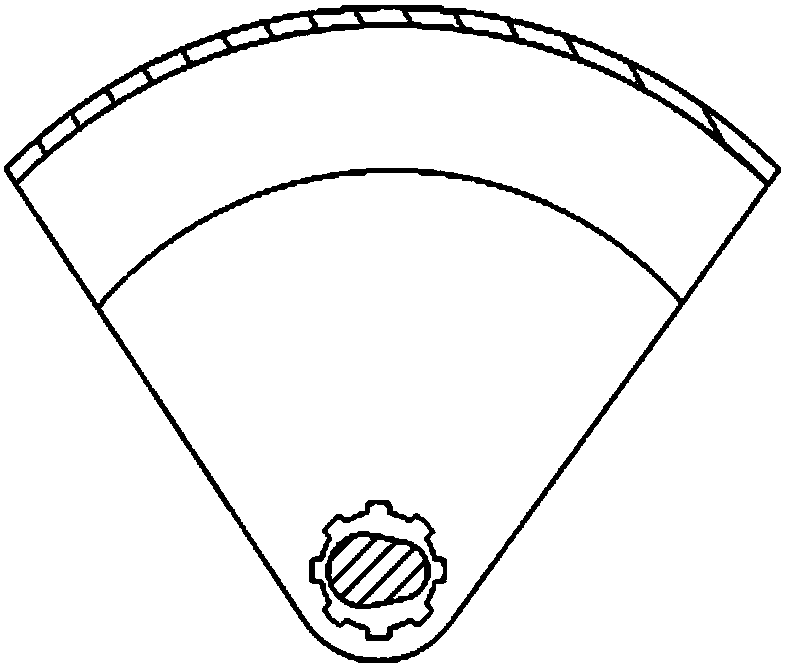

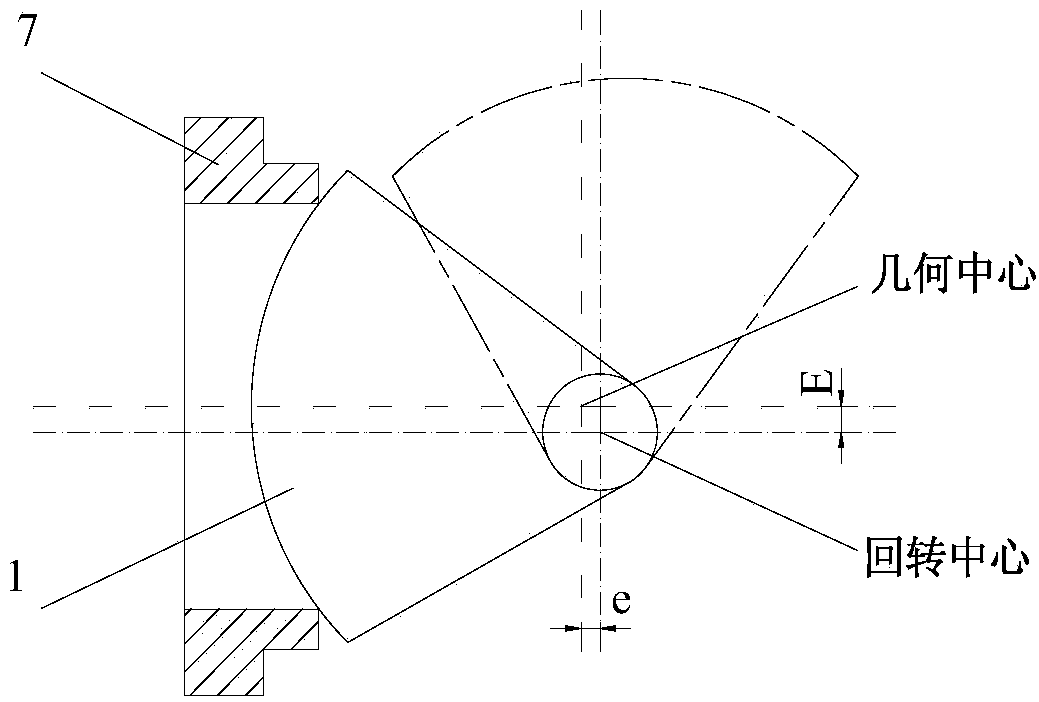

[0023] Such as figure 1 As shown, the present invention is a double eccentric thin-walled spherical shell structure with a rigid shaft. The main body shape is a 1 / 4 part of the thin-walled spherical shell 1, and the ratio of the shell thickness to the outer diameter of a large-diameter ball valve with a ball diameter > 250 mm is 1 / 40. ~1 / 50, the advantage of this design is that the circumferential and radial dimensions of the spherical shell are reduced as much as possible under the condition of ensuring the strength, and the light weight of the sphere is realized. The lower end provides radial support for the spherical shell, and the rigid shaft 2 penetrates between the upper and lower end faces, which is connected with the spherical shell 1 through the upper spline 3 and the lower spline 5, so as to realize the overall rotation of the thin-walled spher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com