Steel structure anchor block formed through connection of box iron and water supply and return fixed joints and box iron calculation method

A technology for fixed joints, water supply and return, applied in calculation, design optimization/simulation, pipes/pipe joints/fittings, etc., can solve problems such as volume reduction, size does not meet the requirements, and concrete cannot reach the curing period, etc., to achieve Ensure firmness and stability, improve construction efficiency, and improve overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

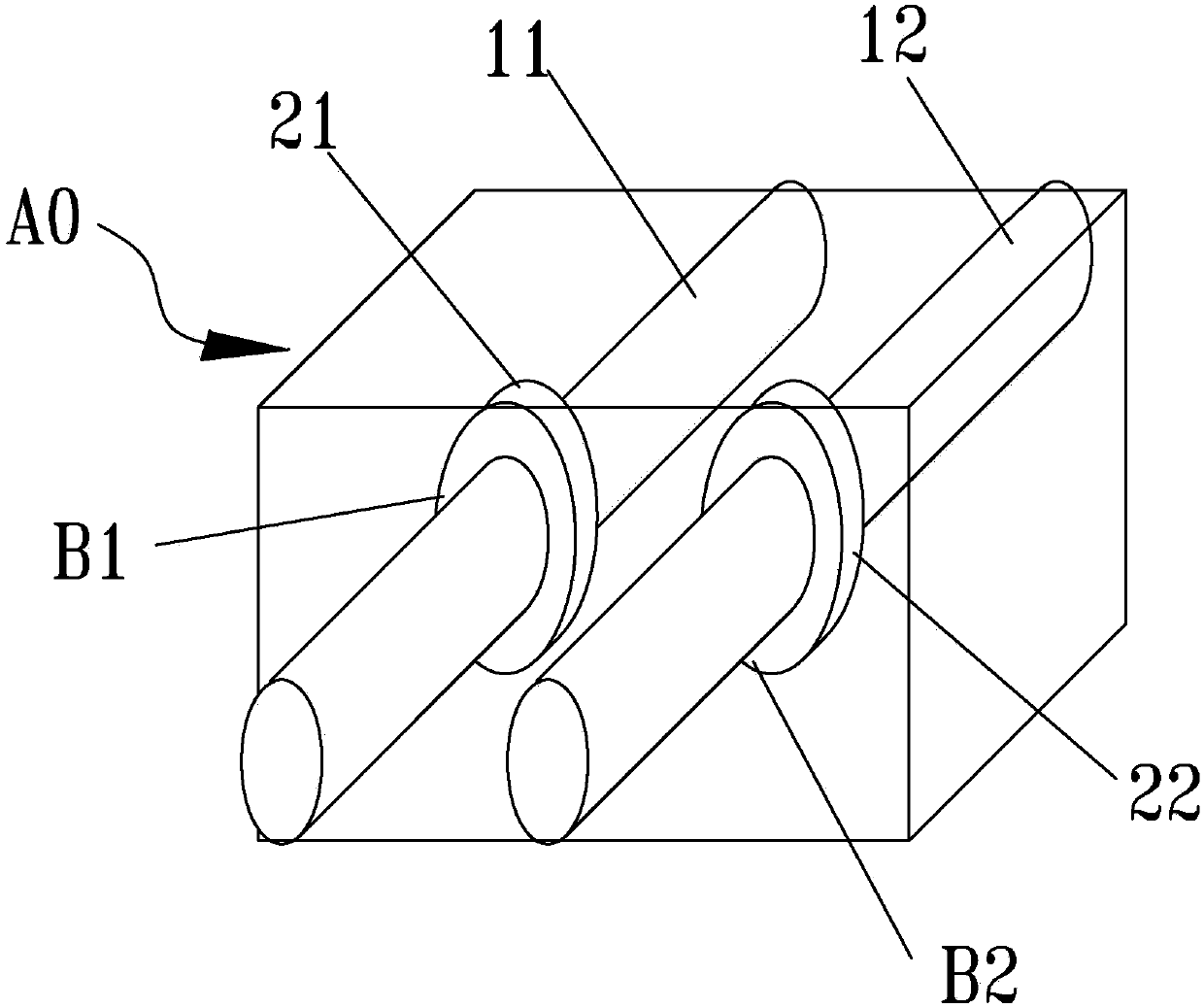

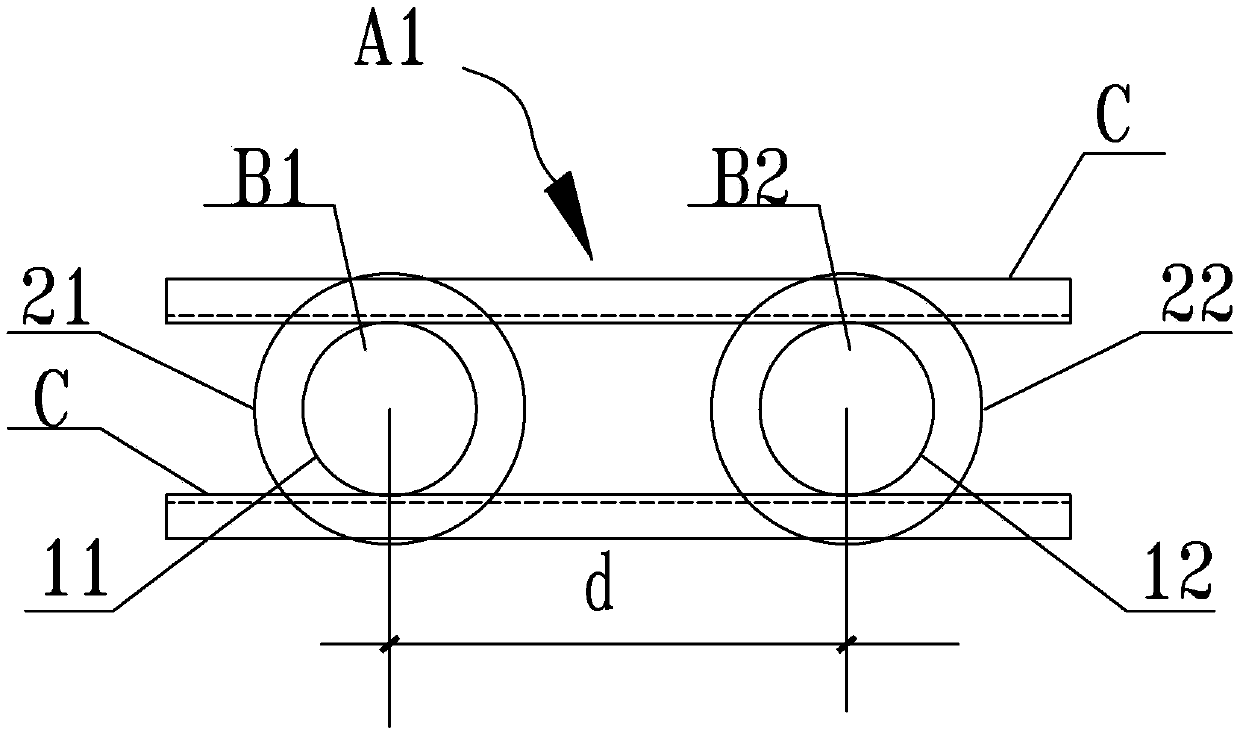

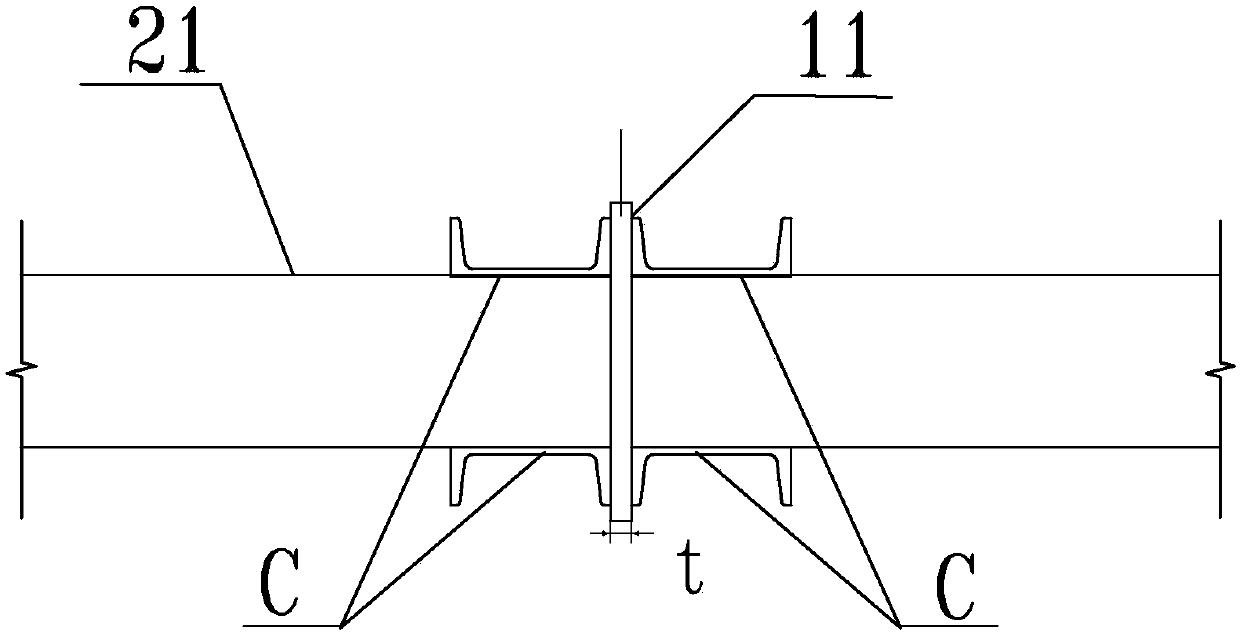

[0066] Figure 2-3 A steel structure fixed pier A1 with a channel steel connecting water supply and return water fixed joints is shown. It includes two fixed water supply and return joints B1 and B2 arranged in parallel. The water supply connection pipe 11 and the return water connection pipe 12 of the return water ring plates 21, 22 are characterized in that the supply and return water fixed joints B1, B2 pass along the edges of the supply and return water ring plates 21, 22 The four channel steels C welded to the top and bottom of the water supply and return connection pipes on both sides of the pipeline are fixedly connected together; each channel steel C is attached to the side of the supply ring plate 21 or back The side of the water ring plate 22 and the bottom of the groove are placed against the body of the water supply connection pipe 11 or the return water connection pipe 12.

[0067] The present invention is also characterized in that ribs C1 fixedly connected to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com