Box-type heat pump drying cabinet

A heat pump drying and box-type technology, which is applied in drying chambers/containers, drying gas arrangement, local agitation dryers, etc., can solve the problems of inability to detect the drying box in real time, high energy consumption, fire, etc., and improve air utilization efficiency and drying effect, reducing energy loss, and extending the elapsed time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

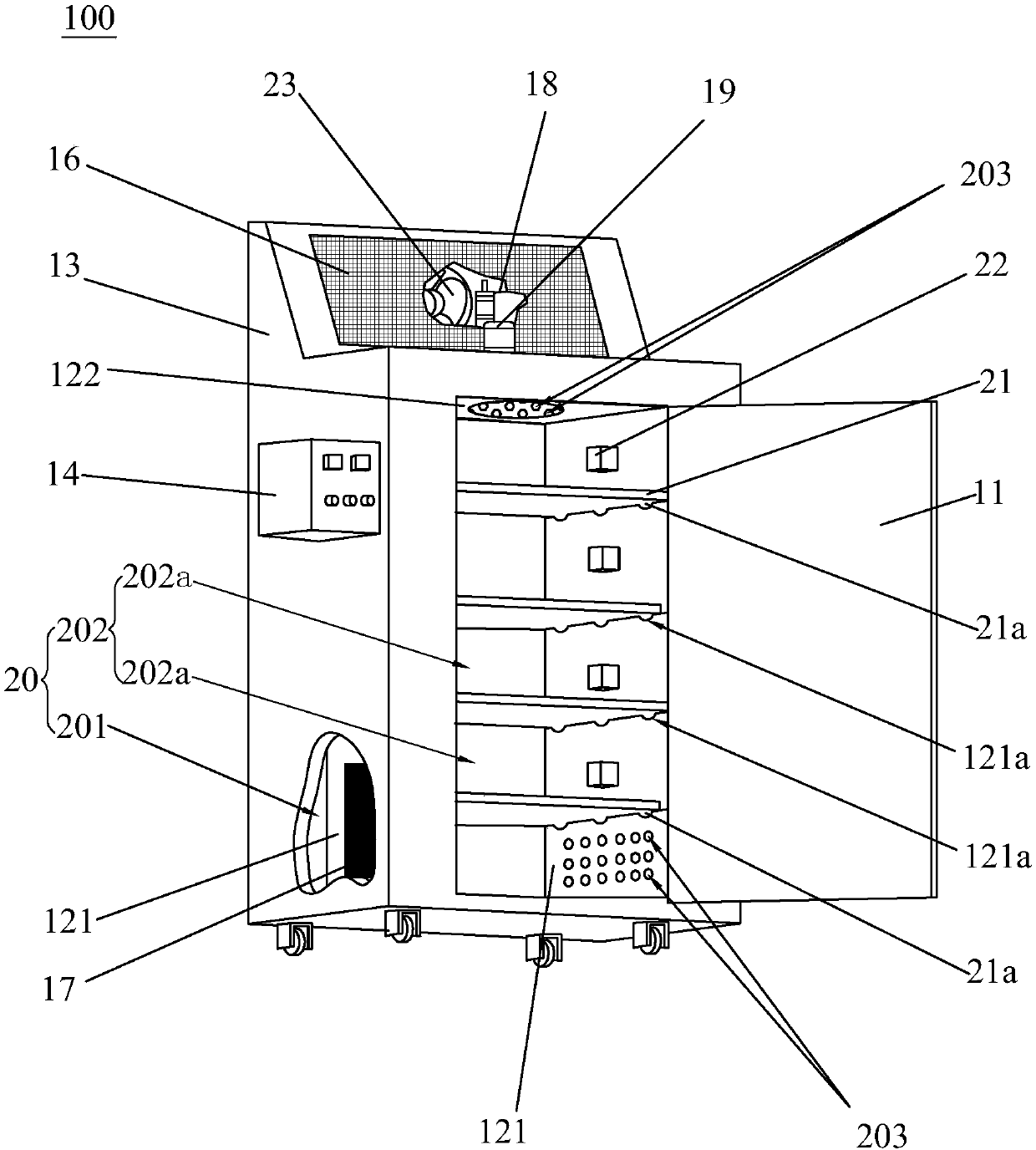

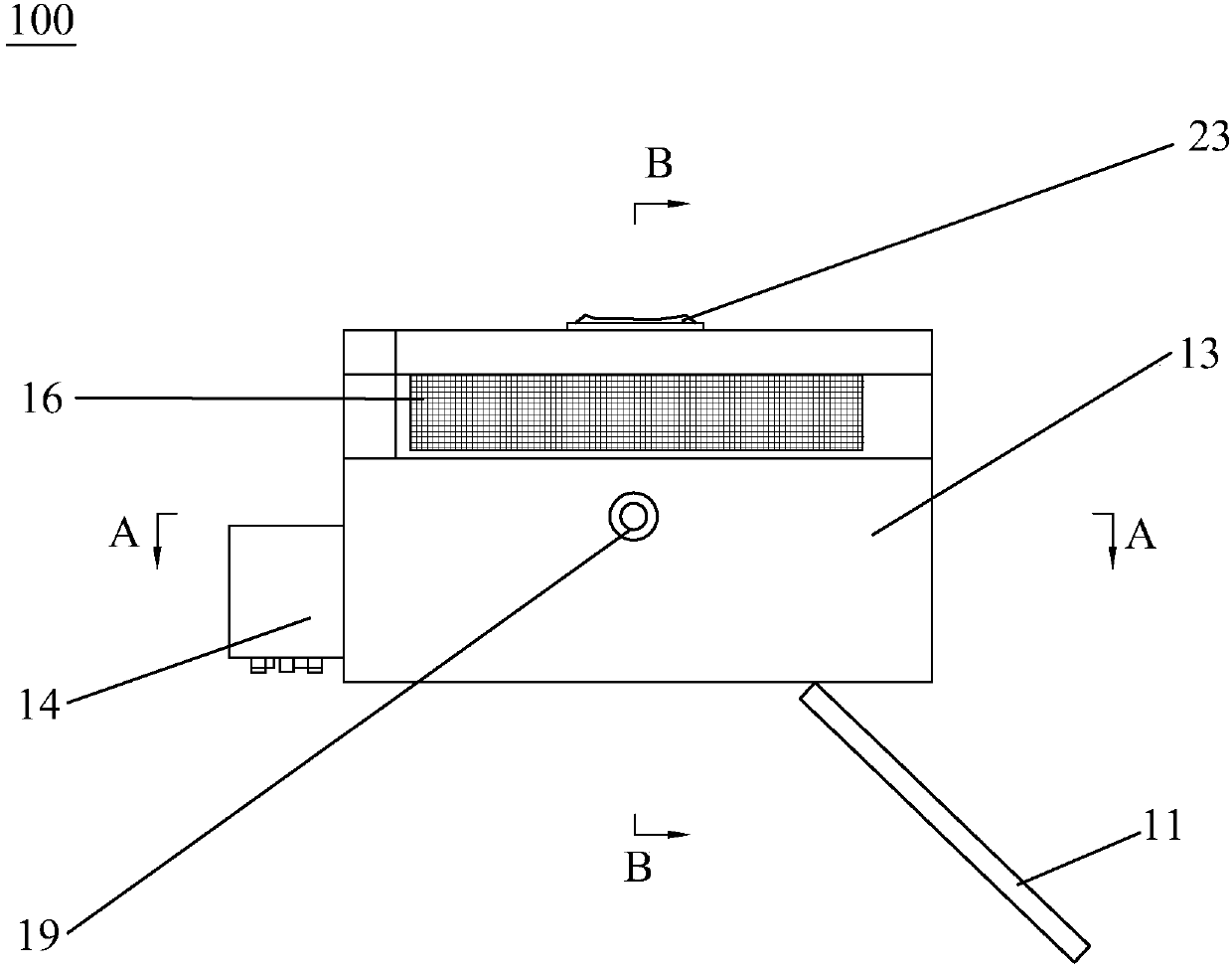

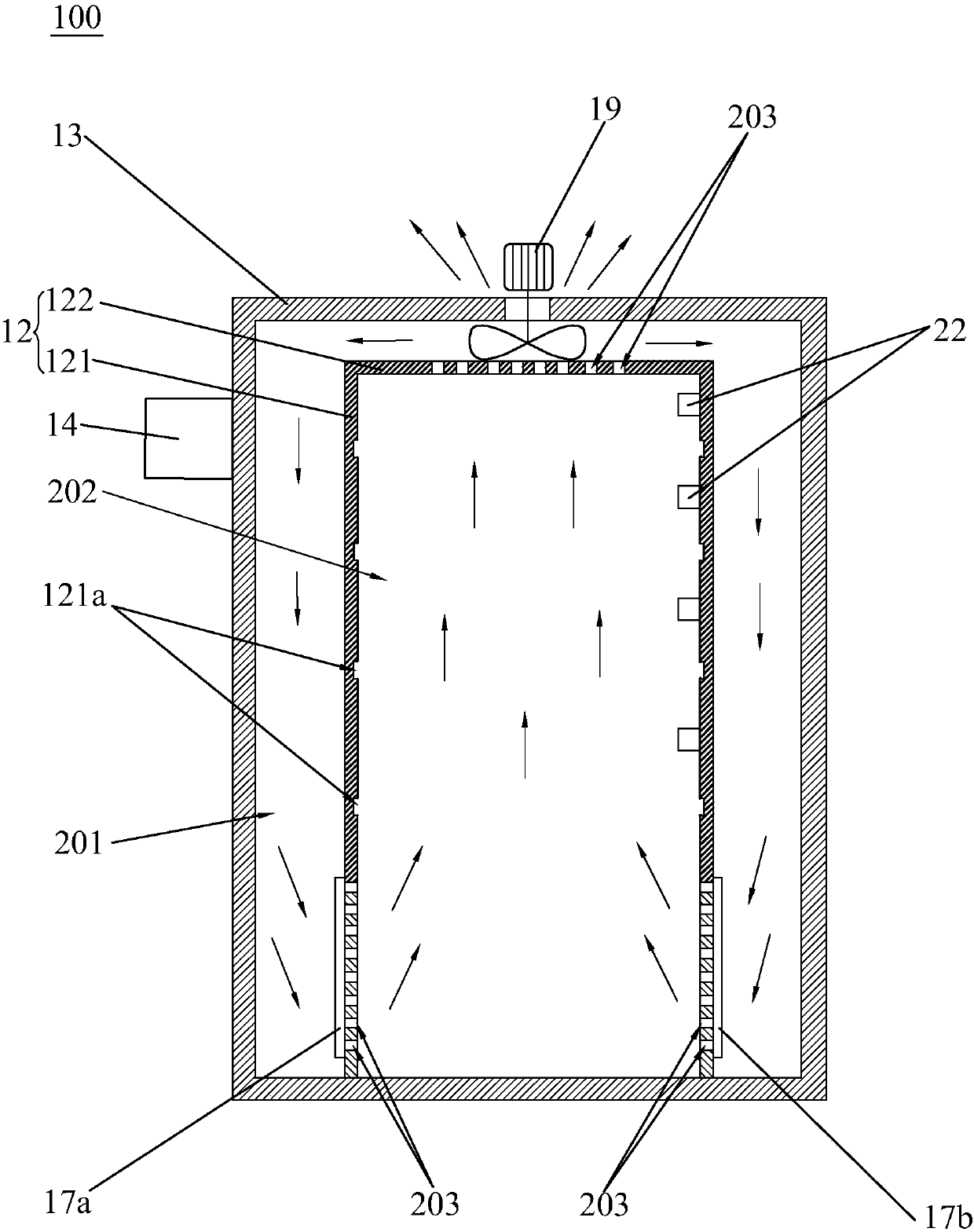

[0021] Please refer to figure 1 , image 3 and Figure 5 , the box-type heat pump drying box 100 of the present invention includes a box door 11, a door-shaped partition 12, a box body 13 with a hollow structure, a supporting plate 21, a controller 14, and an electronically controlled crossover electrically connected to the controller 14. Valve 15 , evaporator 16 , condenser 17 , compressor 18 , centrifugal fan 19 and sensor 22 . The box body 13 of the hollow structure forms a cavity 20 with an opening, and the box door 11 is installed on the box body 13 for the operator to selectively open or close the cavity 20 with the opening. Specifically, in this embodiment, The box door 11 is a transparent structure, so that the user can obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com