Temperature and leakage monitoring optical cable network based on heat distribution pipeline

A thermal pipeline and optical cable technology, which is applied in the field of thermal pipeline networking, can solve problems such as the complex environment and the impossibility of monitoring the entire network without blind spots, so as to promote safe operation, promote high-quality operation, and realize the whole process without blind zone leakage monitoring and The effect of abnormal temperature monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

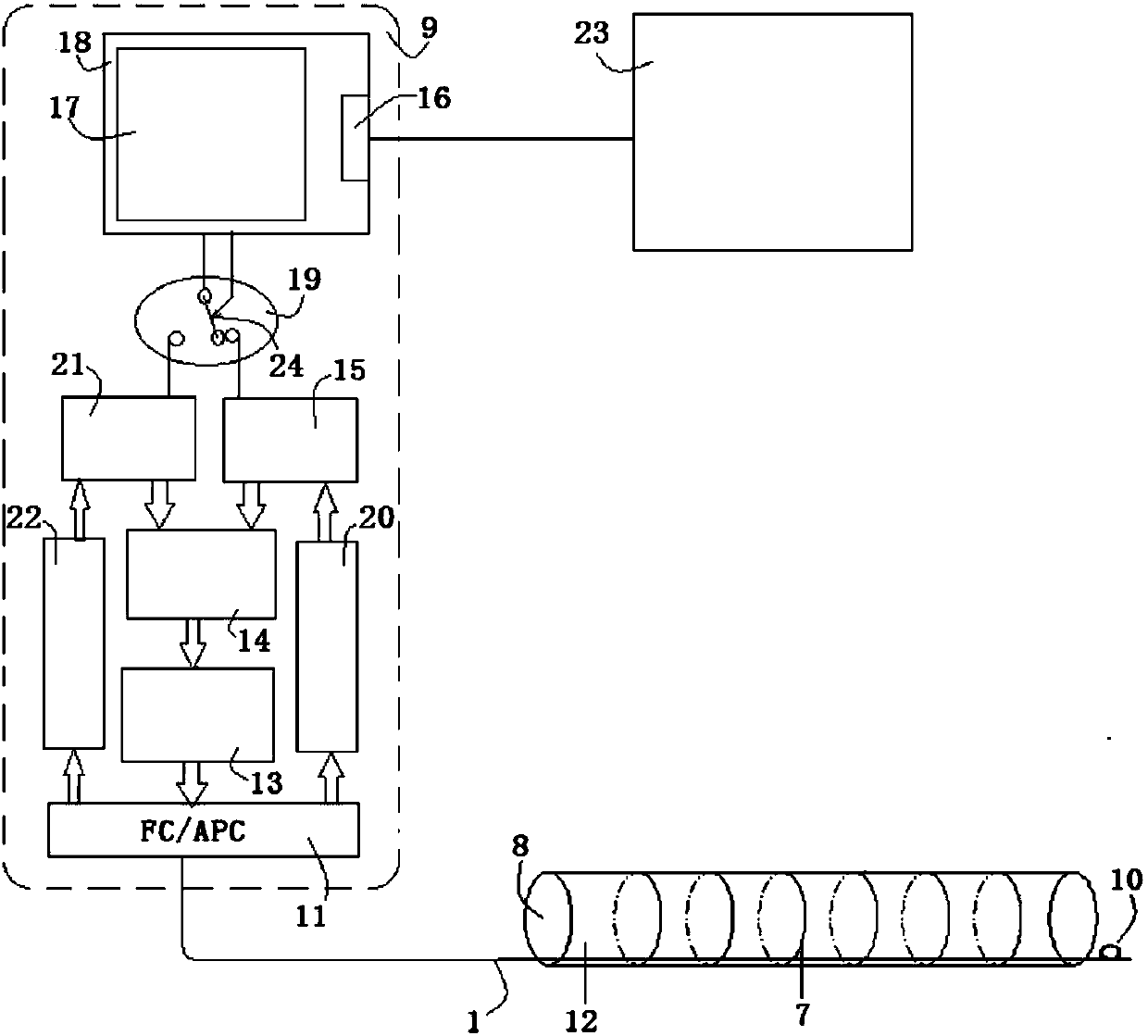

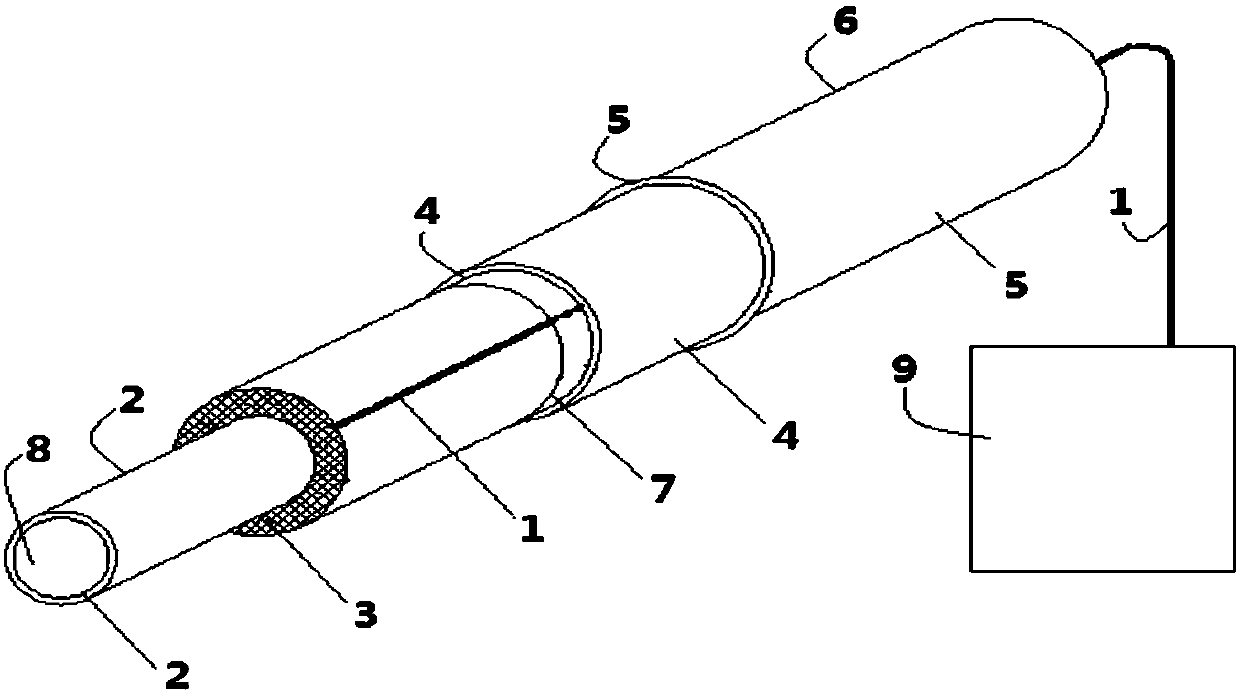

[0020] Below with the accompanying drawings ( Figure 1-Figure 2 ) to illustrate the present invention.

[0021] figure 1 It is a schematic diagram of the structure of the optical cable network for temperature measurement and leakage detection based on thermal pipelines for implementing the present invention. figure 2 It is a structural schematic diagram of a prefabricated optical cable thermal duct. Such as Figure 1 to Figure 2 As shown, based on the temperature measurement and leakage optical cable network of the thermal pipeline, the thermal pipeline of the thermal pipeline network is used as the carrier to lay the optical cable 1 along the whole process of the thermal pipeline to form an optical cable network. The monitoring host 9 is distributed in the optical cable network. The monitoring host 9 Including an industrial computer 18, the industrial computer 18 is respectively connected to the leak detection module 15 and the temperature measurement module 21 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com