Device and method for detecting material mixing uniformity by means of near-infrared technology based on MEMS(micro-electro mechanical system)

A technology for technical detection and uniformity, which is applied in the field of near-infrared online detection of mixing uniformity, can solve the problems of difficulty in reflecting the instantaneous change trend of the mixing process in real time, the inability to get rid of the steps of manually extracting samples, and the backward technical means. Improve the overall efficiency of mixing, light weight and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

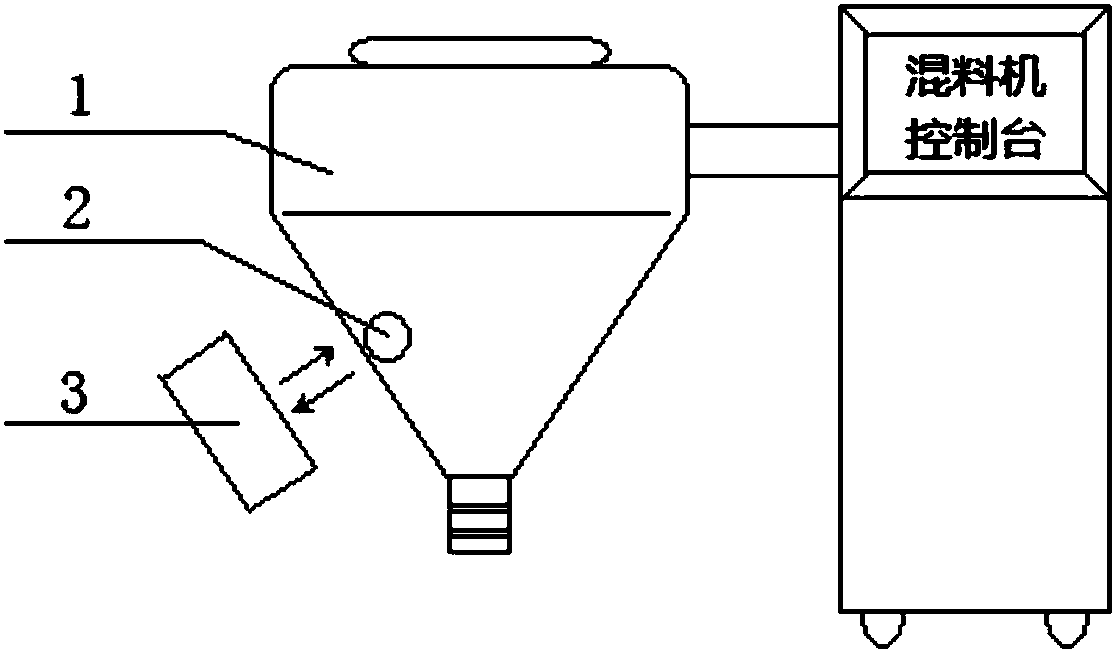

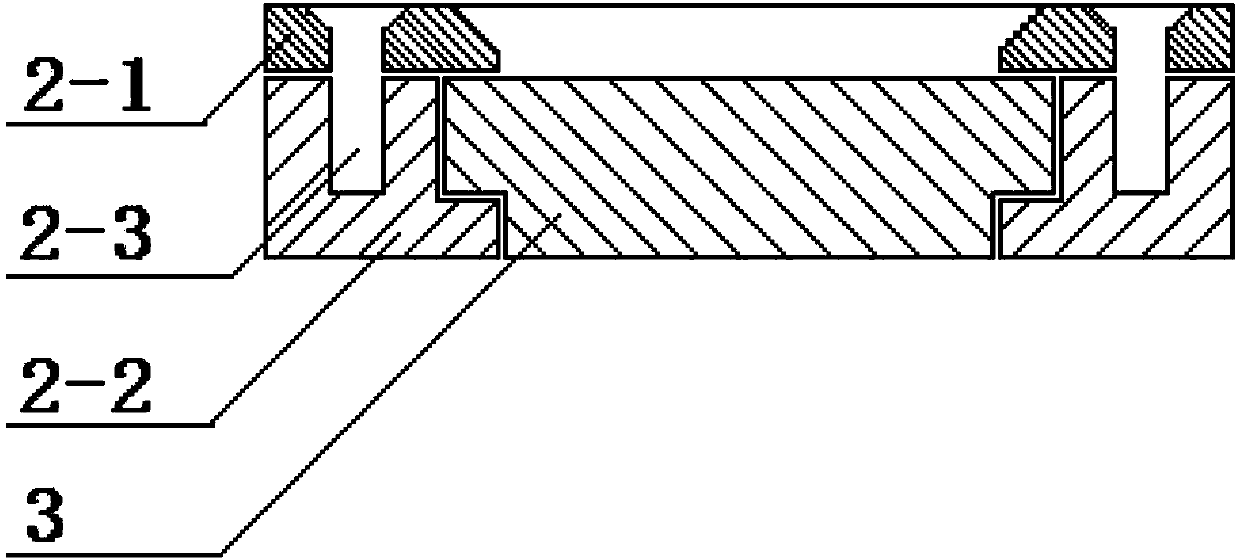

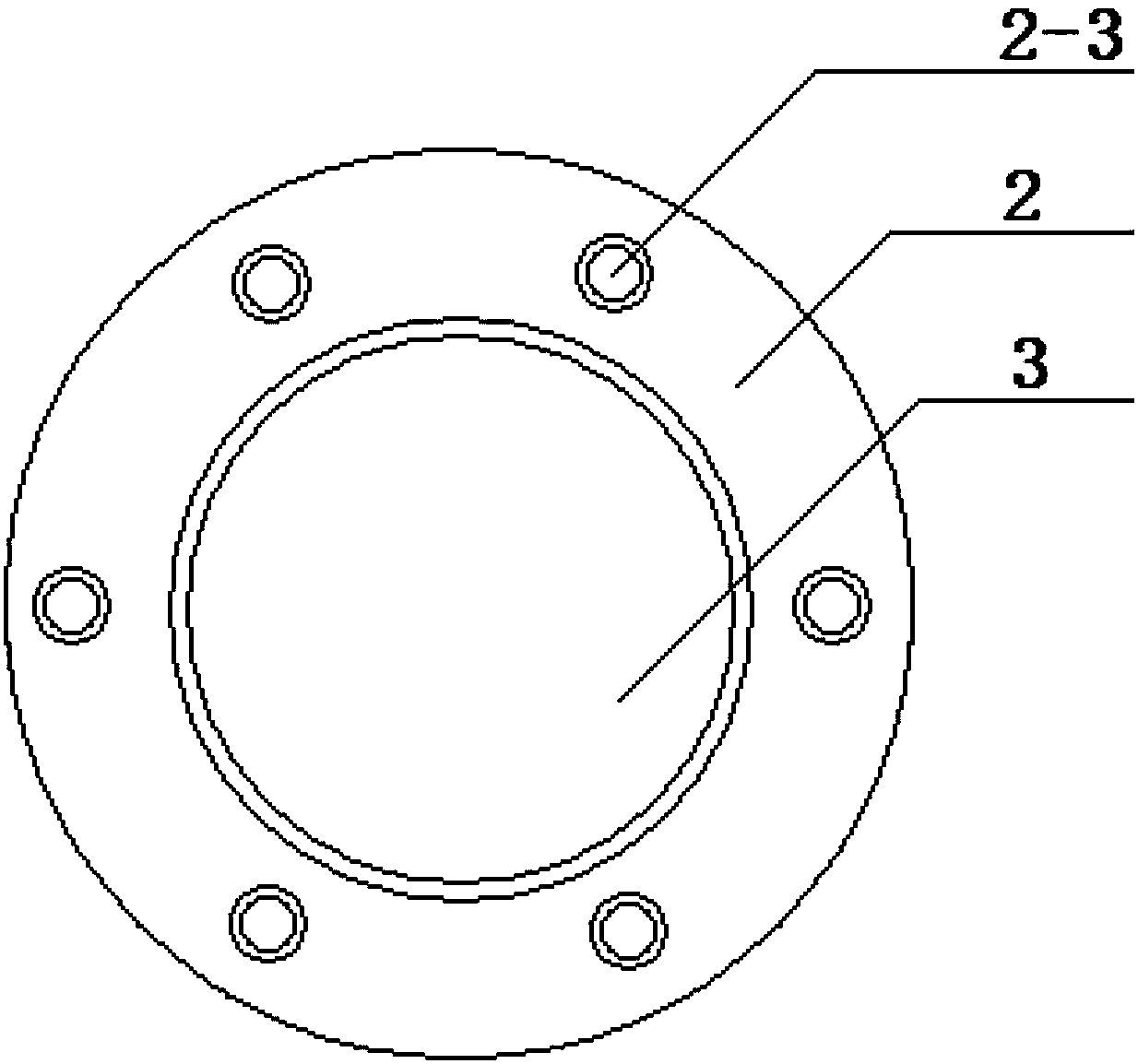

[0037] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a device for online detection of mixing uniformity based on MEMS near-infrared technology, the device includes a window structure 2, and the window structure 2 is installed on the side wall of the mixing tank 1; The near-infrared spectrometer is installed on the outside of the window structure 2, and the detection signal of the near-infrared spectrometer probe passes through the window structure 2 to detect the mixture in the mixing tank 1. The window structure 2 includes a flange 2-2, and a lens is clamped in the opening in the middle of the flange 2-2. The clamping method of the flange 2-2 and the lens is: the lens is embedded in the opening, the edge of the lens is pressed by the flange cover 2-1, and the flange cover 2-1 is connected by the thread 2-3 The way is fixed on the flange 2-2. The lens is a sapphire lens3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com