System for simulating detection of assimilation temperature of iron ore powder under different conditions

A detection system and technology of iron ore powder, applied in the investigation stage/state change and other directions, can solve the problems of affecting the clarity of the assimilation process of the sample captured by the camera, affecting the accuracy of the assimilation temperature detection, and damage to the lens of the camera. temperature, reduce temperature fluctuations, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

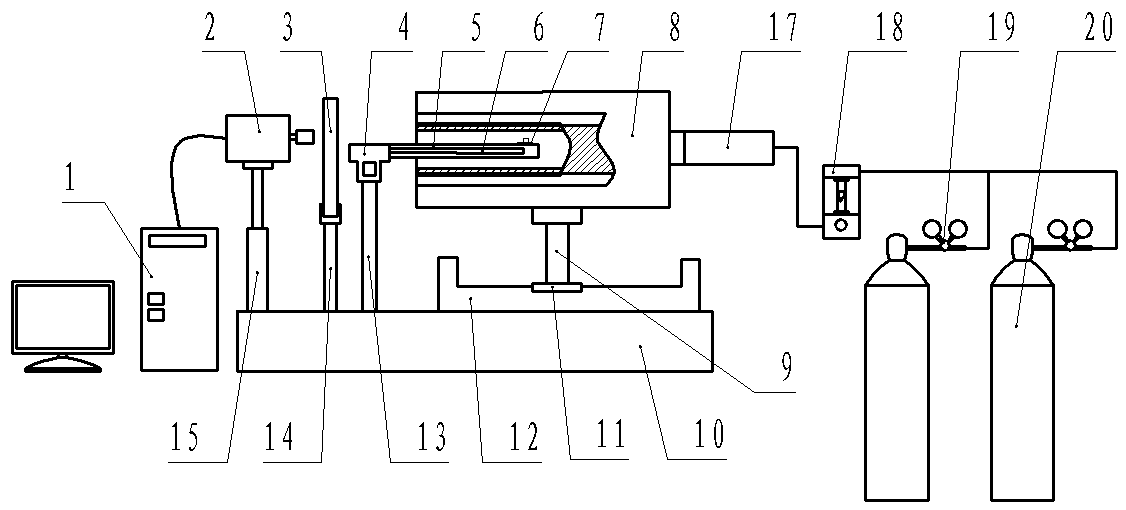

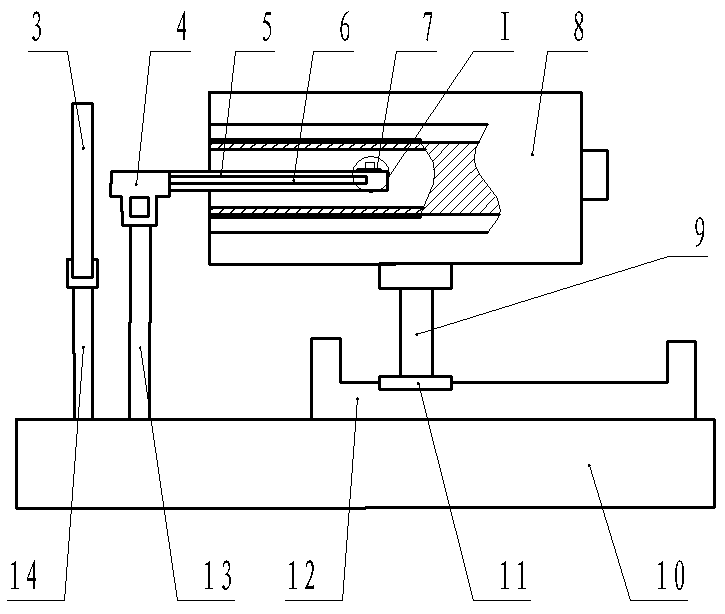

[0021] Such as figure 1 , figure 2 A temperature detection system for iron ore powder assimilation that simulates different conditions is shown, including a heating furnace 8, a gas supply device, a camera 2 and a computer 1, the computer 1 is connected to the camera 2 in communication, and the heating furnace 8 is connected through a preheating component 17 The gas supply device includes two gas cylinders 20, the gas cylinders 20 are equipped with flow control valves 19, the two flow control valves 19 are connected to the flow meter 18 through the gas pipe, and the flow meter 18 is connected to the preheating component 17 through the gas pipe. Two flow control valves 19 control the gas to pass into the heating furnace 8 after being preheated according to a certain ratio and flow rate. By adjusting the gas flow rate of different gas cylinders 20, the partial pressure of oxygen in the gas can be adjusted, and then different reaction atmospheres can be adjusted. A support 13 i...

Embodiment 2

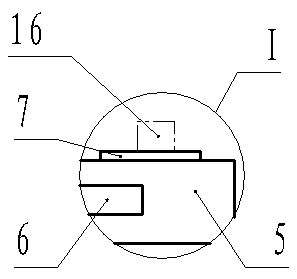

[0024] The difference between this embodiment and Embodiment 1 is that a scale is provided on the slide rail 12 along its length direction, and an indicator mark is provided on the slide block 11. When the cross strut 5 just enters the heating furnace 8, the The index mark is aligned with the zero point of the scale on the slide rail 12, such as Figure 4 shown. Thereby can accurately judge the position where the iron ore powder sample 16 enters the furnace cavity of the heating furnace 8, guarantee that the iron ore powder sample 16 is sent to the constant temperature zone of the heating furnace 8 furnace cavity, because the temperature fluctuation in the constant temperature zone is small, the assimilation process can be improved. Accuracy of temperature detection. In addition, during the continuous experiment, the iron ore powder sample 16 can be pushed into the furnace chamber of the heating furnace 8 in stages, so as to meet the dual effects of preheating in the early st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com