A defocus-based non-uniform correction analysis method for infrared imaging system

An infrared imaging system and non-uniform correction technology, which is applied in the field of optical simulation, can solve the problems of large temperature difference between the correction screen and the actual environment, and the large temperature difference between the baffle temperature and the outside world, so as to improve the ability of target discovery and recognition, and the actual effect is remarkable. good authenticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

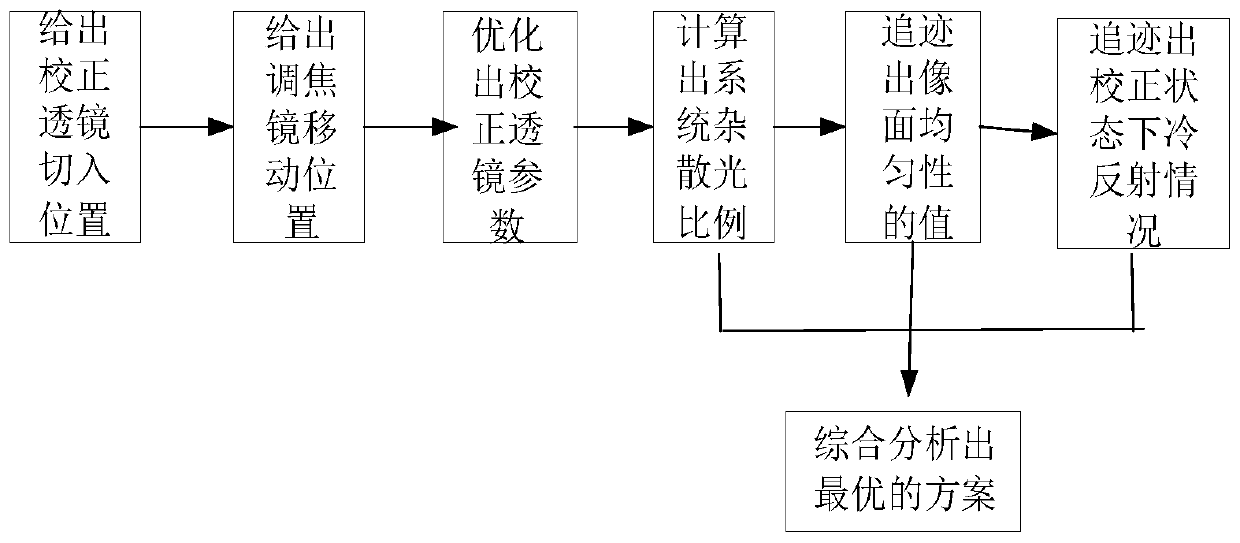

[0022] Step 1: Place the correction lens between convergence one and convergence two in the continuous focusing infrared imaging system; the material of the correction lens is germanium, and the cut-in position of the correction lens is: the distance from the rear surface of the correction lens to the front surface of the convergence lens 2 7.62mm;

[0023] Step 2: In the optical simulation software, the uniformity of the focal plane of the continuous focusing infrared imaging system is used as a constraint condition, and the moving position of the focusing mirror is used as a variable, and the least square method is used to automatically optimize, and all the focusing conditions that meet the constraints are obtained. The shift position of the focal lens is described;

[0024] Step 3: In the optical simulation software, the uniformity of the focal plane of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com