Special adjustable support structure of amorphous transformer

A support structure and transformer technology, applied in the direction of transformer/reactor installation/support/suspension, etc., can solve the problems of inconvenient installation of amorphous transformers, and achieve the effects of firmness, reliability, high structural strength, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

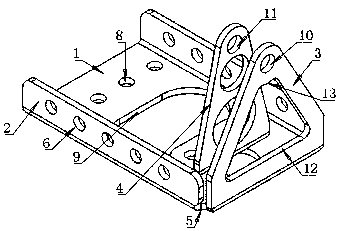

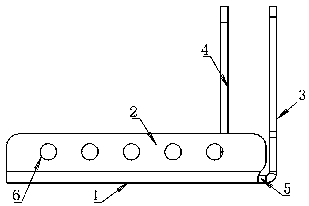

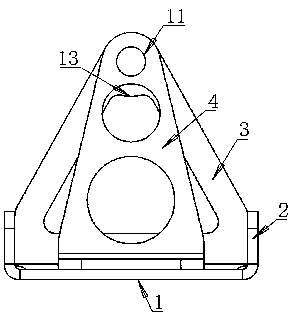

[0020] Such as Figure 1 to Figure 7 As shown, a special adjustable support structure for amorphous transformers, when in use, first fix the support structure at the bottom of the amorphous transformer to make them a whole structure, and then place it on the final fixing frame During the connection and fixing process, the fixed position can be adjusted according to the actual needs. Not only is the efficiency higher in the process of assembling and fixing, the installation is more convenient, but also the firmness after installation is more reliable. , It is easier to operate, and the loosening of the amorphous transformer can be effectively prevented after being installed and fixed, so that the safety and reliability of the amorphous transformer are higher during use. It includes a rectangular main body connection base plate 1, and the back side of the main body connection base plate 1 is connected with the amorphous transformer during use to fix them together. The front and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com