Battery cell grabbing structure

A technology of grasping structure and cell, applied in circuits, electrical components, primary batteries, etc., can solve problems such as poor blanking, long procurement cycle, cell shaking, etc., to achieve the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

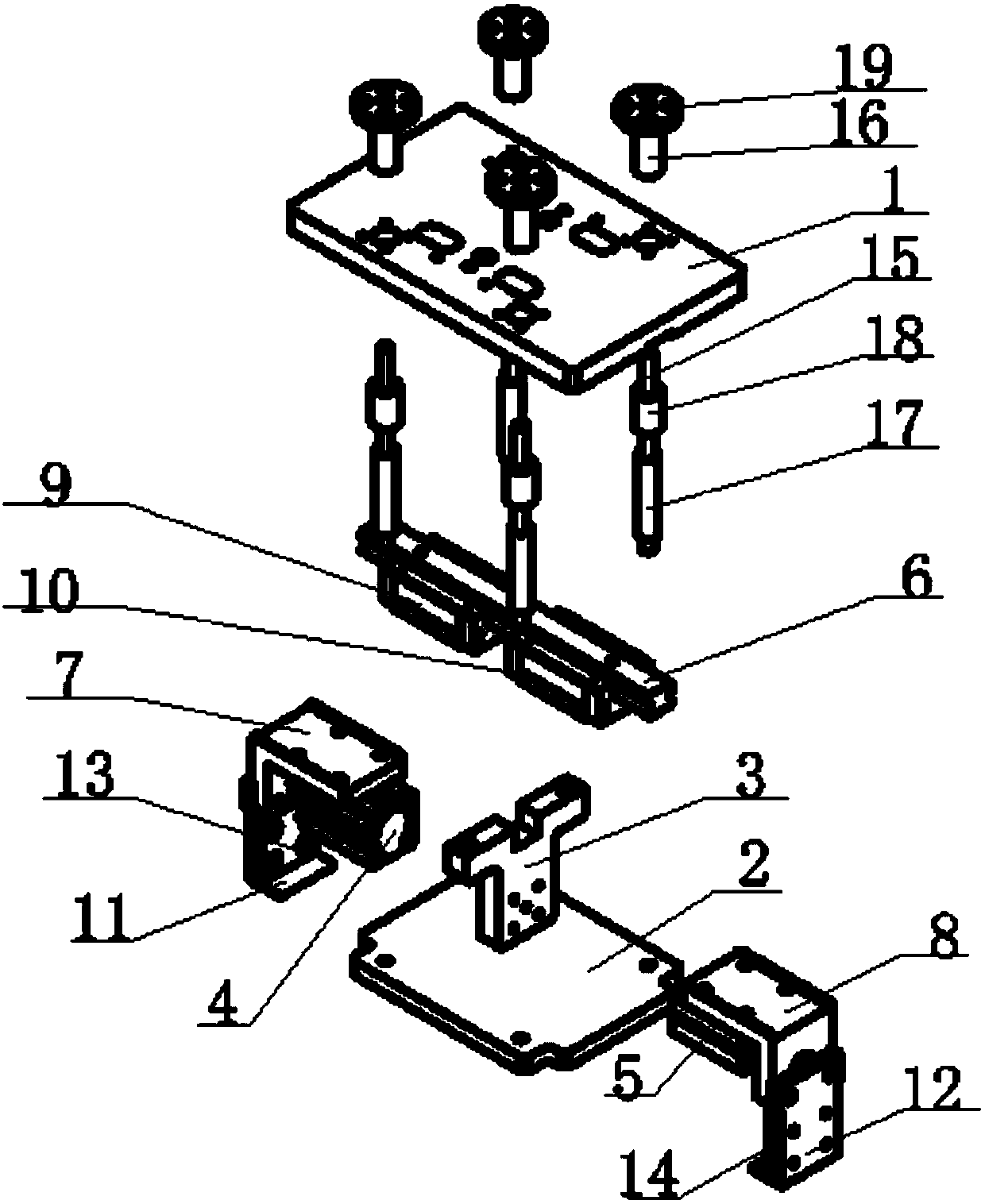

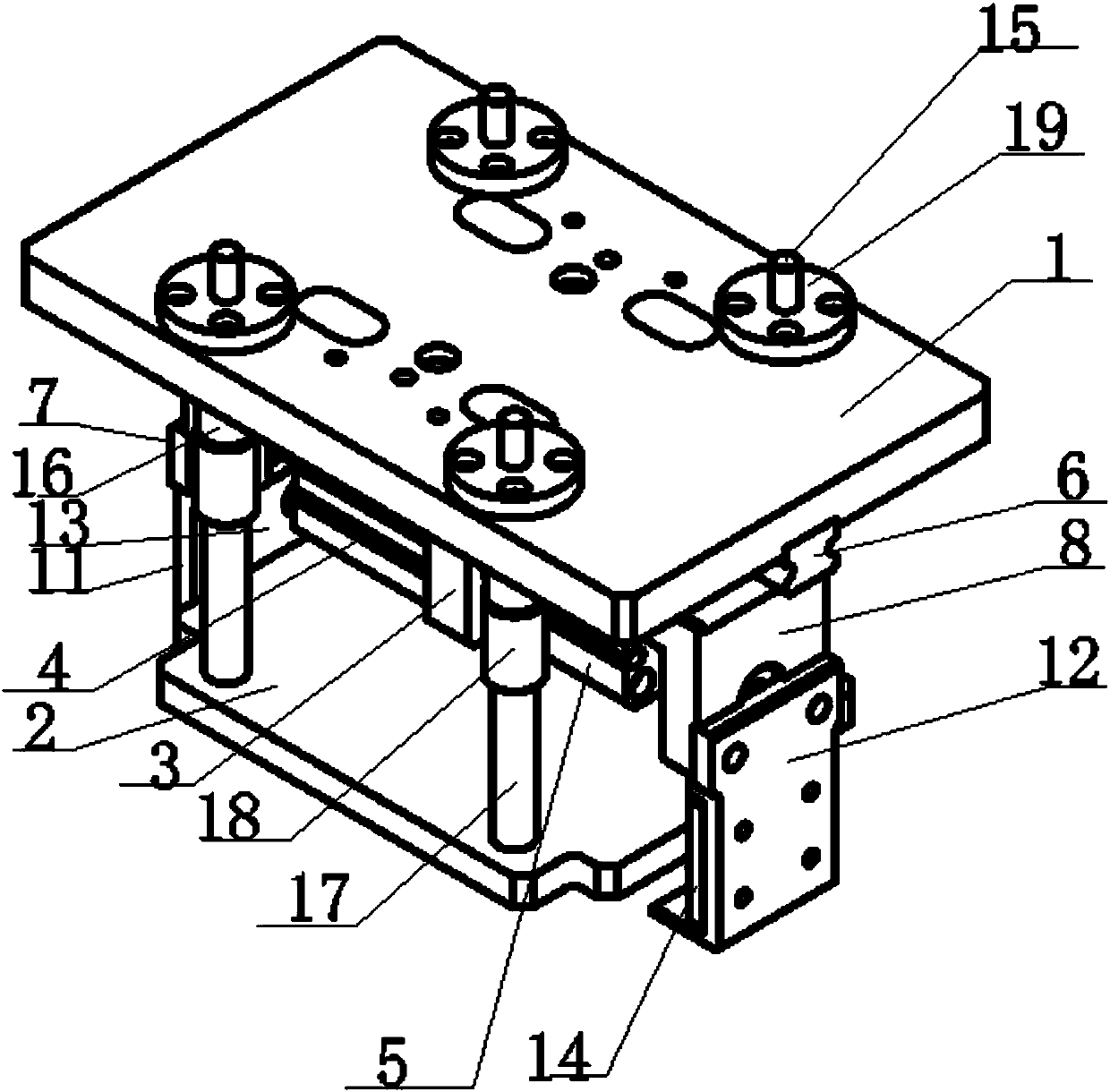

[0016] This embodiment provides a cell grasping structure, such as figure 1 and 2 As shown, it mainly consists of top plate 1, pressure plate 2, cylinder fixing plate 3, first cylinder 4, second cylinder 5, horizontal guide rail 6, first slider mounting plate 7, second slider mounting plate 8, first slider 9. The second slider 10, the left jaw 11, the right jaw 12, the first insulating plate 13, the second insulating plate 14, four guide shafts 15, four linear bearings 16, four springs 17, four spacers Cover 18 and four fixing rings 19 are formed.

[0017] Wherein, the first insulating plate 13 is installed on the inner side of the left jaw 11, the second insulating plate 14 is installed on the inner side of the right jaw 12, the left jaw 11 is installed on the bottom of the first slider mounting plate 7, and the right jaw 12 Installed on the bottom of the second slider mounting plate 8.

[0018] The fixed ends of the first cylinder 4 and the second cylinder 5 with differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com