Ceramic support of heat gun heating core

A ceramic bracket and heating core technology, applied in the direction of heating elements, ohmic resistance heating parts, etc., can solve the problems of uneven temperature of the resistance wire, affecting the service life of the heating wire, and the inability to carry out the heat of the heating wire, etc., to achieve the goal of increasing the temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, content of the present invention will be further described:

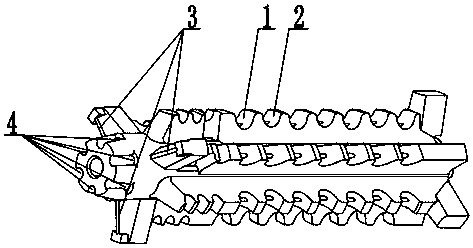

[0011] As shown in the figure is the structure diagram of the ceramic bracket of the heating core of the heat gun, including the first installation groove 1, the second installation groove 2, the air guide surface 3 and the wire introduction hole 4.

[0012] 1. The ceramic bracket is a columnar structure, and several installation brackets are evenly arranged on the column body. There are spiral installation grooves on the installation bracket. The heating wire is wound on the bracket in a spiral manner, and the heating wire installation groove of the heating wire ceramic bracket adopts a spiral shape. ; When installing the heating wire, it is wound along the spiral installation groove. This greatly improves the point contact problem between the heating wire and the mounting groove.

[0013] 2. The ceramic bracket adopts a double-helix installation groove struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com