Noise reduction ultrasonic rotary microchannel heat exchanger for data room

A data room, ultrasonic technology, applied in the field of energy saving and refrigeration, can solve the problems of large cooling water flow resistance, low heat transfer efficiency, ultrasonic cavitation effect can not fundamentally solve the problem of descaling, etc., to achieve improved heat transfer performance, Improvement of heat transfer effect and reduction of kinematic viscosity coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

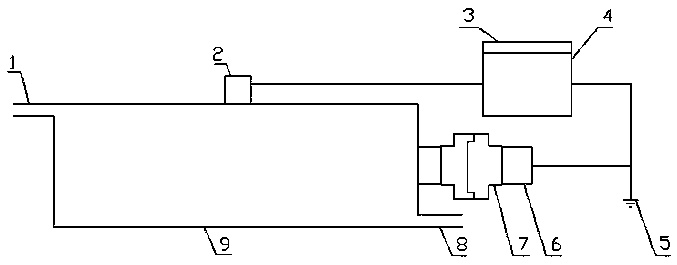

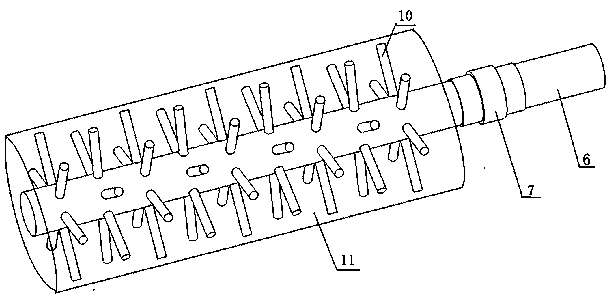

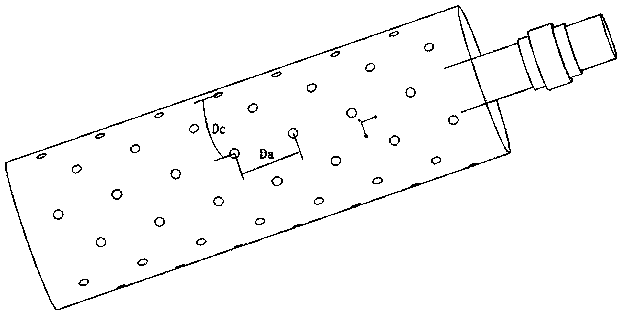

[0034] Such as figure 1 , figure 2 and image 3 As shown, a noise-reducing ultrasonic rotary micro-channel heat exchanger for a data center includes a heat exchange shell 9 , a cooling water channel 11 , a micro-fin tube assembly, an ultrasonic generator 4 and an ultrasonic transducer 2 .

[0035] The shape of the heat exchange shell is preferably cylindrical, and the material is preferably red copper.

[0036] The heat exchange housing is arranged on the cooling plate of the server mainframe in the data room; one end of the ultrasonic generator is preferably connected with the power supply 5 through a wire, and the other end of the ultrasonic generator is preferably connected with the ultrasonic transducer through a wire, and the ultrasonic transducer The device is arranged on the outer wall of the heat exchange shell. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com