Temperature controlling system of holding furnace capable of continuously preparing aluminum alloy semi-solid state sizing agent

A temperature control system, a technology for semi-solid slurry, applied in furnace control devices, configuration of indicating equipment/measuring equipment, furnaces, etc., can solve problems such as restricting technology promotion and application, poor temperature control effect, and affecting casting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

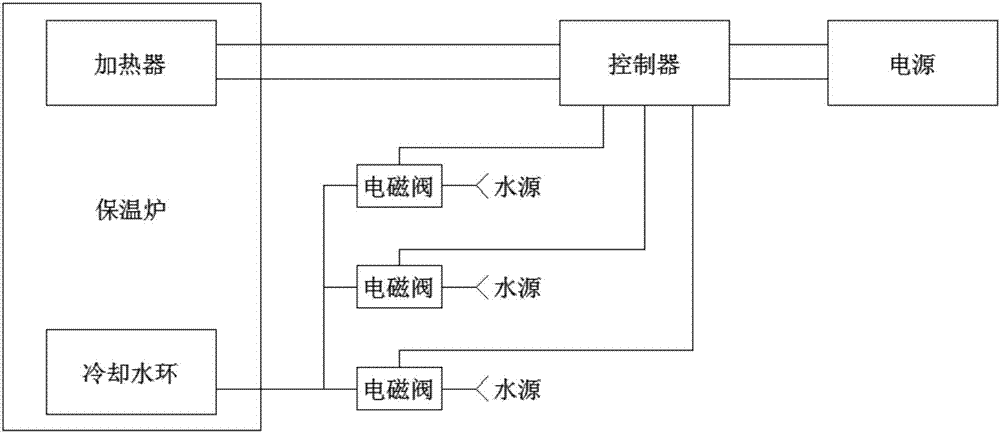

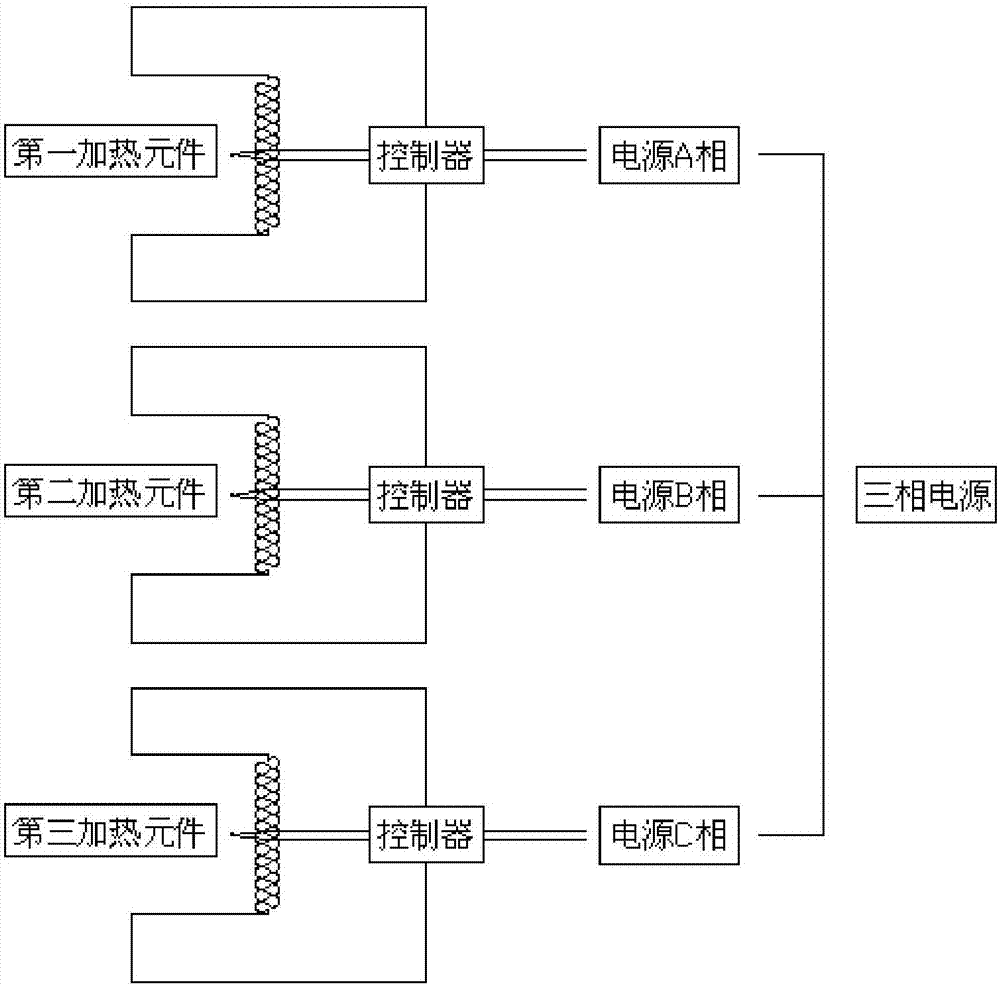

[0015] see figure 1 and 2 , is a temperature control system for continuously preparing aluminum alloy semi-solid slurry holding furnace as the best embodiment of the present invention, including a heating system, and the heating system includes a heater, a controller and a power supply, and the controller and connected to the power supply, and connected to the heater at the same time to control the temperature of the heater; the heater has more than 2 heating elements, each heating element is arranged up and down in the vertical direction, and each heating element is equipped with a thermocouple, and Each thermocouple is connected to a controller, and each controller performs PID adjustment on each heating element, so that each heating element is correspondingly heated to a different set temperature. It also includes a cooling system. The cooling system includes a heat conduction ring, a cooling water ring and a water volume controller. , the other end supplies water to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com