Vehicle chassis integration control method and system

A technology for control systems and automobile chassis, which is applied to control devices, vehicle components, and driver input parameters. Influence and coupling problems, to achieve the effect of improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

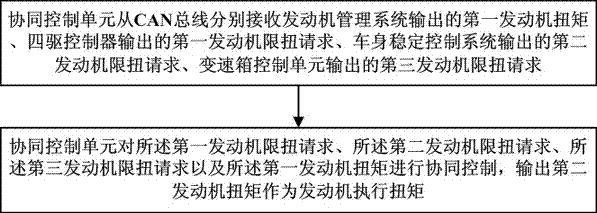

[0061] Corresponding to Embodiment 1 of the present invention, Embodiment 2 of the present invention provides an integrated control system for automobile chassis, including:

[0062] an engine management system for outputting a first engine torque;

[0063] A four-wheel drive controller, configured to output a first engine torque limit request;

[0064] The body stability control system is used to output the second engine torque limiting request;

[0065] a gearbox control unit, used to output the torque limit request of the third engine;

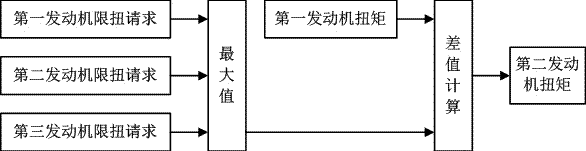

[0066] a coordinated control unit, configured to perform coordinated control on the first engine torque, the first engine torque limit request, the second engine torque limit request, and the third engine torque limit request respectively received from the CAN bus, The second engine torque is output as engine implementation torque.

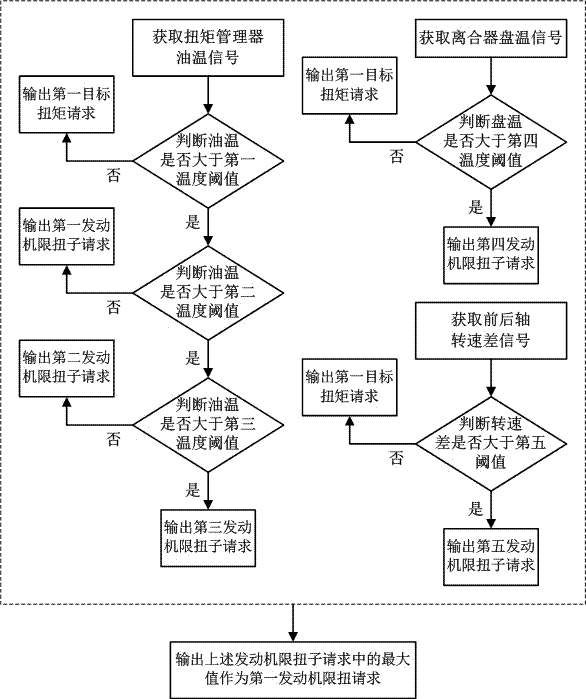

[0067] Wherein, the four-wheel drive controller obtains the corresponding engine torque limiting request ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com