Half-portal-frame crane adopting open type transmission and provided with lifting trolley and travelling trolley

A technology of running trolley and open transmission, applied in the direction of walking bridge cranes, cranes, traveling mechanisms, etc., can solve the problems of inconvenience, waste of manpower and material resources, etc. in the adjacent workshop, and achieve convenient adjustment, low price, Smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

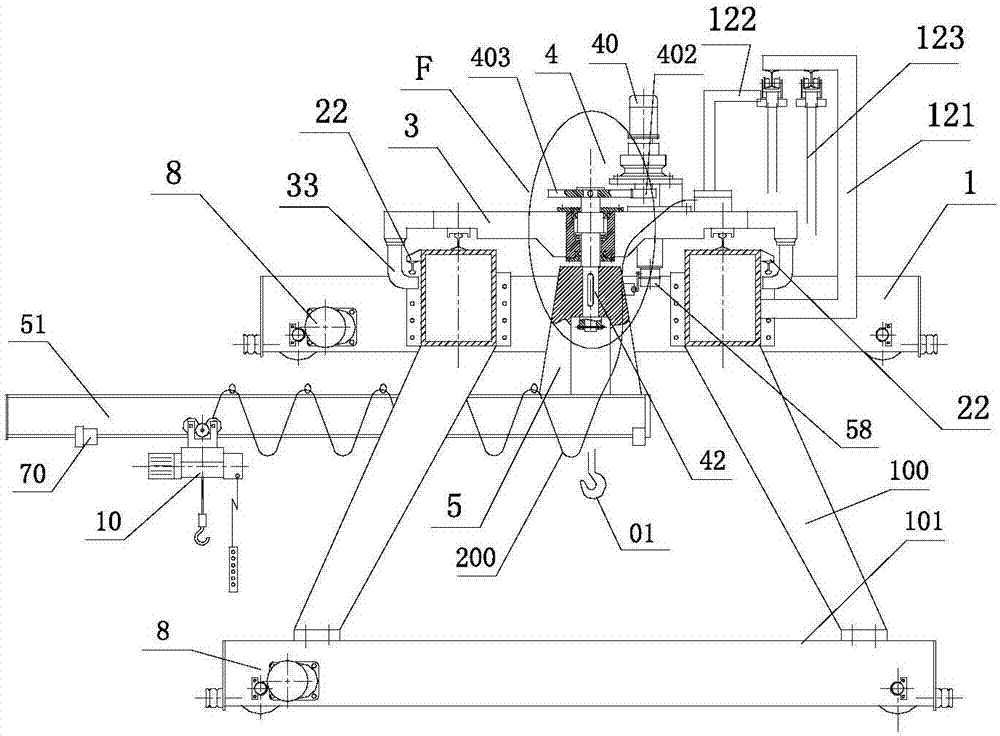

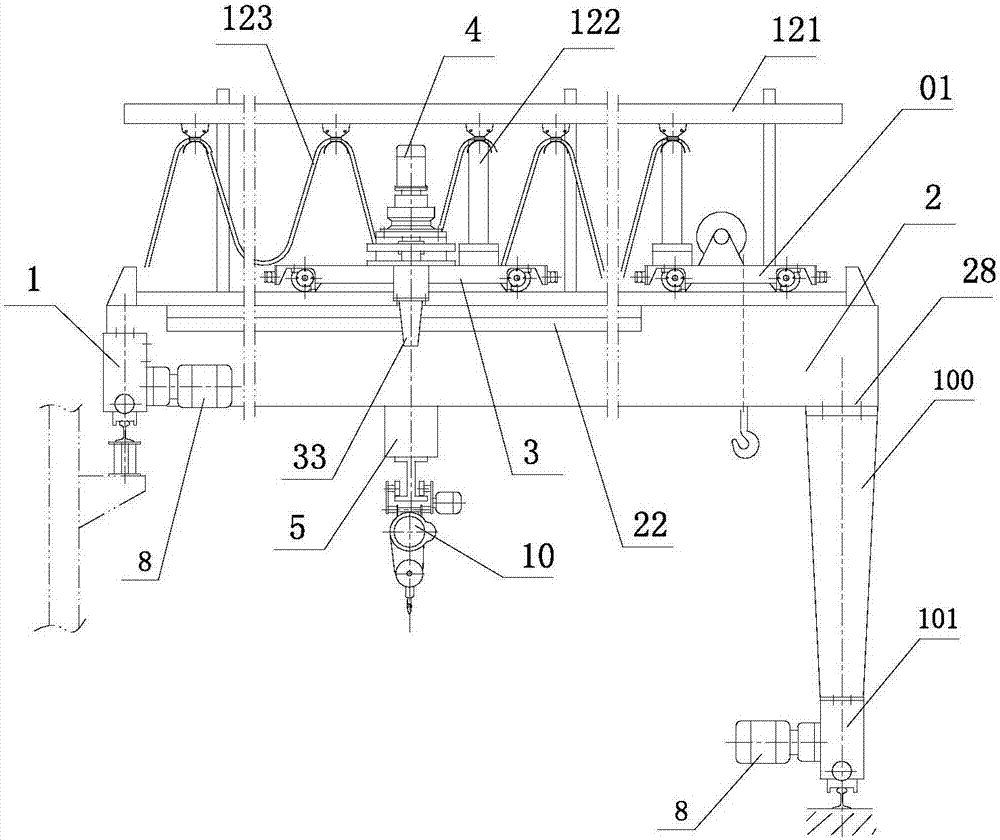

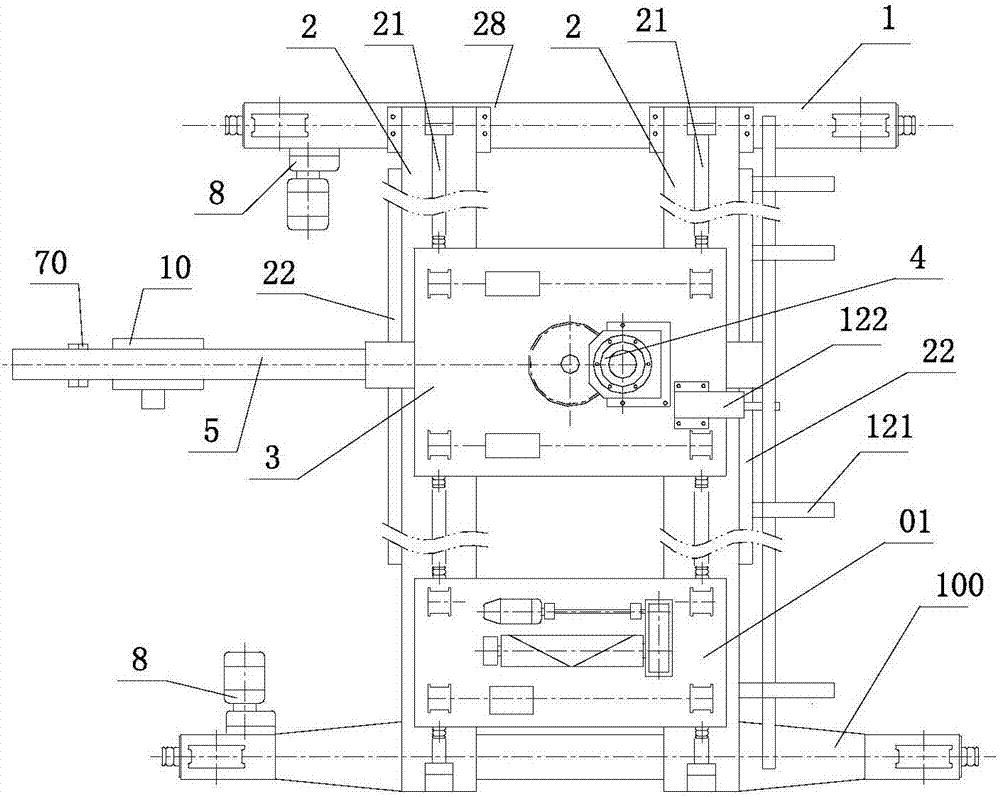

[0036] like figure 1 , figure 2 , image 3 As shown, a semi-gantry crane with a lifting trolley, a running trolley and an open transmission includes a semi-gantry 28, and the semi-gantry is composed of an end beam 1, two main beams 2, and a leg frame 100 , one end of the two main beams is connected to the end beam 1, and the other end is connected to the outrigger frame 100; the outrigger frame includes a ground beam 101; A lifting trolley 01 is connected to the track 21 above, and the wheel tread of the lifting trolley rides on the rail surface of the track 21; the lifting trolley has a hook type lifting mechanism; The running trolley 3, the wheel treads of the running trolley ride on the rail surface of the track 21, and can run; the electric pick frame 121 is provided with two groups of movable hanging cables 123; the two main girders Side rails 22 are arranged on the outer side of the side rails, and are parallel to the above-mentioned rails; the lower gap of the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com