Manufacture and installation method of energy-saving Maerz lime kiln shell

An installation method and Maerz technology, applied in the field of manufacturing and installation of Maerz lime kiln shells, can solve the problems of low installation cost and achieve the effects of low installation cost, safe and reliable construction, and flexible selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

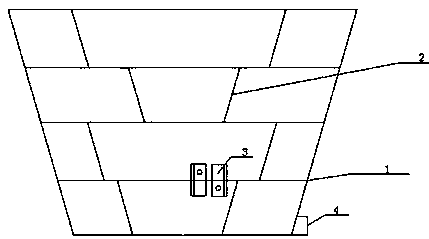

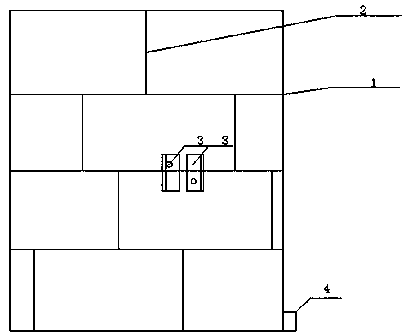

[0032] In the 1 million tons / year calcium carbide project of Zhongtai Chemical in Fukang City, Xinjiang, the first phase of 600,000 tons / year and the second phase of 300,000 tons / year lime kiln project, this production and installation method was used to complete the production and installation of 5 lime kilns.

[0033] The prefabrication of the steel structure of the kiln shell in each section requires rolling and welding of steel plates according to the approved layout diagram, and non-destructive testing of welds at the same time. After confirming that the welding quality is qualified, proceed to the next process.

[0034] The specific implementation steps are as follows:

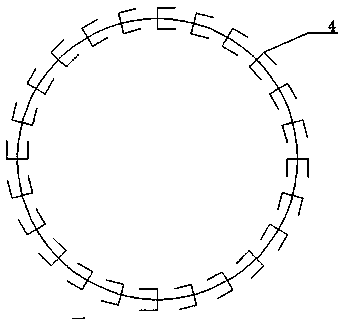

[0035] (1) In the prefabrication stage, use the truss car and the three-roll plate rolling machine to roll each steel plate of the kiln shell according to the calculated arc.

[0036] (2) Positioner design: The positioner is an auxiliary tool used to control the radian of each belt plate and the overall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com