One-way multi-point locking handle for doors and windows

A multi-point lock and handle technology, applied in door/window accessories, spherical handles of wing sashes, building locks, etc., can solve the problems of complex manufacturing process, complex manufacturing and assembly process, and high cost of zinc alloy, and achieve assembly positioning. Simple and precise, complex manufacturing process and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical solution of the present invention more clearly and completely, the present invention will be further described below in conjunction with the accompanying drawings.

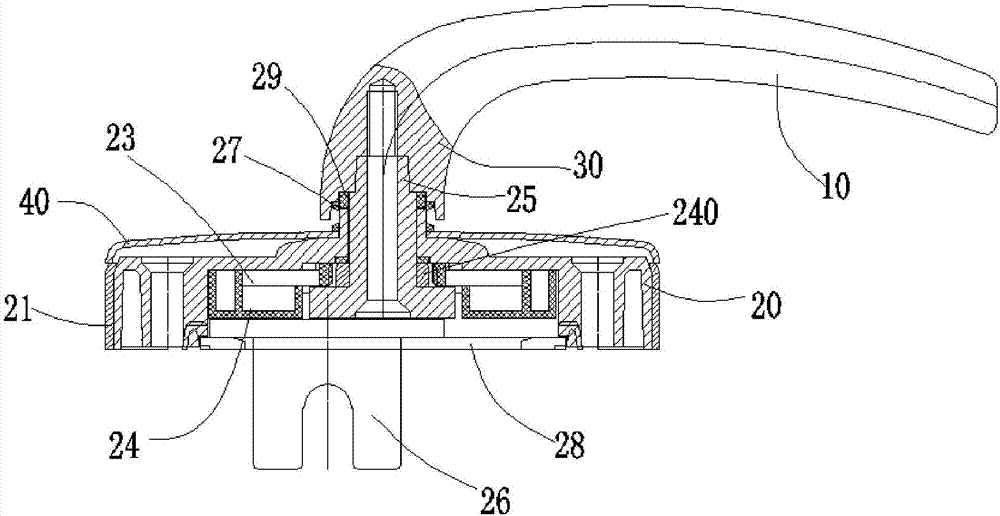

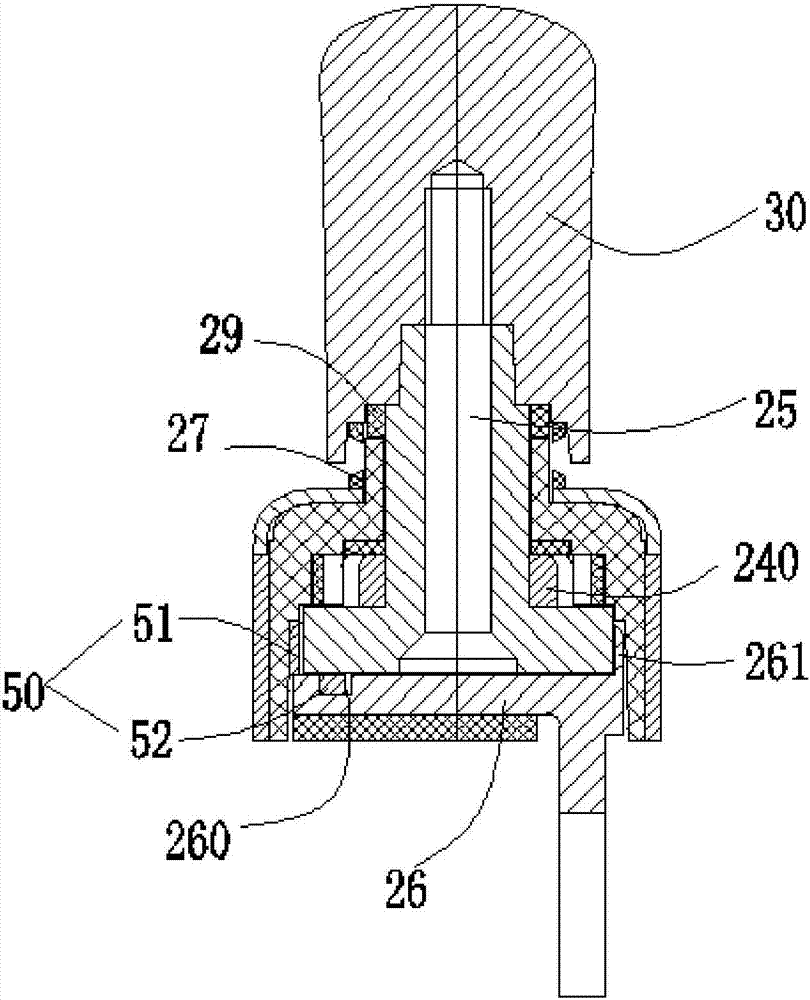

[0028] Please refer to Figure 1-Figure 8 , the present invention proposes a one-way multi-point lock handle 10 for doors and windows. The one-way multi-point lock handle 10 for doors and windows includes a handle 10 , a handle seat 20 and a connecting portion 30 .

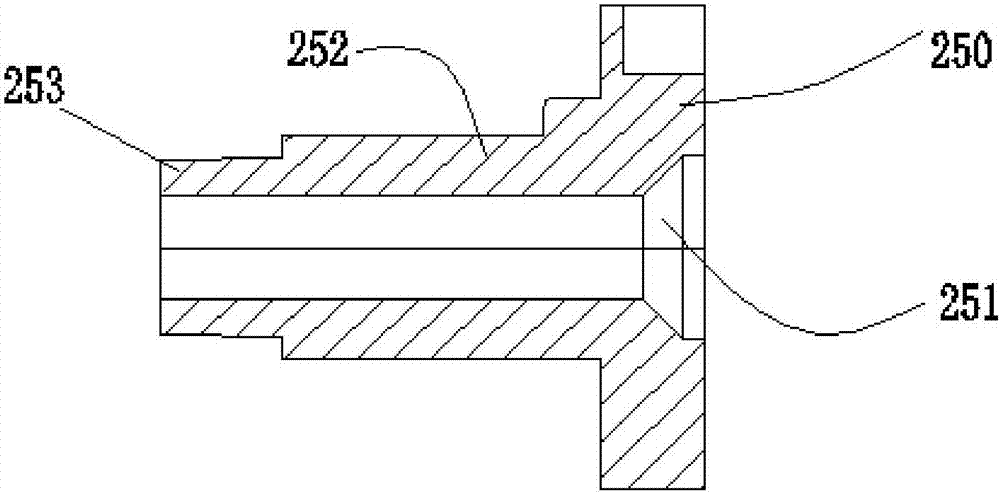

[0029] Specifically, the handle 10 is fixedly connected to the connecting portion 30, the handle base 20 includes a first shell 40, a second shell 21, and the second shell 21 protrudes upwards in the radial direction. The post hole 22 of the housing 21, the accommodation chamber 23 formed by the second casing 21, the supporting device 24 accommodated in the accommodation chamber 23, the fixed shaft 25, the shifting block device 26 and the locking tooth guide rail 50, the The boss hole 22 runs through the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com