Automobile accessory auxiliary refrigeration assembly

An auxiliary refrigeration and assembly technology, which is applied in the directions of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc. The effect of tripping and recovery operation, improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

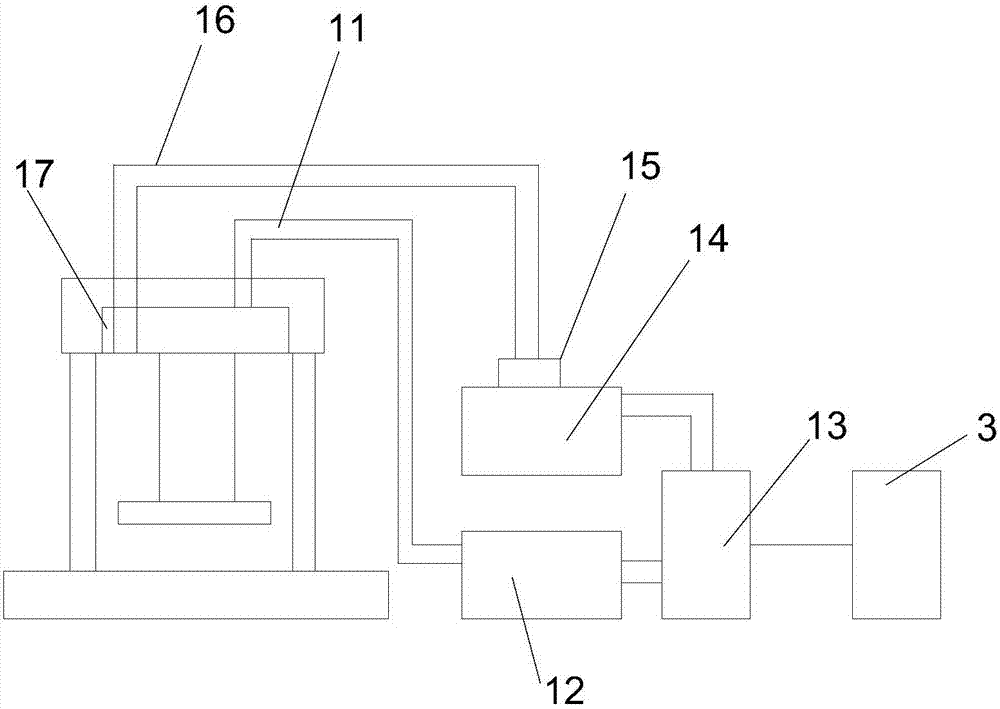

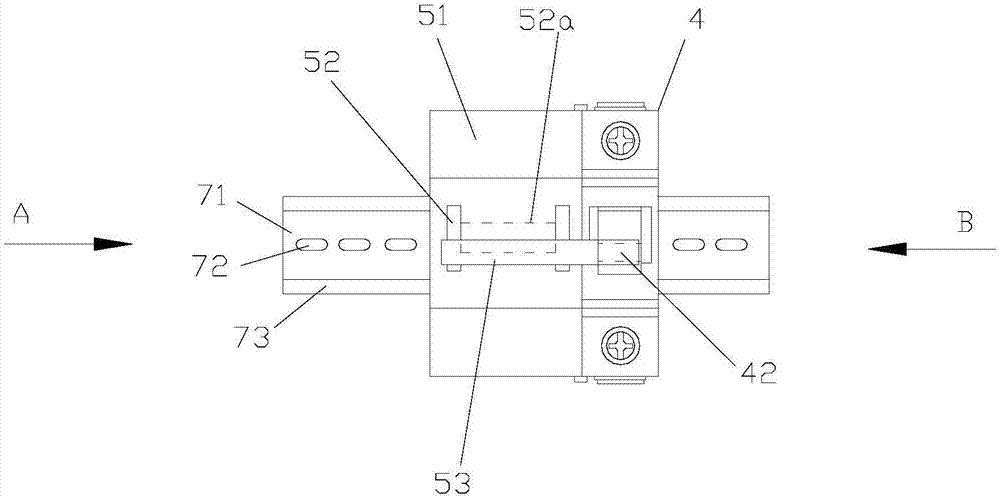

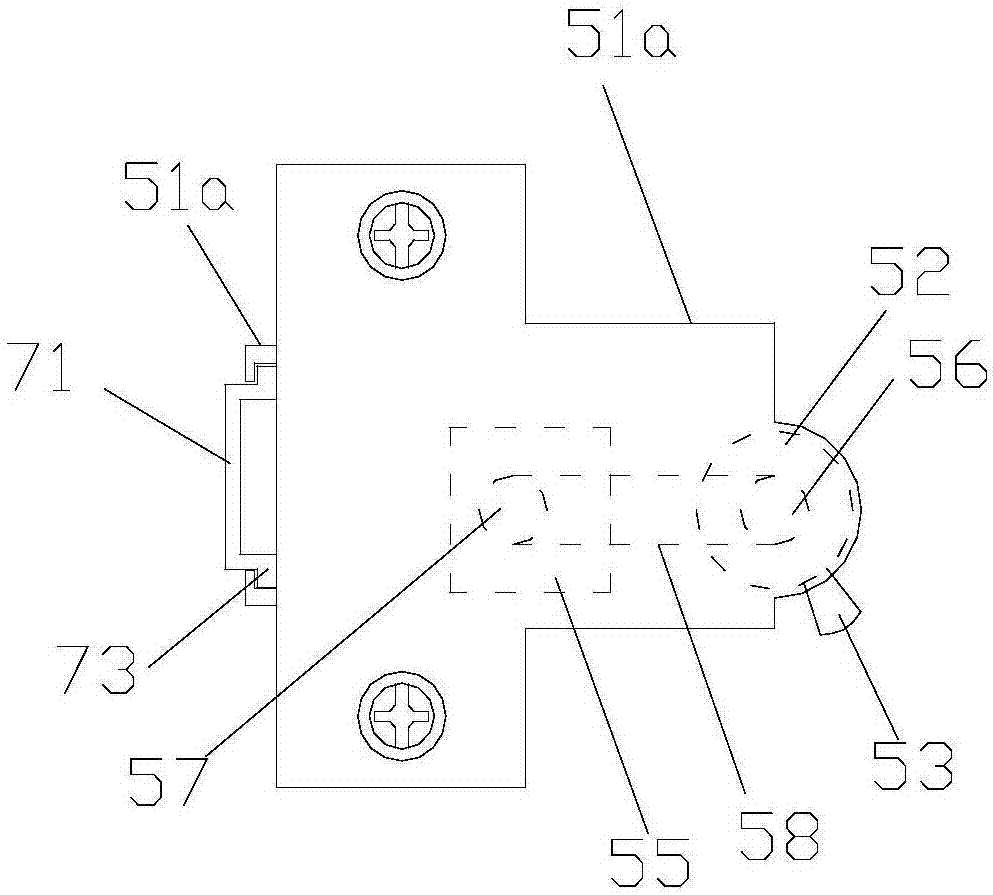

[0017] Such as Figure 1 to Figure 5 As shown: the auxiliary refrigeration assembly for auto parts in this embodiment includes a hot oil pipe 11, a hot oil tank 12, a refrigerator 13, a cold oil tank 14, an oil pump 15, a cold oil pipe 16 and a hydraulic oil tank 17, and one end of the hot oil pipe 11 is connected to the hydraulic oil tank 17 Connected, the other end leads to the hot oil tank 12, one end of the hot oil tank 12 is provided with a refrigerator 13, the other end of the refrigerator 13 is provided with a cold oil tank 14, the upper end of the cold oil tank 14 is provided with an oil pump 15, and the oil pump 15 leads to the hydraulic oil tank through the cold oil pipe 16 17. The refrigerator 13 is connected to the control box 3, and the control box 3 is provided with an air switch 4 for controlling the conduction of the circuit. A plate button 42 is provided; the control box 3 is also provided with a linkage 5 arranged side by side with the air switch 4; the linka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com