Circulating water waste heat recovery device and technology of evaporation unit

A waste heat recovery device and circulating water technology, which is applied in the field of mechanical devices, can solve the problems that the cooling effect is greatly affected by the ambient temperature, waste of heat, waste of water resources, etc., and achieve the effects of reducing steam consumption, reducing production costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

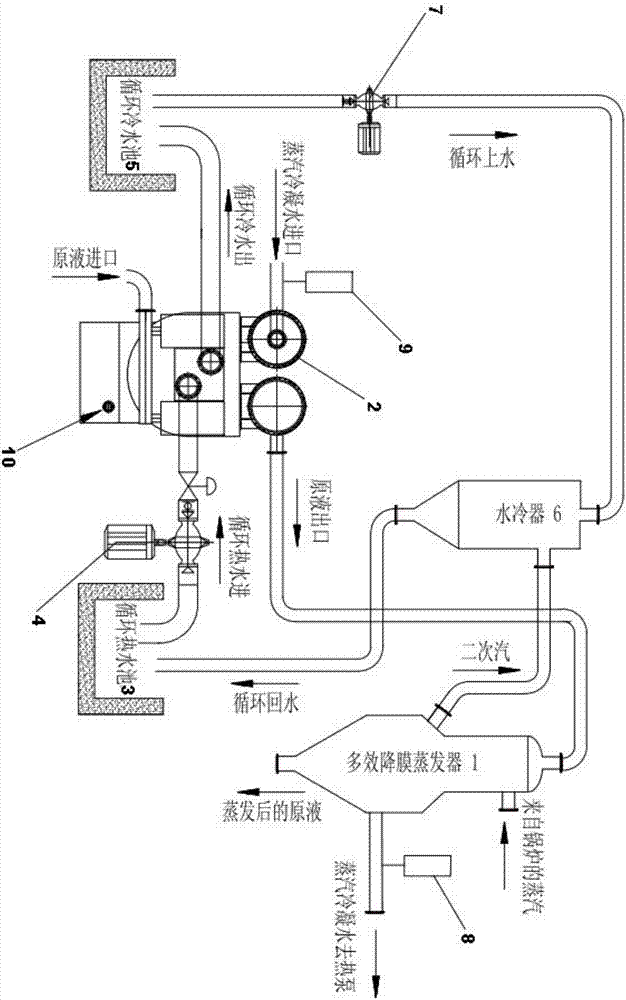

[0030] Such as figure 1 The shown embodiment is a waste heat recovery device for circulating water of an evaporating unit, including a multi-effect falling film evaporator 1, the steam condensed water of the multi-effect falling film evaporator enters the absorption heat pump 2 as a driving heat source, and the circulation of the circulating hot water pool 3 The hot water enters the absorption heat pump through the pipeline, and the pipeline is provided with a circulating hot water pump 4. The circulating cold water of the absorption heat pump enters the circulating cold water pool 5 through the circulating cold water outlet pipe, and the circulating cold water of the circulating cold water pool enters the water cooler 6 through the circulating cold water pipeline. The circulating cold water pipe is equipped with a circulating cold water pump 7...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap