Soft package battery cell small module and grouping method thereof

A battery cell and module technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of no heat dissipation structure and heat dissipation measures, troublesome processing technology of small modules, difficulty in automatic production, etc., and achieve easier thermal management Realize and simplify production and installation procedures, and facilitate the effect of later maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

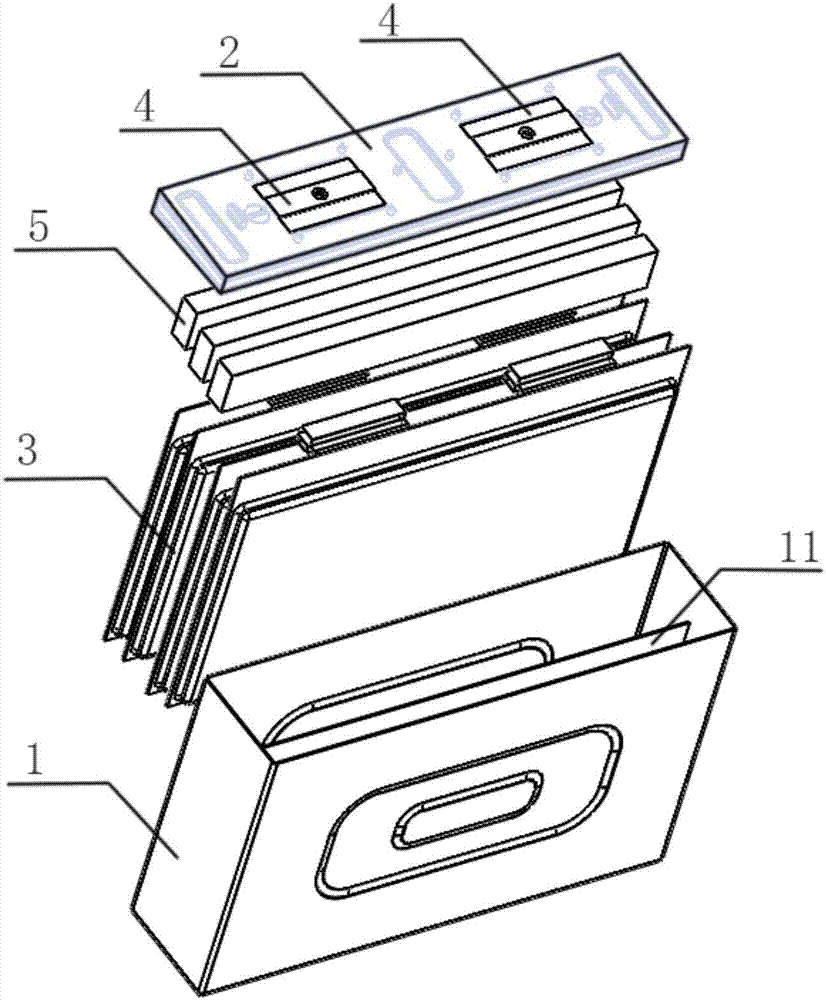

[0032] Such as figure 1 As shown, a small soft-pack battery module described in this embodiment includes a housing 1, a cover plate 2, a battery cell 3, and an electrode 4. The housing 1 is provided with a cavity with an open end. The housing 1 is provided with a partition plate 11 that divides the cavity into at least two chambers, the electric core 3 is arranged in the chamber, the cover plate 2 is connected with the casing 1 or the electric core 3 to close the chamber, and the The electrodes 4 are connected to the cover plate 2 and at least partially protrude from the outside of the cover plate 2 . The battery core 3 is provided with tabs, and the electrodes 4 are electrically connected to the tabs.

[0033] Specifically, the housing 1 is a rectangular shell with a cavity inside, an opening is set on one side of the rectangular housing 1, and the power supply core 3 is put in, and a partition plate 11 is provided in the housing 1, and the partition plate 11 can The cavity ...

Embodiment 2

[0039] This embodiment is a further limitation of the first embodiment above. In this embodiment, the housing 1 and the partition plate 11 are all made of aluminum alloy. The superior thermal conductivity of aluminum alloy can improve the heat dissipation while ensuring the safety of the battery cell 3. efficiency. Further, in order to ensure the rapid installation and automatic production of the small modules of the soft pack battery 3, the partition plate 11 adopts a flat plate with two chambers, so that one partition plate 11 divides the cavity of the housing 1 on the long side of the rectangle. The two chambers are both slender, which effectively increases the heat dissipation area of the battery cell 3, and at the same time, it is easier to confirm the installation during production and installation.

[0040] The cover plate 2 is an important part for closing the chamber and connecting the electrode 4. In order to ensure the stability of the electrode 4 and the appearan...

Embodiment 3

[0044] In this embodiment, a method for grouping small modules of soft-packed batteries includes the following steps: step S1, the housing is provided with at least two chambers for holding batteries, and the batteries are put into the chambers of the housing; Specifically, the casing is provided with a partition plate, and the partition plate divides the cavity in the casing into at least two chambers, preferably two chambers, chamber a and chamber b, respectively, and the cells are respectively placed in chamber a In the chamber and chamber b, the two cells are separated by a separator;

[0045] Step S2, paste the foamed silicone cotton on the battery cell to stabilize the battery cell and the shell or the separator; specifically, the battery cell is placed in the chamber, and there will be gaps between the battery core, the shell, and the separator plate A certain gap is pasted on the cell with foamed silicone cotton, and the foamed silicone cotton fills the gap between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com