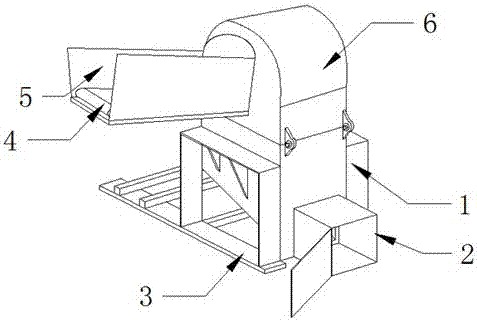

Environment-friendly branch pulverizer with containing function

A pulverizer and environmental protection technology, applied in the direction of grain processing, etc., can solve the problems of no electric transmission function, waste of human resources, no storage function, etc., to achieve the effect of saving manpower, wide application range, and improving the use of functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

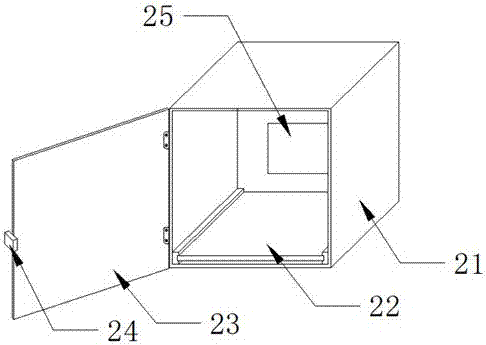

[0024] Specific implementation method: the staff crushes the discarded branches, and the crushed powder enters the holding box 21 through the discharge port 25, and is stacked on the sliding plate 22. When the holding box 21 is stacked with enough powder, the staff presses the card Buckle 24, thereby opening the box door 23 of the holding box 21, sliding the sliding plate 22 to a suitable position along the chute, after taking out the broken powder, the staff will push the sliding plate 22 into the holding box 21 again, and carry out the process again. The crushing of discarded branches avoids the crushed debris from being directly stacked outside, thereby reducing the phenomenon that the debris will be raised when encountering wind, and improving the practical and environmental protection of the present invention.

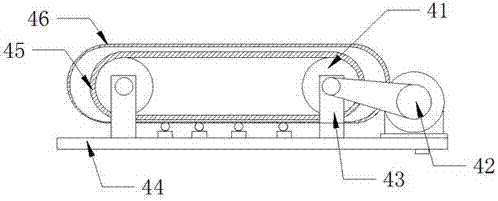

[0025] When the staff uses environmental protection tree branch crushing and crushing work, first turn on the transmission switch, the transmission switch is switc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com