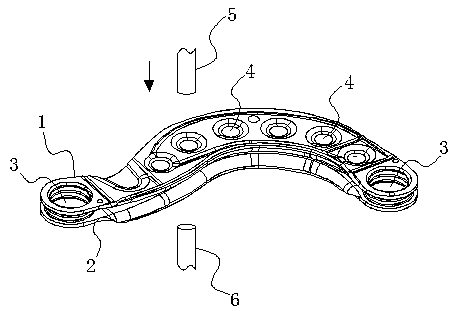

A kind of spot welding method of automobile suspension control arm

A technology of automobile suspension and control arm, which is applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of non-disclosure and reduced processing accuracy, and achieve the effect of improving processing efficiency, improving processing accuracy, and convenient and quick positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

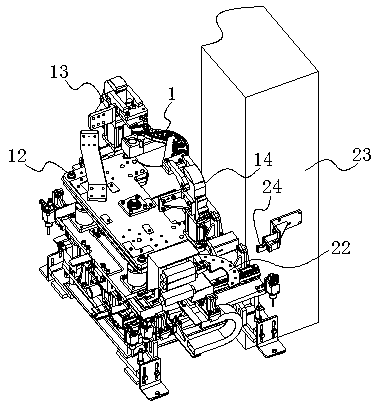

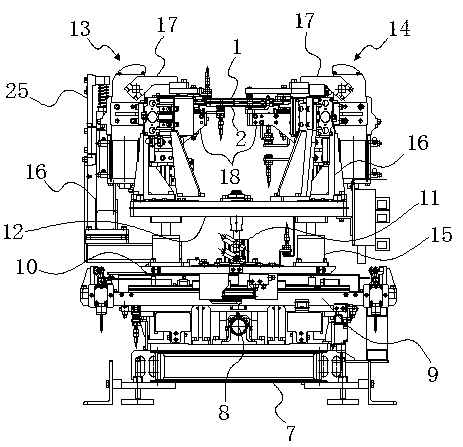

[0039] Example: as figure 2 and image 3 As shown, a method for spot welding an automobile suspension control arm, which is to set a longitudinal adjustment plate 9 on the base 7 through the screw nut mechanism one 8, and set a longitudinal adjustment plate 9 on the longitudinal adjustment plate 9 through the screw nut mechanism II (not shown in the figure). shown) a lateral adjustment plate 10 is provided on which a vertical support cylinder 11 is provided, a suspension plate 12 is provided on the piston rod of the vertical support cylinder 11, and a suspension plate 12 is provided on the suspension plate 12 for Clamp the top cover and bottom cover of the automobile suspension control arm with the first clamp arm 13 and clamp arm II 14; connect the electric proportional valve (not shown in the figure) with the intake pipe of the vertical support cylinder to adjust the vertical The intake air volume of the support cylinder makes the support force generated by the vertical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com