Preparation method of a magnetically induced self-healing nanocomposite hydrogel

A nanocomposite and self-repairing technology, applied in the field of nanomaterials, can solve the problems that the mechanical properties cannot be significantly improved, and achieve the effects of novel structure, dense cross-linked network, and high tensile stress and strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

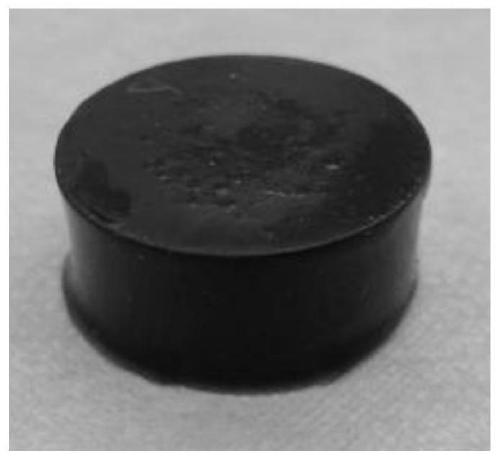

Image

Examples

Embodiment 1

[0029] 1. Add 1.35g of ferric chloride hexahydrate, 3.6g of anhydrous sodium acetate and 1g of polyvinylpyrrolidone into 40ml of ethylene glycol, stir magnetically for 30 minutes to obtain a uniform yellow mixed solution, and then pour it into a 50ml volume of polyfour In a vinyl fluoride container, react at a high temperature of 200°C for 12 hours, cool to room temperature, and successively wash with ethanol and water to obtain magnetic nanoparticles, and dry them naturally for use.

[0030] 2. Pass ammonia gas into the ethanol until it is saturated, disperse 10 mg of the magnetic nanoparticles (i.e. ferric oxide) prepared in step 1 in 30 ml of ethanol (10% ammonia gas) containing saturated ammonia gas, and mechanically stir Disperse evenly, then add 300 μ L concentration of 0.2mol / L chloroauric acid hydrate aqueous solution, mix and stir for 2 hours, the noble metal nanomaterial grows on the surface of the magnetic nanoparticle; this step synthesizes the metal nanoparticle by...

Embodiment 2

[0037] 1. Add 1.35g of ferric chloride hexahydrate, 3.6g of anhydrous sodium acetate and 1g of polyvinylpyrrolidone into 40ml of ethylene glycol, stir magnetically for 30 minutes to obtain a uniform yellow mixed solution, and then pour it into a 50ml volume of polyfour In a vinyl fluoride container, react at a high temperature of 200°C for 12 hours, cool to room temperature, and successively wash with ethanol and water to obtain magnetic nanoparticles, and dry them naturally for use.

[0038] 2. Pass ammonia gas into ethanol until it is saturated, disperse 20 mg of magnetic nanoparticles (i.e. ferric oxide) prepared in step 1 in 30 ml of ethanol (10% ammonia gas) containing saturated ammonia gas, and mechanically stir Disperse evenly, then add 600 μL of 0.2mol / L aqueous chloroauric acid tetrahydrate solution, mix and stir for 2 hours, the noble metal nanomaterials grow on the surface of the magnetic nanoparticles; this step synthesizes metal nanoparticles by reducing the noble ...

Embodiment 3

[0045] 1. Add 1.35g of ferric chloride hexahydrate, 3.6g of anhydrous sodium acetate and 1g of polyvinylpyrrolidone into 40ml of ethylene glycol, stir magnetically for 30 minutes to obtain a uniform yellow mixed solution, and then pour it into a 50ml volume of polyfour In a vinyl fluoride container, react at a high temperature of 200°C for 12 hours, cool to room temperature, and successively wash with ethanol and water to obtain magnetic nanoparticles, and dry them naturally for use.

[0046] 2. Disperse 10 mg of the magnetic nanoparticles obtained in step 1 in deionized water, then add the functional modifier allyl thiol, and perform ultrasonic treatment at room temperature for 5-10 minutes to obtain a surface-modified nanoparticle composite; the allyl thiol The added mass is 0.02% of the mass of the magnetic nanoparticle dispersion liquid.

[0047] 3. Under nitrogen protection, the monomer acrylamide and the initiator potassium persulfate were sequentially added to the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com