A membrane distillation component and system

A technology of membrane distillation and components, which is applied in the field of membrane distillation, can solve the problems of low efficiency, small flux, and high energy consumption in the membrane distillation process, and achieve the effects of increasing temperature polarization coefficient, reducing energy consumption, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

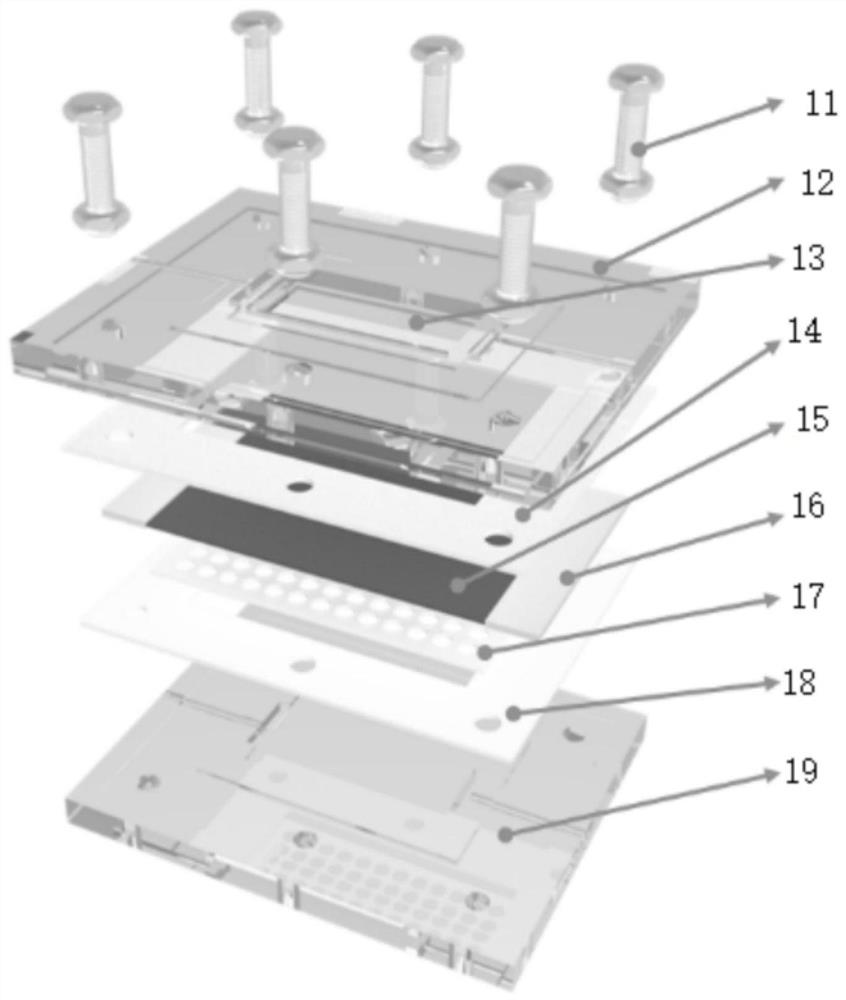

[0039] It should be noted that, in the case of no conflict, the features in the embodiments of the present invention can be combined with each other.

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

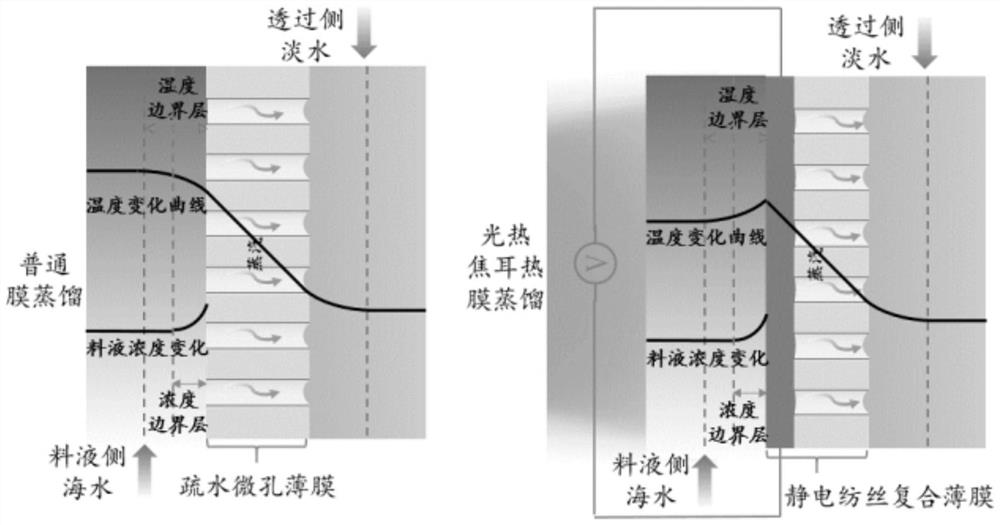

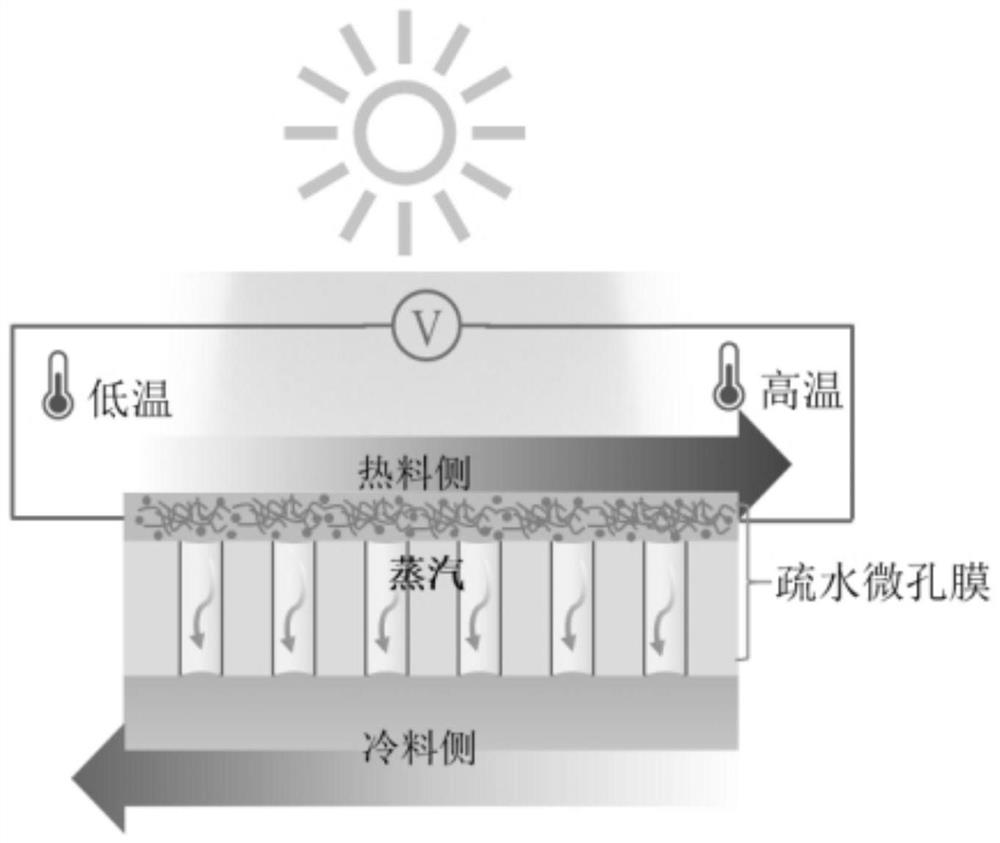

[0041] The principle of membrane distillation is: when two aqueous solutions with different temperatures are separated by a hydrophobic microporous membrane 15, under the action of the water vapor pressure difference on both sides of the membrane, water vapor on the hot side of the membrane will pass through the hydrophobic microporous membrane 15 The membrane pores enter the transfer process of the cold side of the membrane to achieve the purpose of separating the liquid-phase aqueous solution from the gas-phase water. The traditional membrane distillation system usually heats the feed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com