Buckling-restrained brace combined type embedded part construction method

A technology of buckling support and construction method, which is applied to building components, protective buildings/shelters, and earthquake resistance, and can solve the problems of difficult binding construction, installation of buckling support embedded parts that are easy to deviate, and prolonging the construction period. The difficulty and cost of construction, the effect of solving the difficulty of positioning adjustment and reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

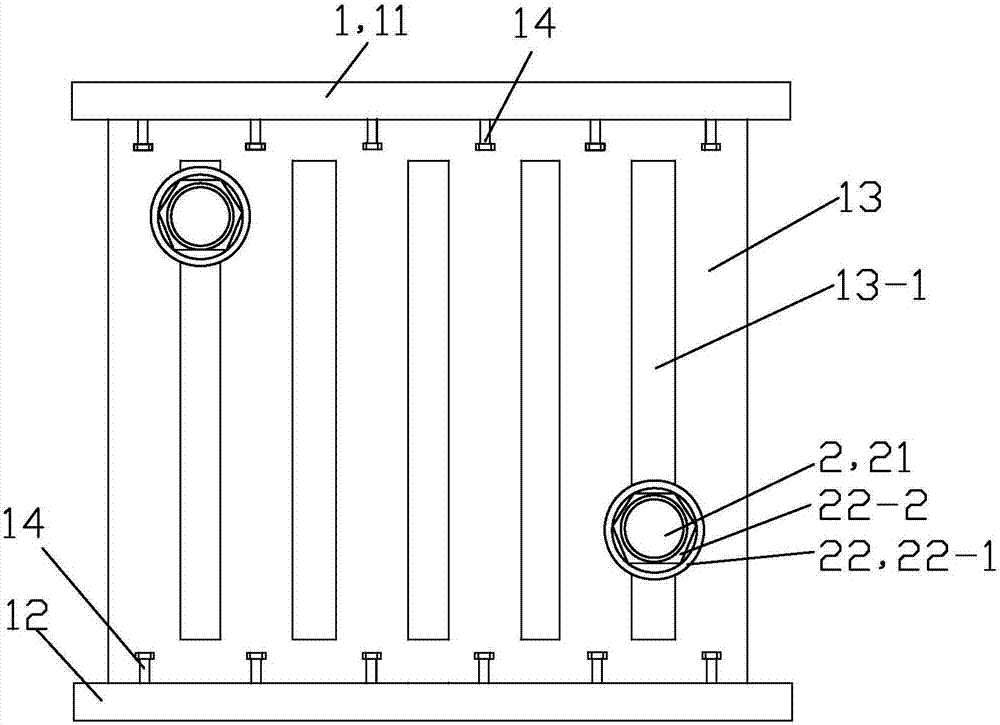

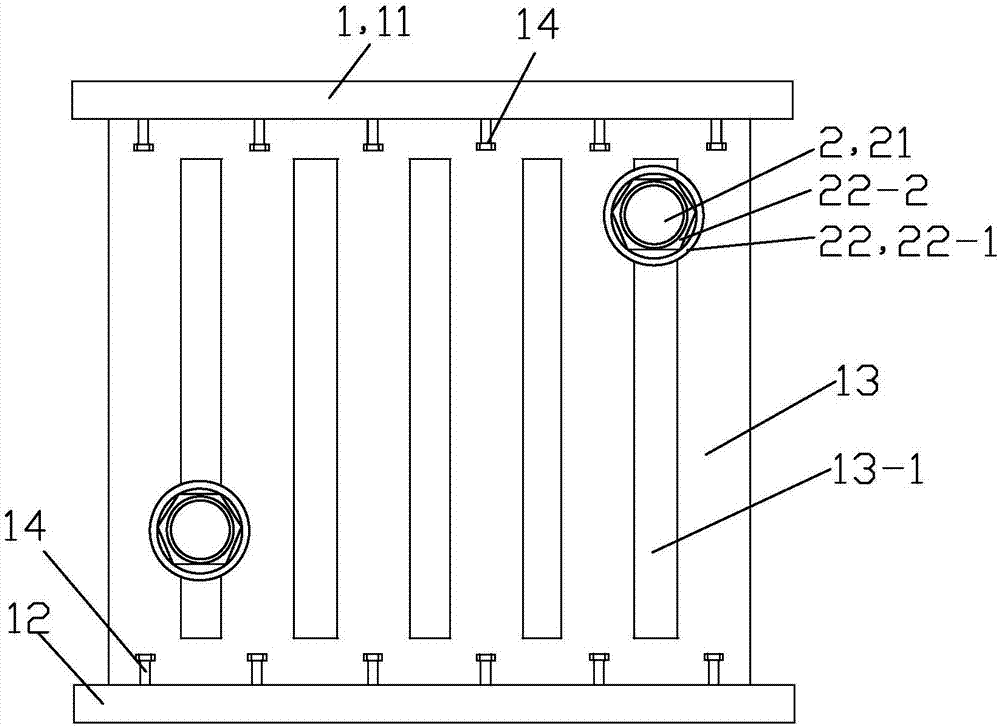

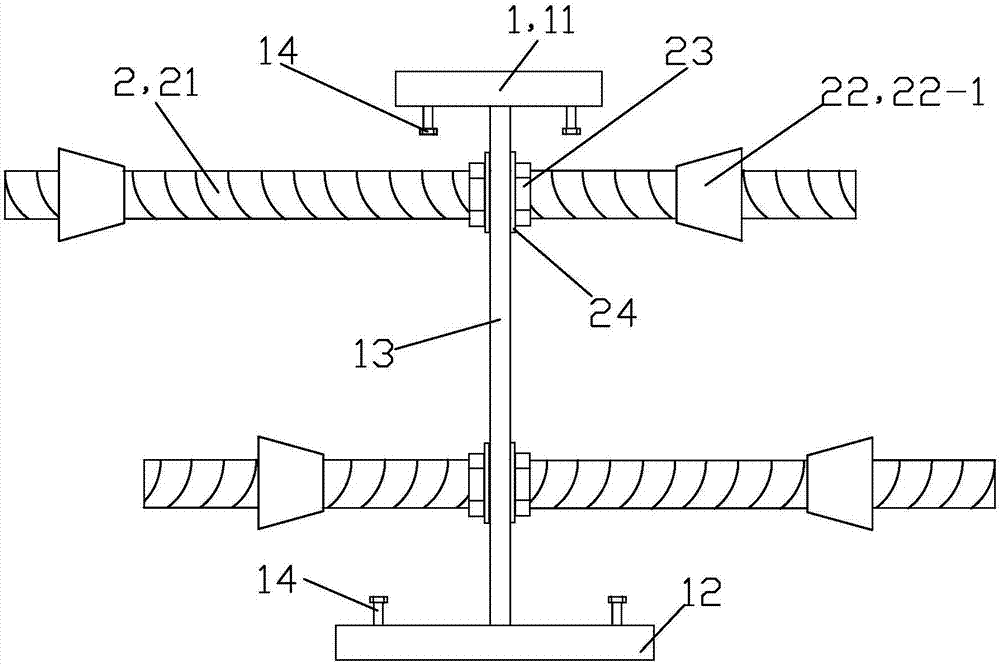

[0036] The construction method of buckling support combined embedded parts in this embodiment adopts the following methods: Figures 1 to 3 The buckling-supported combined embedded parts shown are used for construction.

[0037] See Figures 1 to 3 , the buckling support combined embedded part of this embodiment is mainly composed of an embedded part 1 and an embedded part positioning member 2 .

[0038]The embedded part 1 is composed of an upper plate 11, a lower plate 12, a web 13 and a peg 14, the upper plate 11 and the lower plate 12 are rectangular plate body parts, and the width of the lower plate 12 is greater than that of the upper plate 11; The plate 13 is a rectangular plate body; the thickness of the upper plate 11, the lower plate 12 and the web 13 is determined according to the design bearing capacity of the embedded parts; the web 13 is provided with more than two strip holes 13 arranged up and down -1, the number, width and distance of strip holes 13-1 are det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com