Workpiece surface defect detecting method based on convolutional neural networks

A technology of convolutional neural network and defect detection, which is applied in the direction of optical testing flaws/defects, measuring devices, image data processing, etc., can solve the problems of subjective test results, time-consuming, labor-intensive, and costly, and achieve the goal of reducing huge workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawings and implementation examples.

[0045] The invention provides a method for detecting workpiece surface defects based on a convolutional neural network, comprising the following steps:

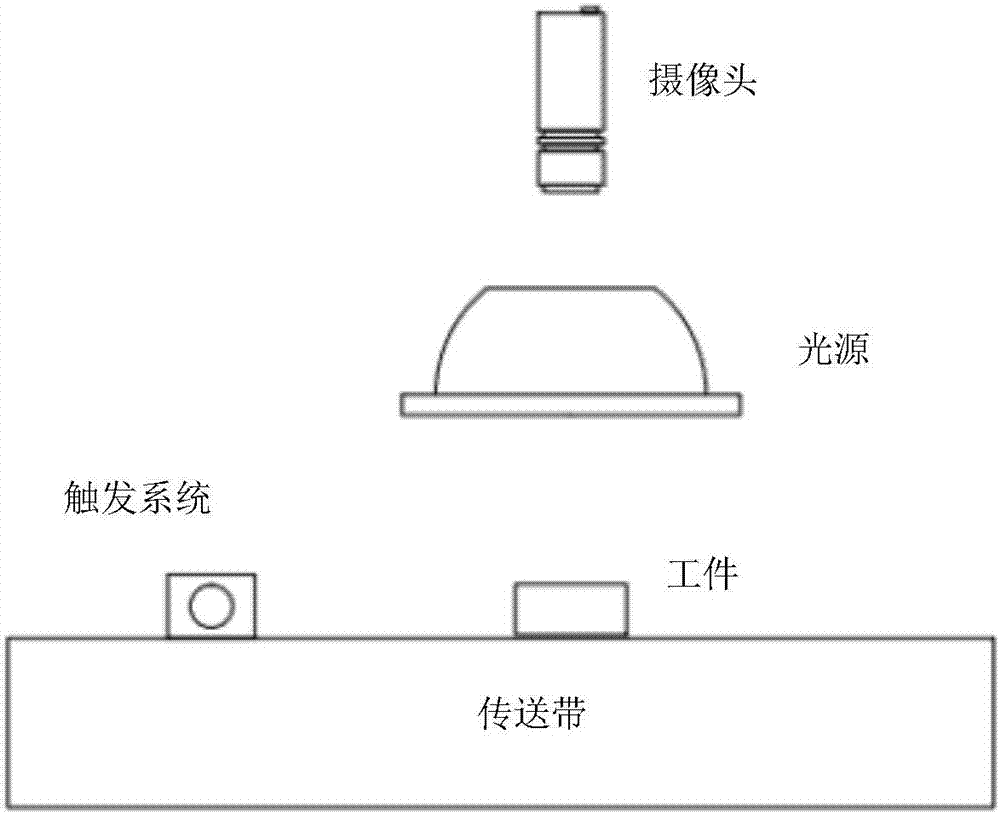

[0046] (1) Multi-channel image acquisition. Such as figure 1 As shown, the combination of multiple cameras and light sources is used to collect images of various surfaces of the workpiece. Proceed as follows:

[0047] (1.1) The camera is connected to the industrial computer through the network port or USB, and the light source is connected to the industrial computer through the serial port. This solution uses two industrial computers, and each industrial computer controls two cameras and two light sources.

[0048] (1.2) The workpiece reaches the designated position to trigger the signal switch, and the camera acquires a frame of data;

[0049] (1.3) According to the different shooting surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com