Battery temperature module manufacturing method and application

A battery temperature and module technology, used in thermometers, thermometer parts, measuring devices, etc., can solve the requirements of automatic production process, the inability of wire parts to be attached to PCB and the object to be tested, and simple operations and other problems, to achieve the effect of convenient flow installation, low price and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

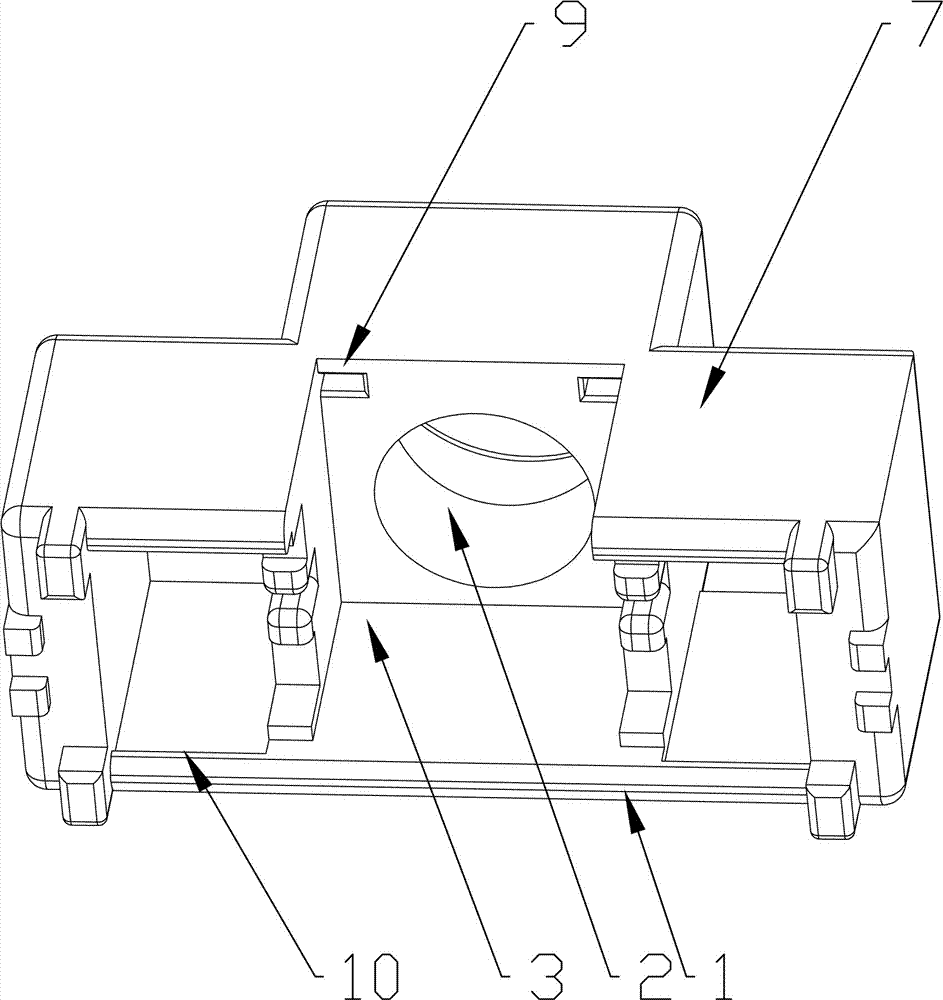

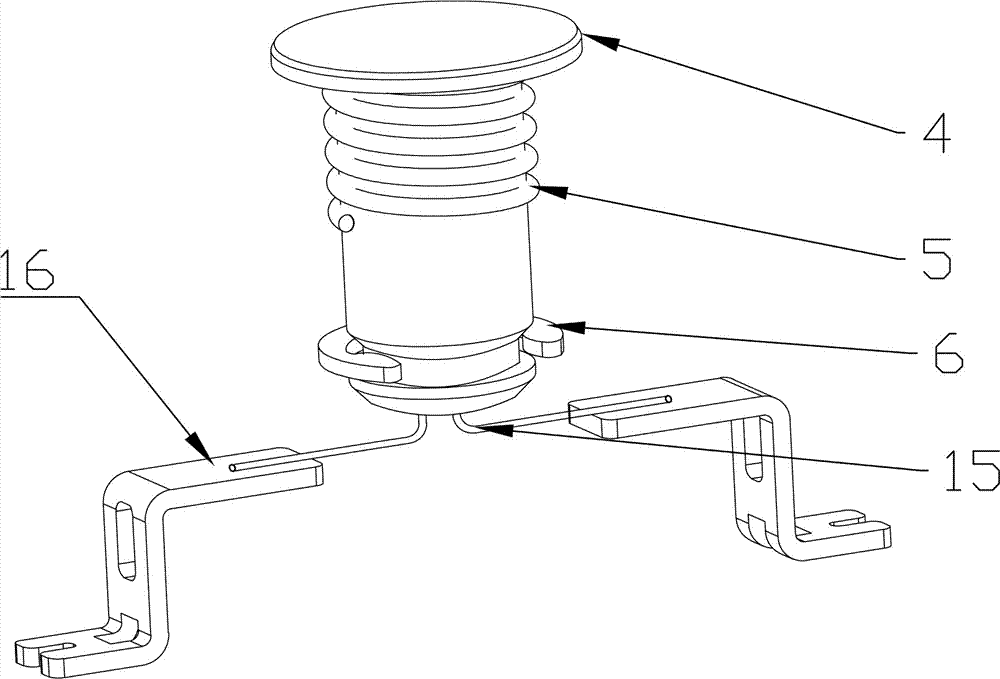

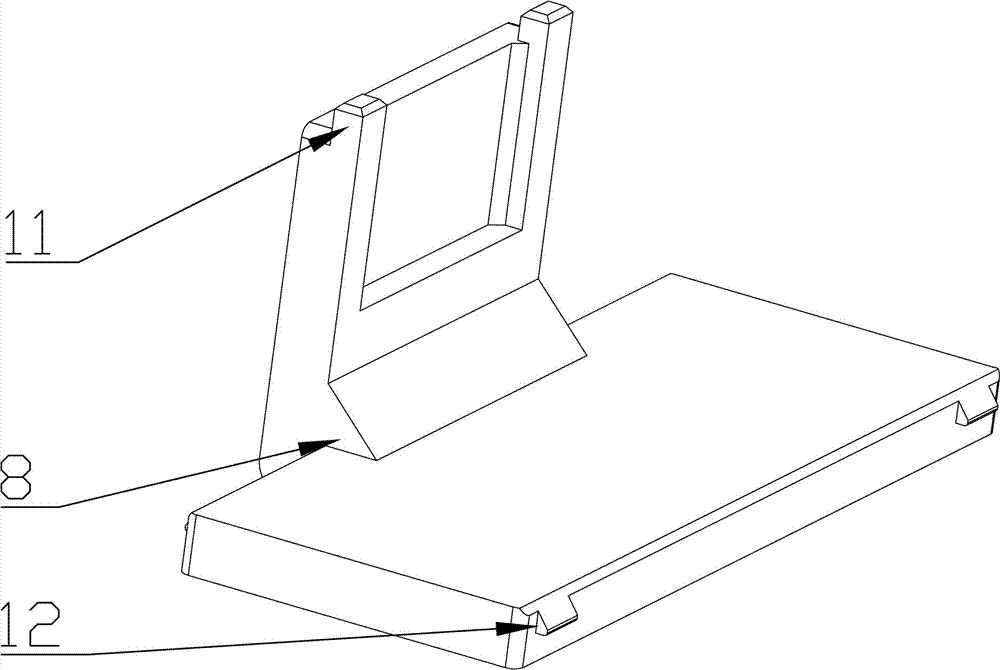

[0029] Such as Figure 1-6 As shown, a battery temperature module includes a main body 1. The main body 1 includes an upper insulating casing 7 and a lower insulating bottom cover 8. The upper insulating casing 7 and the lower insulating bottom cover 8 can be made of various insulating plastic materials. The upper part of the main body 1 is provided with a countersunk groove 2 with a larger upper diameter and a lower diameter, and a connecting groove 3 is provided at the lower part of the main body 1, and the connecting groove 3 and the countersunk groove 2 are in a communicating state. The countersunk groove 2 is provided with a metal shell 4, the material of the metal shell 4 can be aluminum, copper, stainless steel and other metals, and the outer structure of the metal shell 4 is similar to a pin, and the upper end of the metal shell 4 is provided with an arc-shaped limiting plate 4 -1. The lower end is provided with an annular groove 4-2. The limit spring 5 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com