Heat dissipation device

A heat dissipation device and heat sink technology, which is applied in identification devices, cooling/ventilation/heating transformation, instruments, etc., can solve problems such as uneven heat dissipation, chip performance degradation, and chips that cannot quickly dissipate heat, and achieve the effect of improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

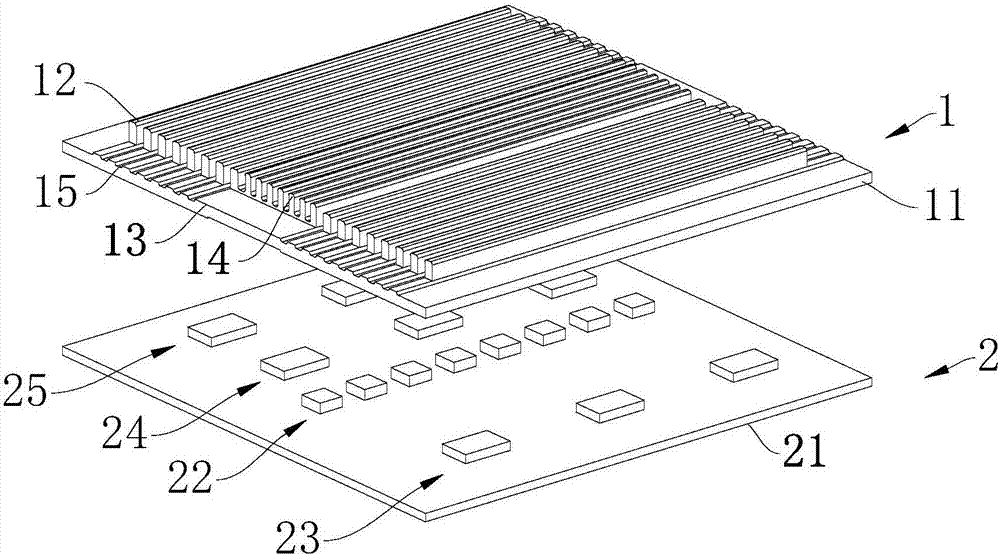

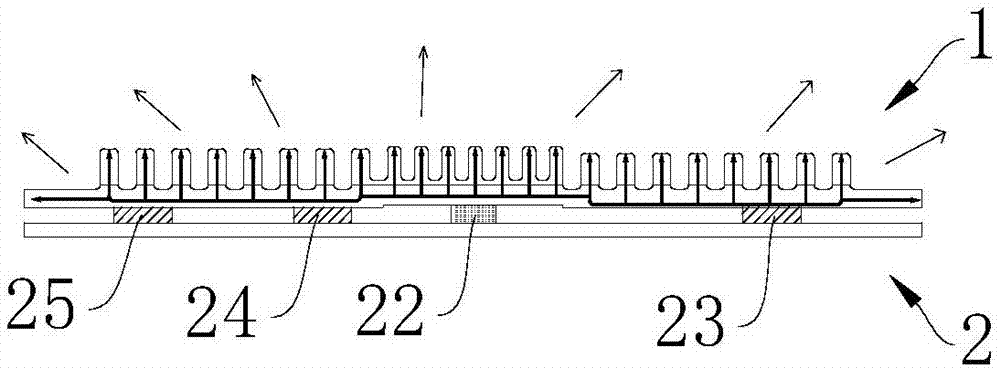

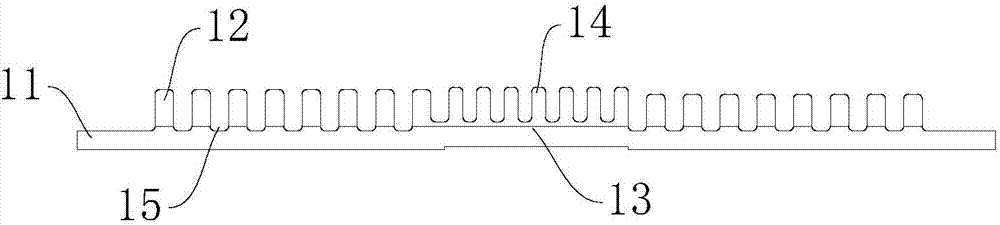

[0020] combine Figure 1 to Figure 4 As shown, a heat dissipation device in this embodiment includes a heat dissipation assembly 1 and a circuit board 2 matched with the heat dissipation assembly 1. The heat dissipation assembly 1 includes a heat conduction plate 11 and a plurality of first Heat sinks 12 are arranged in parallel and spaced between adjacent first heat sinks 12; the circuit board 2 includes a substrate 21, and a plurality of chip units arranged on the upper surface of the substrate 21, and the lower surface of the heat conducting plate 11 is closely attached to the plurality of chip units of the upper surface.

[0021] Specifically, combine figure 1 , image 3 and Figure 4 As shown, the middle part of the heat conducting plate 11 is provided with a planar protrusion 13 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com