Manufacturing method of moxibustion device

A production method and moxibustion technology, which is applied to medical preparations containing active ingredients, medical formulas, heating/cooling reflection point instruments, etc., can solve the problems of material waste, moxa sticks are easy to scatter, etc., and achieve enhanced moxibustion effect , Avoid skin burns, soft texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

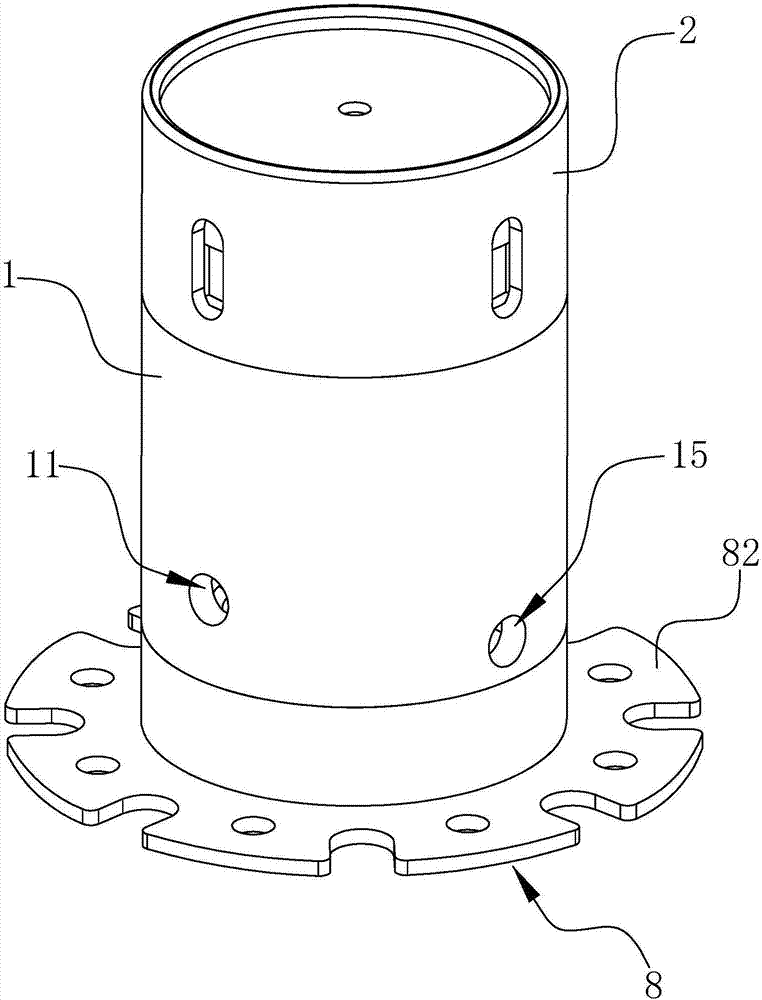

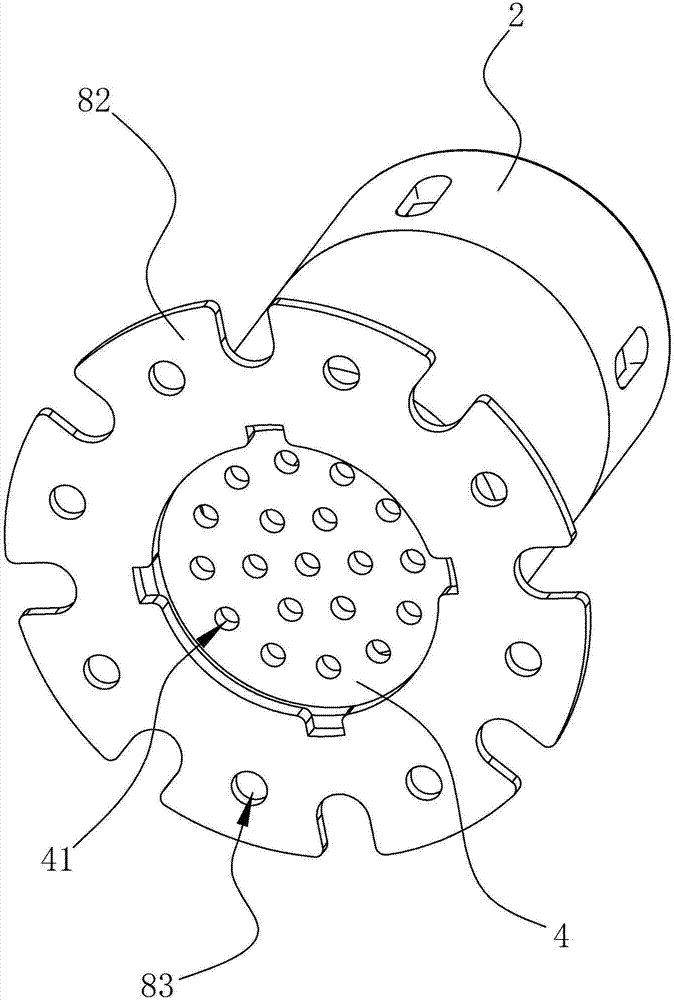

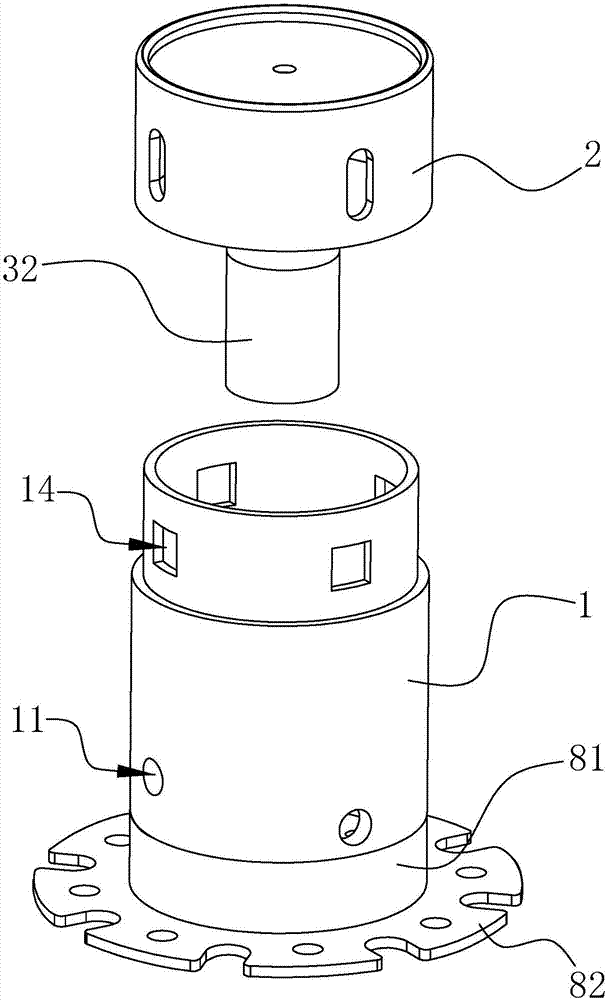

[0033] Such as Figure 1 to Figure 9 As shown, the manufacturing method of the moxibustion device of the present embodiment comprises the following steps:

[0034] 1. Prepare moxa velvet with leaves of mugwort;

[0035] Two, pile up moxa velvet on the wrapping layer, and the wrapping layer rolls up the moxa velvet to form moxa pillar 32;

[0036] 3. Place the needle body 31 of the positioning needle upwards and sequentially transport it to the bottom of the moxa pillar 32, use the moxa pillar insertion device or manually press the moxa pillar 32 into the needle body 31 to make the overall structure of the moxa pillar;

[0037] 4. Put the paper pulp made of cardboard into the cylinder body forming mold and the cylinder cover forming mold to make the cylinder body 1 and the cylinder cover 2 respectively. The ratio of the diameter of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com