Novel organic waste gas treatment method and device

A technology of organic waste gas and air inlet, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of high energy consumption, insecure safety, and inability to regenerate adsorption materials, achieving strong adaptability and occupying The effect of reduced area and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in conjunction with the accompanying drawings.

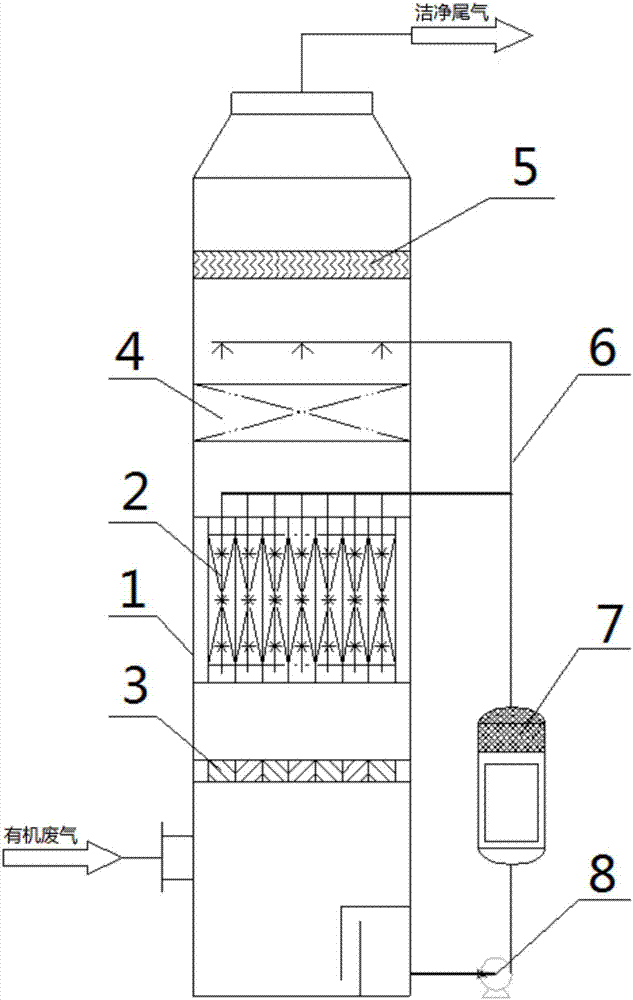

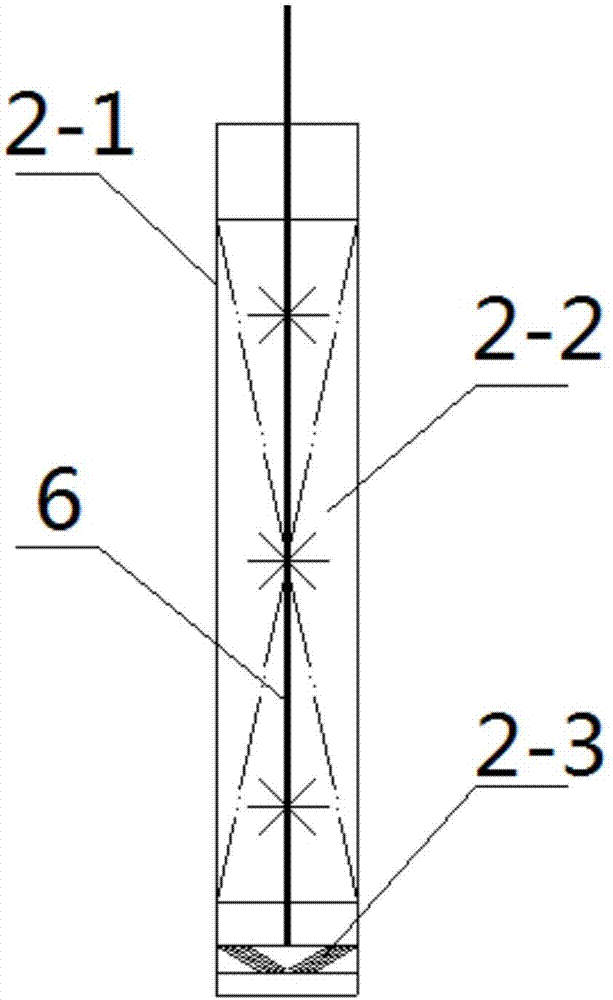

[0020] Such as figure 1 As shown, the device of the present invention includes a purification tower 1, a tube bundle purifier 2, a gas distribution plate 3, a packing layer 4, a steam-water separator 5, an active oxygen water spray pipe 6, an active oxygen water generator 7, a circulating spray The pump 8 is characterized in that: the top of the purification tower 1 is provided with an exhaust port, the bottom of the purification tower 1 is provided with an air inlet, the bottom of the purification tower 1 is provided with a water outlet, the steam-water separator 5, the packing layer 4, and the tube bundle purifier 2 , The gas distribution plate 3 is respectively installed in the purification tower 1 from top to bottom, and the gas distribution plate 3 is located above the air inlet; the active oxygen water generator 7 is installed outside the purification tower 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com